A method to improve the mechanical properties of additively manufactured austenitic steel

An additive manufacturing and austenitic steel technology, applied in the direction of improving energy efficiency, additive manufacturing, additive processing, etc., can solve the problems of low reuse rate of raw material powder, insufficient precision of formed parts, complicated preparation process, etc. Reduce material defects, save costs, and ensure the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

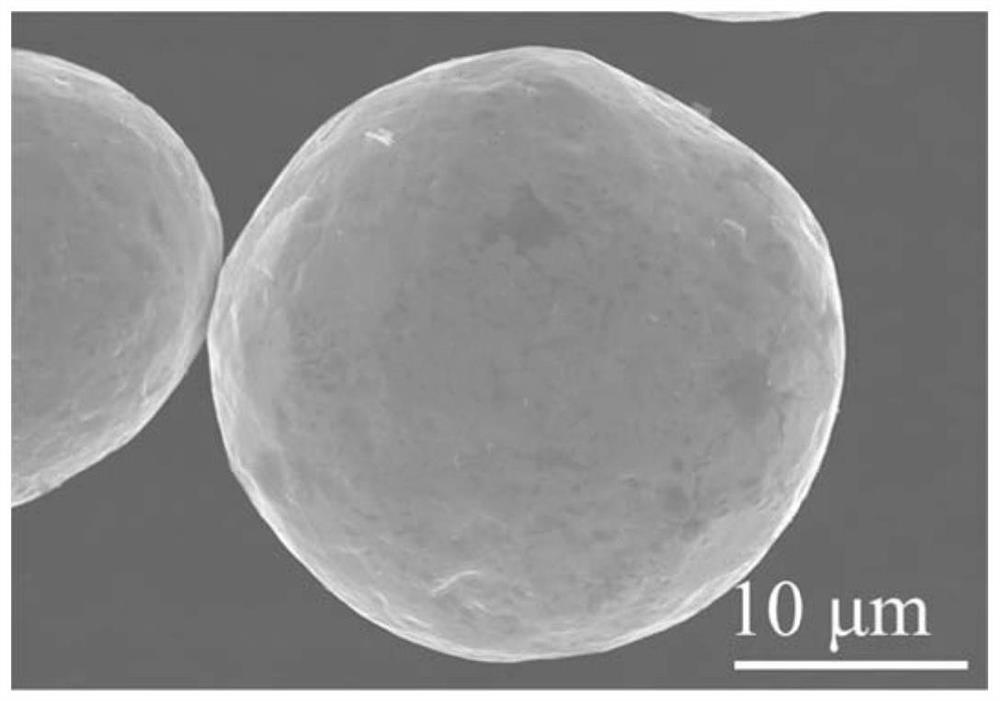

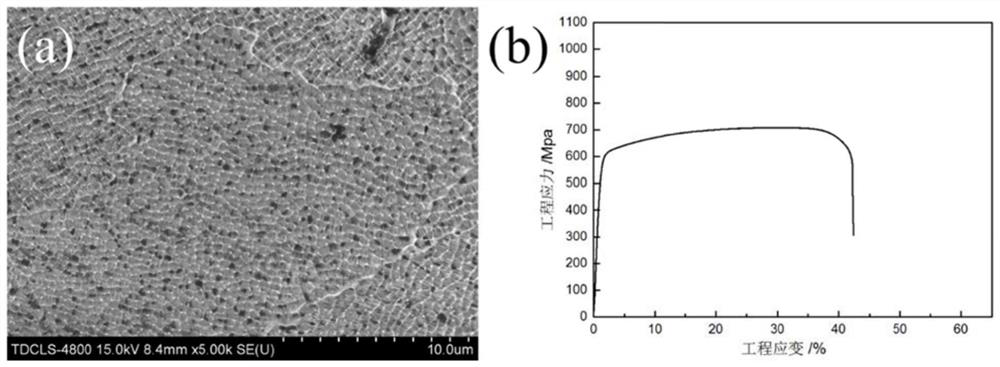

[0041] Add 23.53g of yttrium nitrate hexahydrate and 5000g of 316L spherical powder into an appropriate amount of absolute ethanol, and make the yttrium nitrate hexahydrate completely dissolve in dehydrated ethanol by mechanical stirring, and the 316L spherical powder is completely wetted in absolute ethanol , to obtain a solid-liquid mixture, dry the solid-liquid mixture, and then reduce it under a hydrogen atmosphere at 450°C for 6h to obtain a preliminary composite spherical powder, add 5g of pure yttrium powder to the preliminary composite spherical powder, and combine the pure yttrium powder with The preliminary composite spherical powder is ball milled to make it fully mixed, so as to prepare the composite spherical powder for additive manufacturing. The prepared composite spherical powder was used as a printing precursor powder, and 0.25wt.% Y 2 o 3 Composite material doped with 316L, the volume energy density used is 70J / mm 3 , the printing layer thickness is 50μm, t...

