Method for preparing nano-selenium by compounding polyphenol compound and protein and prepared nano-selenium

A polyphenolic compound and protein technology, applied in the field of nano selenium, can solve the problems of difficulty in giving nano selenium other functions, loss of biological activity, poor stabilization effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: A kind of method that utilizes polyphenol compound and protein compound to prepare nano-selenium

[0035] 1) Prepare 100mM sodium selenite solution, 250mM vitamin C solution, 10mg / mL BSA solution, and 10mMEGCG solution respectively.

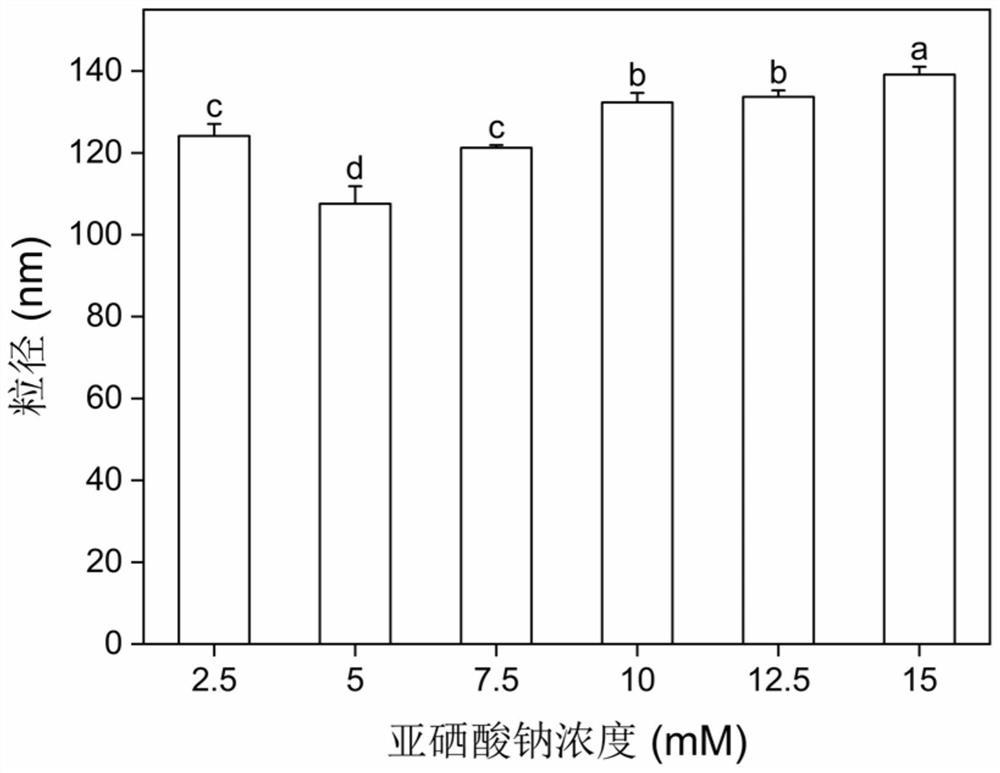

[0036] 2) The concentration of BSA in the fixed final mixed reaction system is 5mg / mL and the concentration of EGCG is 3mM, first a certain amount of BSA solution and EGCG solution are mixed to obtain the reaction system; the fixed sodium selenite and vitamin C molar ratio is 10:1, according to the concentration of sodium selenite in the final mixed reaction system is 2.5, 5, 7.5, 10, 12.5 and 15mM respectively, first add a certain amount of vitamin C solution to the reaction system, add selenous acid after mixing Sodium solution, stirred for 10 minutes to mix evenly, and left to stand at 25°C for 50 minutes to obtain a nano-selenium colloidal solution;

[0037] 3) Use 8kDa regenerated cellulose dialysis bag to dialyze the a...

Embodiment 2

[0039] Embodiment 2: A kind of method that utilizes polyphenol compound and protein compound to prepare nano-selenium

[0040] Compared with Example 1, the difference is:

