Fireproof door core plate and preparation method thereof

A fire door core board and manufacturing method technology, applied in fire doors, door leaves and other directions, can solve the problems of high scrap rate, heavy weight, high price, etc., and achieve the effects of reducing production cost, stable nature and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

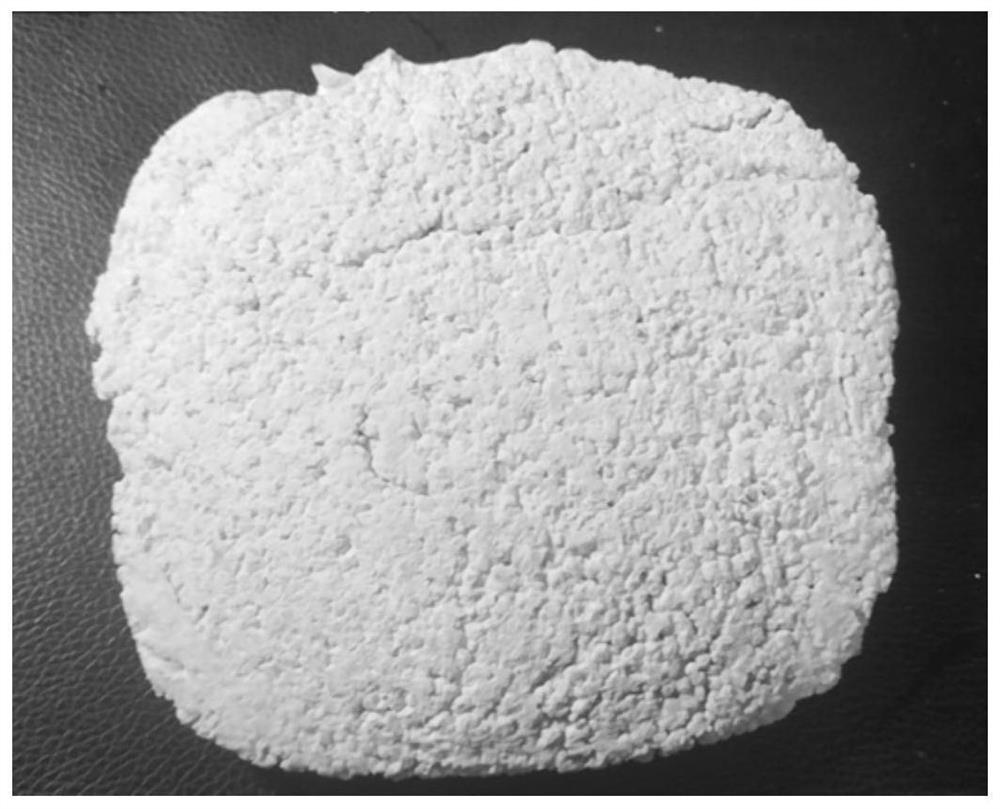

Image

Examples

Embodiment 1

[0027] A fire door core board comprises the following weight ratios: 30 parts of inorganic materials, 20 parts of water glass, 20 parts of water glass curing agent, 5 parts of ethyl acetate, 50 parts of water, 5 parts of hydrophobic agent, and the water glass is sodium water Glass. The water glass curing agent is butyl propionate, the inorganic material includes expanded perlite, the particle diameter of the inorganic material is 5mm, and the hydrophobic agent is potassium methyl silicate.

Embodiment 2

[0029] A fire door core board comprises the following weight ratios: 50 parts of inorganic materials, 20 parts of water glass, 20 parts of water glass curing agent, 5 parts of ethyl acetate, 50 parts of water, 5 parts of hydrophobic agent, and the water glass is potassium water Glass, the water glass curing agent is citric acid, the inorganic material includes: expanded perlite and ceramsite, the ratio is 2:1, the particle diameter of the inorganic material is 5mm, and the hydrophobic agent is potassium methyl silicate .

Embodiment 3

[0031] A fire door core board, comprising the following weight ratios: 50 parts of inorganic materials, 20 parts of water glass, 20 parts of water glass curing agent, 10 parts of ethyl acetate, 50 parts of water, 5 parts of hydrophobic agent, the water glass is sodium Water glass, the water glass curing agent is silicon phosphate, the inorganic material includes: expanded perlite, ceramsite, kaolin, the ratio is 2:1:1, the particle size of the inorganic material is 0.01mm ~ 3mm, the The hydrophobic agent is trimethylsilanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com