Embodiment 2

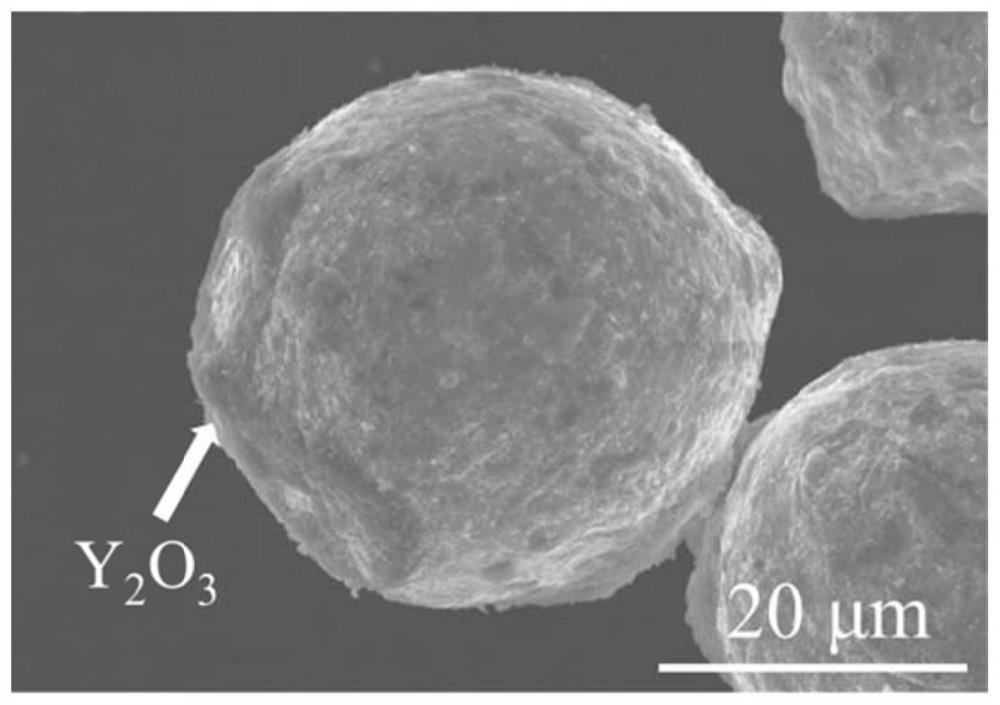

[0043] Add 170.57g of yttrium nitrate hexahydrate and 6000g of 316L spherical powder into an appropriate amount of absolute ethanol, and use ultrasonic vibration to completely dissolve the yttrium nitrate hexahydrate in absolute ethanol and completely wet the 316L spherical powder in absolute ethanol. Obtain a solid-liquid mixture, dry the solid-liquid mixture, and then reduce it under a hydrogen atmosphere at 600 ° C for 2 hours to obtain a preliminary composite spherical powder. Add 10 g of pure yttrium powder to the preliminary composite spherical powder. The composite spherical powder is ball milled to make it fully mixed, so as to prepare the composite spherical powder for additive manufacturing. The prepared composite spherical powder was used as a printing precursor powder, and 1.0wt.% Y 2 o 3 Composite material doped with 316L, the volume energy density used is 200J / mm 3 , the printing layer thickness is 50μm, the overlap between the melting channels is 10%, and the ...

Embodiment 3

[0045] Add 785.84g of lanthanum nitrate hexahydrate and 6000g of 316L spherical powder into an appropriate amount of deionized water, completely dissolve lanthanum nitrate hexahydrate in deionized water by mechanical stirring, and completely wet the 316L spherical powder in deionized water to obtain solid-liquid Mixture, dry the solid-liquid mixture, and then reduce it under a hydrogen atmosphere at 500°C for 4 hours to obtain a preliminary composite spherical powder, add 20g of pure lanthanum powder to the preliminary composite spherical powder, and compare the pure lanthanum powder and the preliminary composite spherical powder The powder is ball milled to make it fully mixed to prepare a composite spherical powder for additive manufacturing. The prepared composite spherical powder was used as a printing precursor powder, and 1.0wt.% La was prepared by selective laser melting technology (SLM) 2 o 3 Composite material doped with 316L, the volume energy density used is 150J / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com