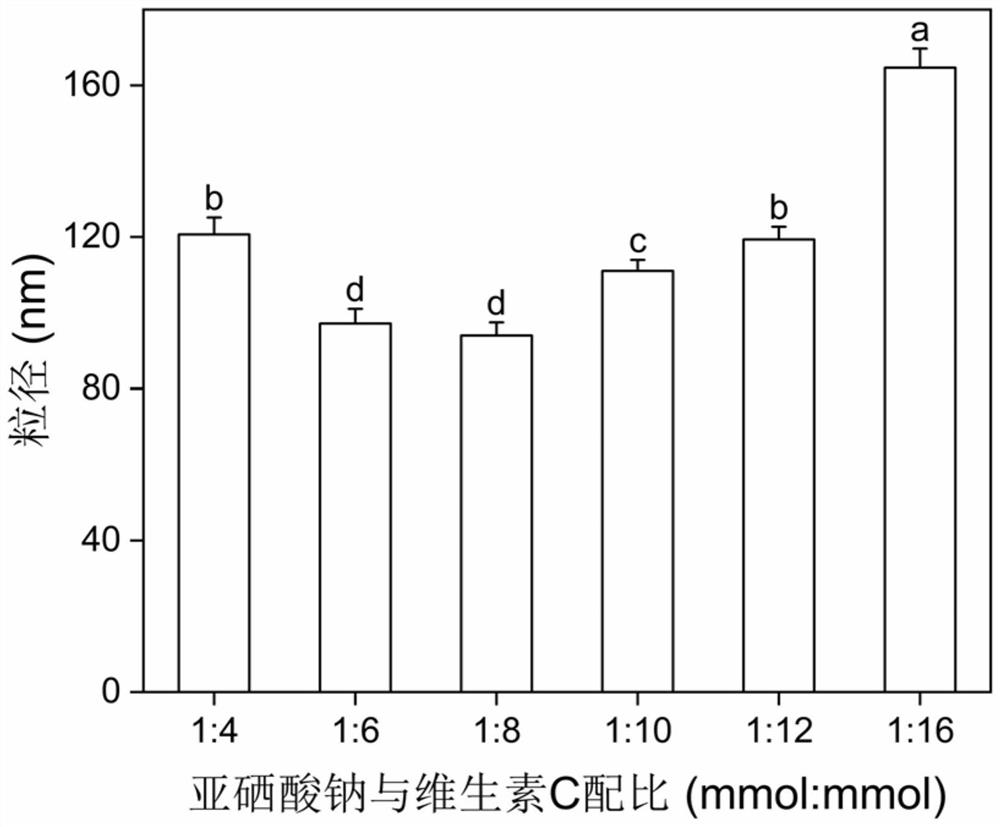

[0041] Prepare 500mM vitamin C solution, fix the concentration of sodium selenite in the final mixed reaction system to be 5mM, be 1:4, 1:6, 1:8, 1:10, respectively according to sodium selenite and vitamin C mol ratio 1:12 and 1:16 (mmol:mmol), add a certain amount of 500mM vitamin C solution, mix well, then add 100mM sodium selenite solution, stir for 10min to mix, let stand at 25°C for 50min, and get nano-selenium colloidal solution , Determination of its colloidal chemical properties, the results are as follows figure 2As shown, comprehensively considered, when the molar ratio of sodium selenite to vitamin C in the system is 1:8, the average particle size is smaller and the system is more stable.

Embodiment 3

[0042] Embodiment 3: A kind of method that utilizes polyphenol compound and protein compound to prepare nano-selenium

[0043] Compared with Example 1, the difference is:

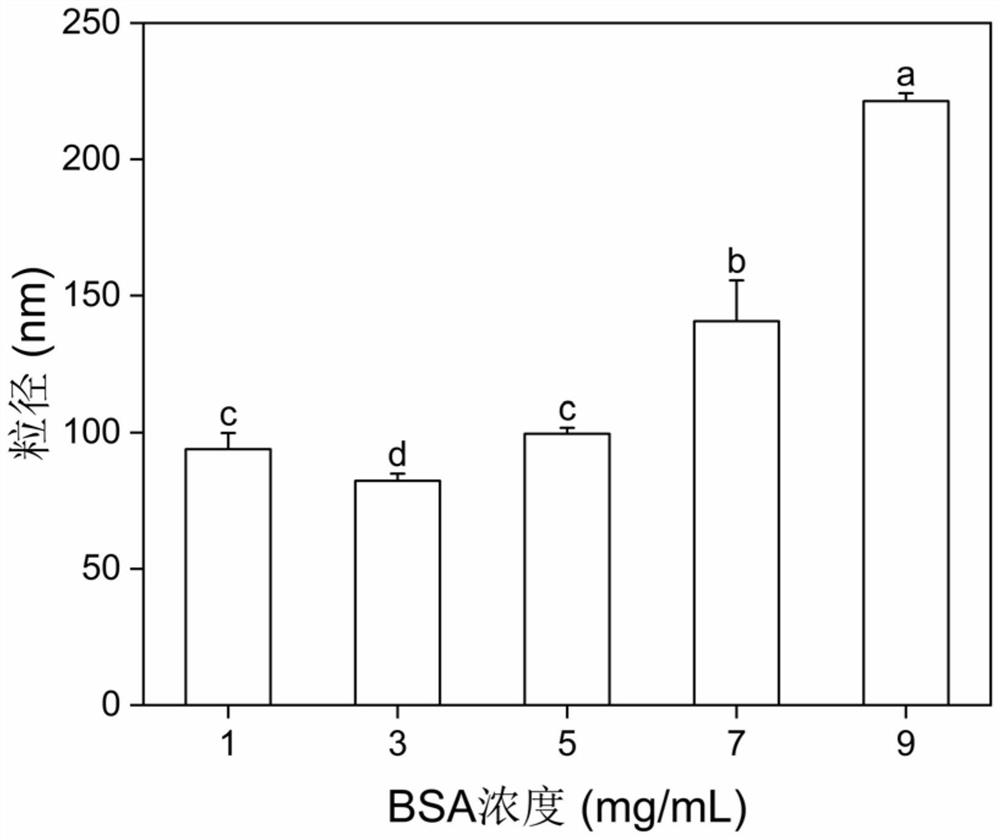

[0044] Prepare 30mg / mL BSA solution, according to the concentration of BSA in the final mixed reaction system is 1, 3, 5, 7 and 9mg / mL, mix a certain amount of 30mg / mL BSA solution with 10mM EGCG solution, and fix the final mixed The concentration of sodium selenite in the reaction system is 5mM, according to the molar ratio of sodium selenite and vitamin C is 1:8 (mmol:mmol), first add a certain amount of 250mM vitamin C solution, after mixing, add a certain amount of 100mM selenous NaCl solution, stirred for 10min to mix, left to stand at 25°C for 50min to obtain nano-selenium colloidal solution, and measured its colloidal chemical properties, the results were as follows image 3 As shown, considering comprehensively, when the concentration of BSA in the mixed reaction system is 3mg / mL, the average parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com