Method for preparing spinel structure Cu1.5Mn1.5O4 catalyst through in-situ photothermal method and application of catalyst

A cu1.5mn1.5o4, spinel structure technology, applied in the field of in-situ photothermal preparation of spinel structure Cu1.5Mn1.5O4 catalyst, can solve the problem of high cost, high energy consumption, low utilization rate of light energy, etc. problem, to achieve the effect of efficient transformation, wide range of sources, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

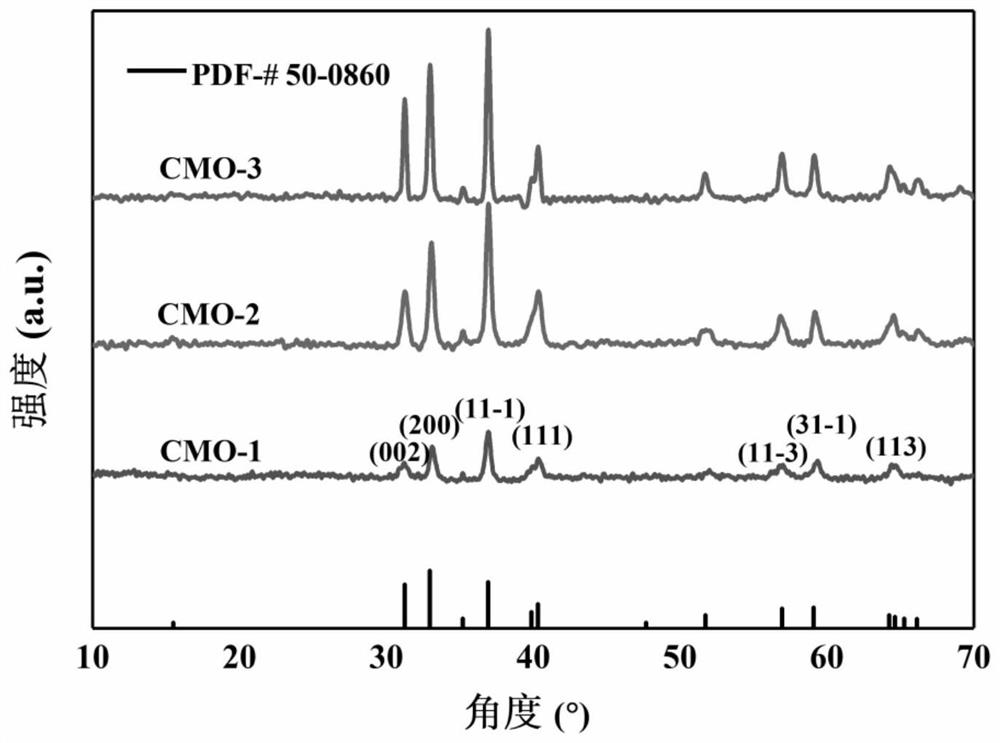

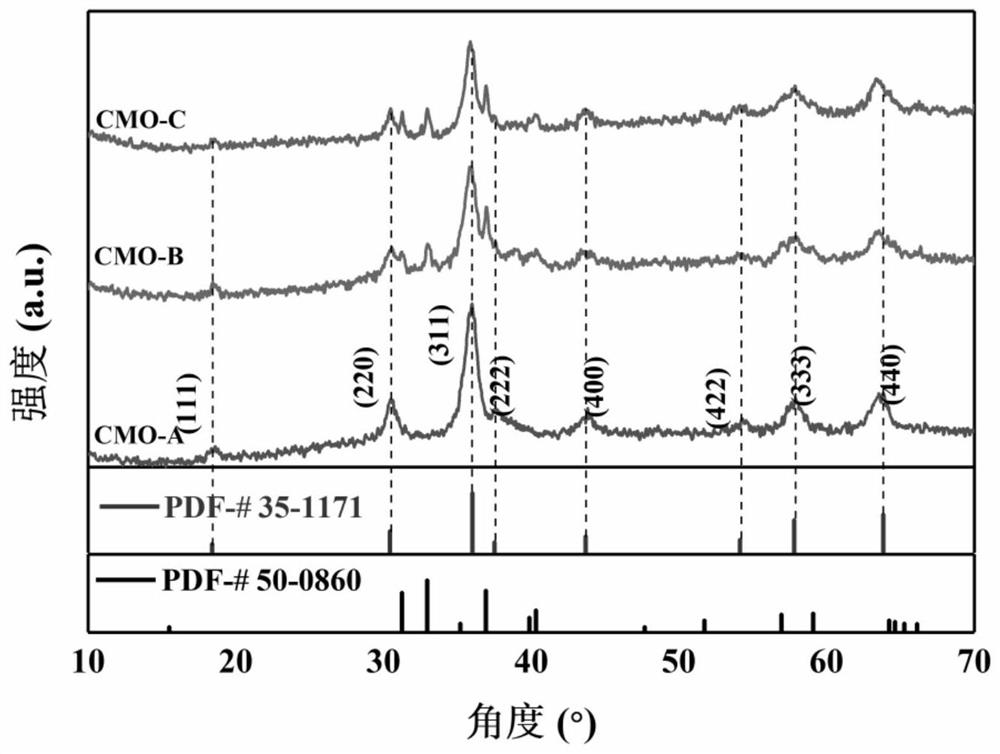

[0027] An in-situ photothermal preparation of spinel-structured Cu 1.5 mn 1.5 o 4 The method for catalyst, comprising the steps of:

[0028] 3.62g of Cu(NO3) 2 ·3H 2 O and 2.97 g of MnCl 2 4H 2 O was dissolved in 55ml of a mixed solution of deionized water and ethanol, the volume ratio of deionized water and ethanol was 4:7, stirred at room temperature to obtain a homogeneous solution;

