A metal double-wall detachable heat preservation cover and its manufacturing method

A manufacturing method and a technology for a thermal insulation cover are applied in the directions of thermal insulation, pipeline protection, and pipeline protection through thermal insulation, etc., and can solve the problems of easily causing skin itching or respiratory allergy, poor waterproof performance, and poor compression and bending resistance. To achieve the effect of convenient and reliable use, beautiful appearance, and harm reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

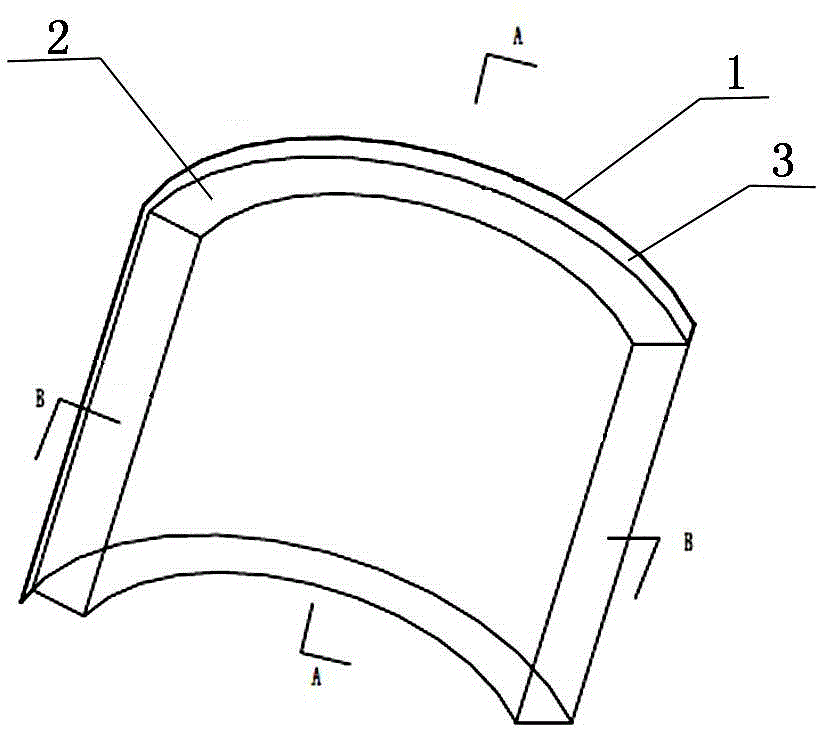

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-3 As shown, the metal double-wall detachable thermal insulation cover of the present invention mainly includes a metal shell 1 and a built-in thermal insulation layer 2, and the metal shell 1 is connected by side wall panels 3 around and outer wall panels 4 and inner wall panels 5 A block-shaped box is formed, and in the block-shaped box, there are refractory bricks stacked on top of each other and filling the inner cavity of the block-shaped box, forming at least two layers of parallel layers between the opposite outer wall panels and inner wall panels, and forming the above-mentioned Built-in insulation2. The metal double wall of the present invention includes an outer wall plate 4 and an inner wall plate 5 .

[0014] As shown in the figure, the outer wall plate 4 and the inner wall plate 5 of the present invention are correspondingly made into arc-shaped plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com