Application of additive for promoting dissolution of bauxite and adding equipment

An additive, bauxite technology, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, aluminum compound, inorganic chemistry, etc., can solve the increase of alumina production cost, increase the amount of red mud and red mud washing Water volume, evaporative salt discharge increase and other issues, to achieve the effect of improving the dissolution rate of alumina, reducing the amount of production, and eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, additive

[0029] This embodiment provides an additive for replacing lime and promoting the dissolution of alumina from bauxite. The additive consists of iron powder and ether cellulose.

[0030] In one example, in the additive, the mass ratio between iron powder and ether cellulose is (1:99)-(99:1). In one example of this example, the mass ratio between iron powder and ether cellulose is 1:1. In one example of this example, the mass ratio between iron powder and ether cellulose is 1:10. In one example of this example, the mass ratio between iron powder and ether cellulose is 1:20. In one example of this example, the mass ratio between iron powder and ether cellulose is 1:50. In one example of this example, the mass ratio between iron powder and ether cellulose is 10:1. In one example of this example, the mass ratio between iron powder and ether cellulose is 20:1. In one example of this example, the mass ratio between iron powder and ether cellulose ...

Embodiment 2

[0036] Embodiment 2, the addition equipment of additive

[0037] In order to add the additive prepared in Example 1 during the alumina production process, this example provides an adding device.

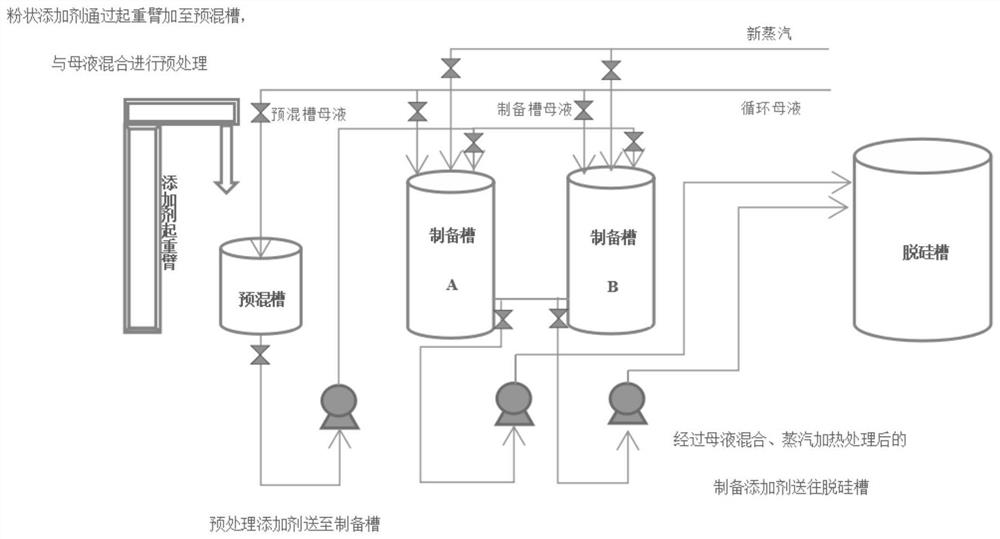

[0038] refer to figure 1 , the adding equipment includes a premix tank. Additives can be added to the premix tank, wherein the additive can be added to the premix tank at a rate of 1.1 tons / 4h. That is, the speed of adding additives to the premixing tank is: every 4 hours (h), add 1.1 tons (t) of additives.

[0039] The premixing tank communicates with the circulation mother liquor pipeline, so as to receive the circulation mother liquor from the circulation mother liquor pipeline (not shown). Among them, when the speed of adding additives to the premixing tank is 1.1 tons / 4h, the speed of circulating mother liquor pipeline to the premixing tank is 11m 3 / 4h. That is to add 11 cubic meters of circulating mother liquor to every 1.1 tons of additives.

[0040] The additive in the...

Embodiment 3

[0046] Embodiment 3, the adding process of additive

[0047] In the process of producing alumina by using diaspore type bauxite as raw material, the dosage of the additive is 0.1% of the dry ore mass of the diaspore type bauxite. In this proportion, additives in the form of solid powders can be added to the figure 1 Add a certain amount of circulating mother liquor to the premixing tank shown at the same time, and mix thoroughly by stirring and self-circulating pump. Among them, for every 1.1 tons of additives, 11 cubic meters of circulating mother liquor are added.

[0048] The premixed additive prepared in the premixing tank is pumped into the preparation tank (preparation tank A or preparation tank B) by the preparation pump. Add appropriate amount of circulating mother liquor to the preparation tank. Among them, 44 cubic meters of circulating mother liquor are added to the premixed additive prepared by every 1.1 tons of additive. Thus, an additive slurry with a solid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com