[0029] Then 2g of CTAB (cetyltrimethylammonium bromide) and 15ml of NaOH solution with a concentration of 7mol / L were added to the solution in sequence, and stirred, and then moved into a reaction volume of 90ml. Vinyl fluoride reaction kettle, put it in a dry box for solvothermal reaction, the reaction temperature is 80°C, and the reaction time is 3-20h, to obtain CuMnO 2 Compound (denoted as CMO-1);

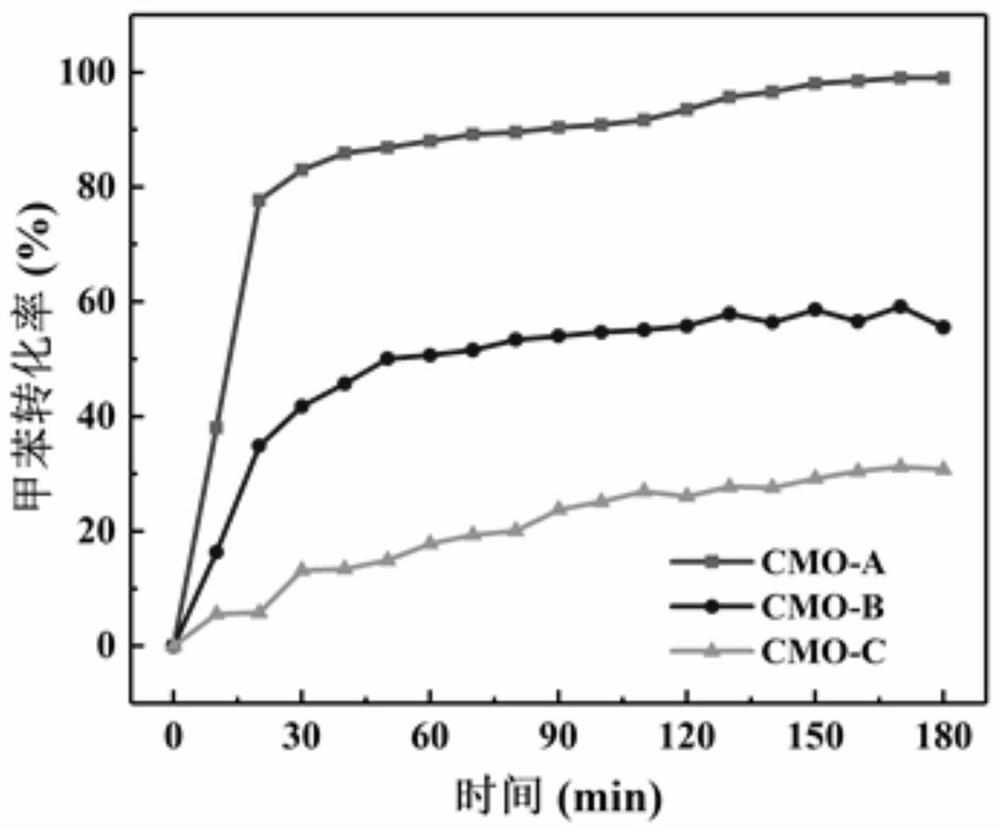

[0030] CuMnO 2 After the compound was washed and dried, it was then placed in a photothermal fluidized bed reactor and the xenon lamp was turned on, and toluene and simulated air were ...

Embodiment 2

[0035] An in-situ photothermal preparation of spinel-structured Cu 1.5 mn 1.5 o 4 The method for catalyst, comprising the steps of:

[0036] 3.62g of Cu(NO3) 2 ·3H 2 O and 2.97 g of MnCl 24H 2 O was dissolved in 55ml of a mixed solution of deionized water and ethanol, the volume ratio of deionized water and ethanol was 4:7, stirred at room temperature to obtain a homogeneous solution;

[0037] Then 2g of CTAB (cetyltrimethylammonium bromide) and 15ml of NaOH solution with a concentration of 7mol / L were added to the solution in sequence, and stirred, and then moved into a reaction volume of 90ml. Vinyl fluoride reaction kettle, put it in a dry box for solvothermal reaction, the reaction temperature is 130°C, the reaction time is 3-20h, and CuMnO is obtained 2 Compound (denoted as CMO-2);

[0038] CuMnO 2 After the compound was washed and dried, it was then placed in a photothermal fluidized bed reactor and the xenon lamp was turned on, and toluene and simulated air wer...

Embodiment 3

[0043] An in-situ photothermal preparation of spinel-structured Cu 1.5 mn 1.5 o 4 The method for catalyst, comprising the steps of:

[0044] 3.62g of Cu(NO3) 2 ·3H 2 O and 2.97 g of MnCl 2 4H 2 O was dissolved in 55ml of a mixed solution of deionized water and ethanol, the volume ratio of deionized water and ethanol was 4:7, stirred at room temperature to obtain a homogeneous solution;

[0045] Then 2g of CTAB (cetyltrimethylammonium bromide) and 15ml of NaOH solution with a concentration of 7mol / L were added to the solution in sequence, and stirred, and then moved into a reaction volume of 90ml. Vinyl fluoride reaction kettle, put it in a dry box for solvothermal reaction, the reaction temperature is 180°C, and the reaction time is 3-20h, to obtain CuMnO 2 Compound (denoted as CMO-3);

[0046] CuMnO 2 After the compound was washed and dried, it was then placed in a photothermal fluidized bed reactor and the xenon lamp was turned on, and toluene and simulated air were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com