Zirconium oxide ceramic metallized gold-based slurry, metallized layer and preparation method

A zirconia ceramic and metallization technology, which is applied in the field of metallization layer, zirconia ceramic metallization gold-based slurry, and preparation field, can solve problems such as stress concentration, difficulty in forming, and difficulty in meeting technical requirements for devices, and achieve strong adhesion , the effect of small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

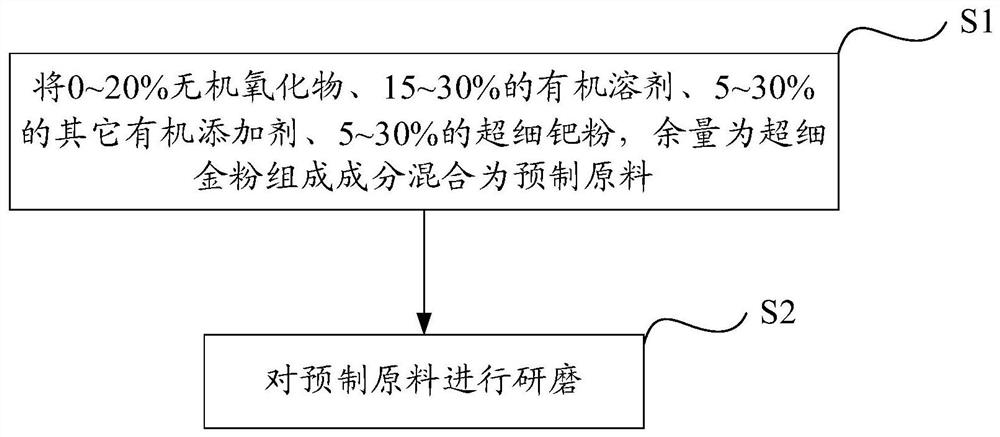

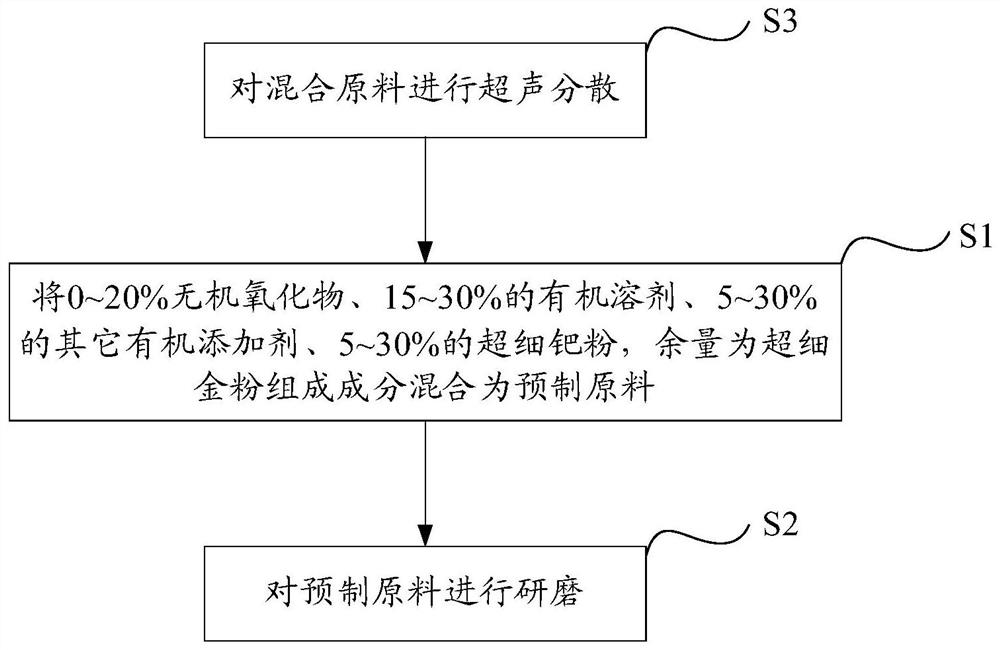

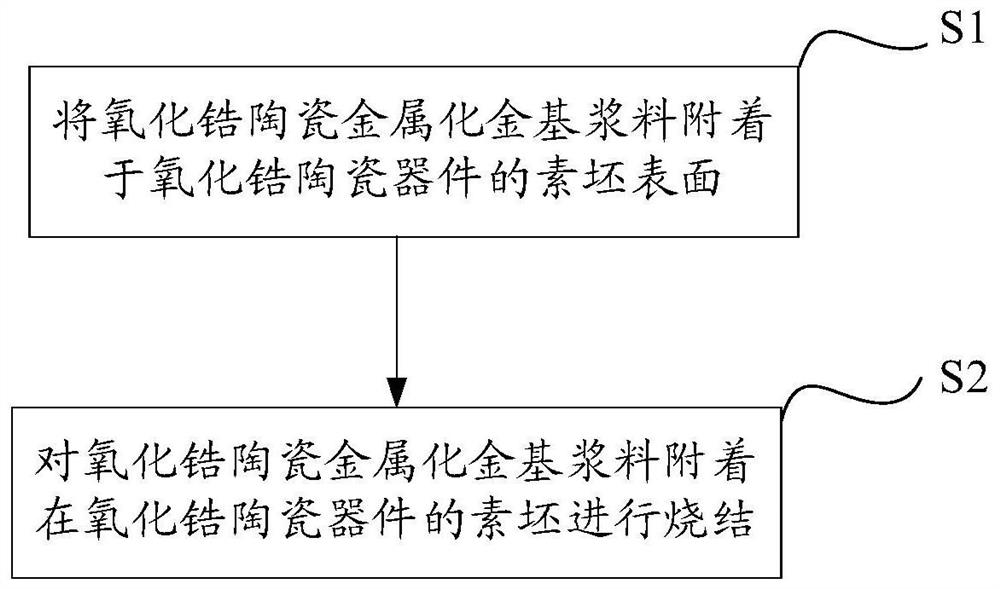

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the application and the technical features in the embodiments can be combined with each other. Undue Limitation of This Application.

[0032] In order to make the purpose, technical solutions and advantages of the embodiments of the present application clearer, the specific technical solutions of the present application will be further described in detail below in conjunction with the drawings in the embodiments of the present application. The following examples are used to illustrate the present application, but not to limit the scope of the present application.

[0033] In the embodiments of the present application, the terms "first" and "second" are used for description purposes only, and cannot be understood as indicating or implying relative importance or implicitly indicating the quantity of indicated technical features. Thus, a feature defined as "first" and "second" may explicitly or implic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com