Napkin packaging and distributing system

A napkin paper and material distribution technology, which is applied in paper product packaging, transportation and packaging, special packaging objects, etc., can solve the problems of low material distribution efficiency of napkin paper, high manual labor intensity, and high production cost, so as to improve packaging material distribution efficiency, Improve feeding efficiency and avoid the effect of bulk material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

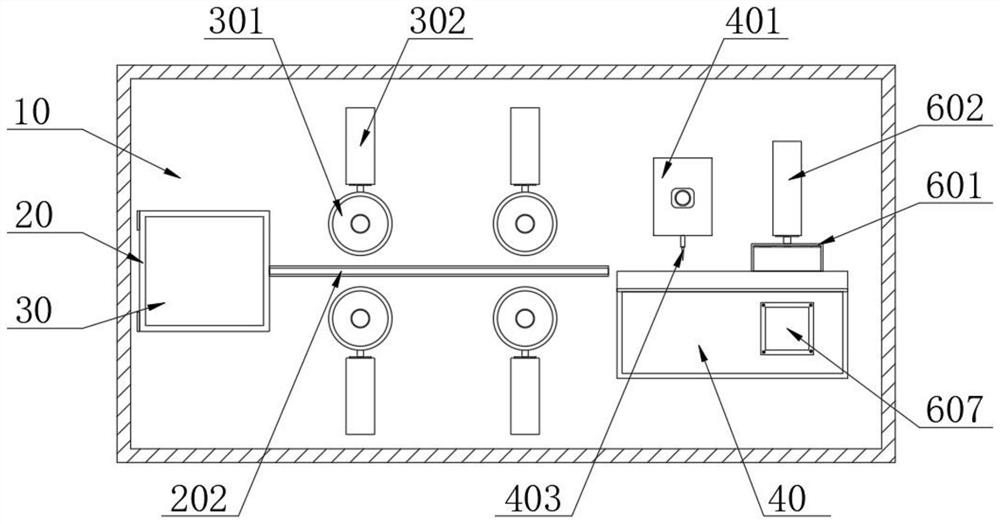

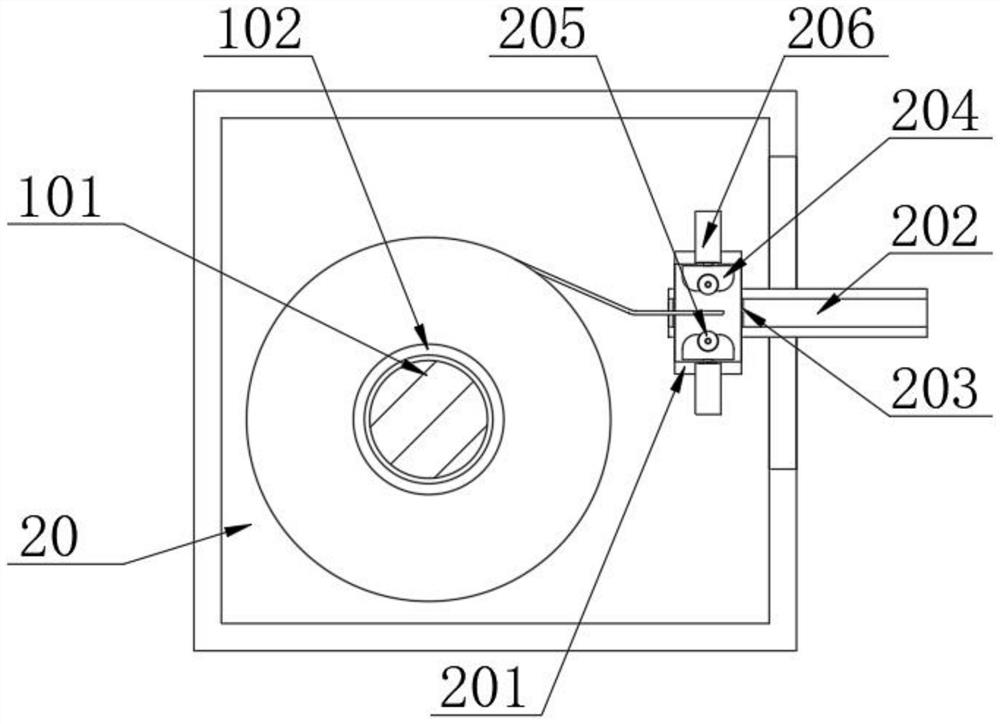

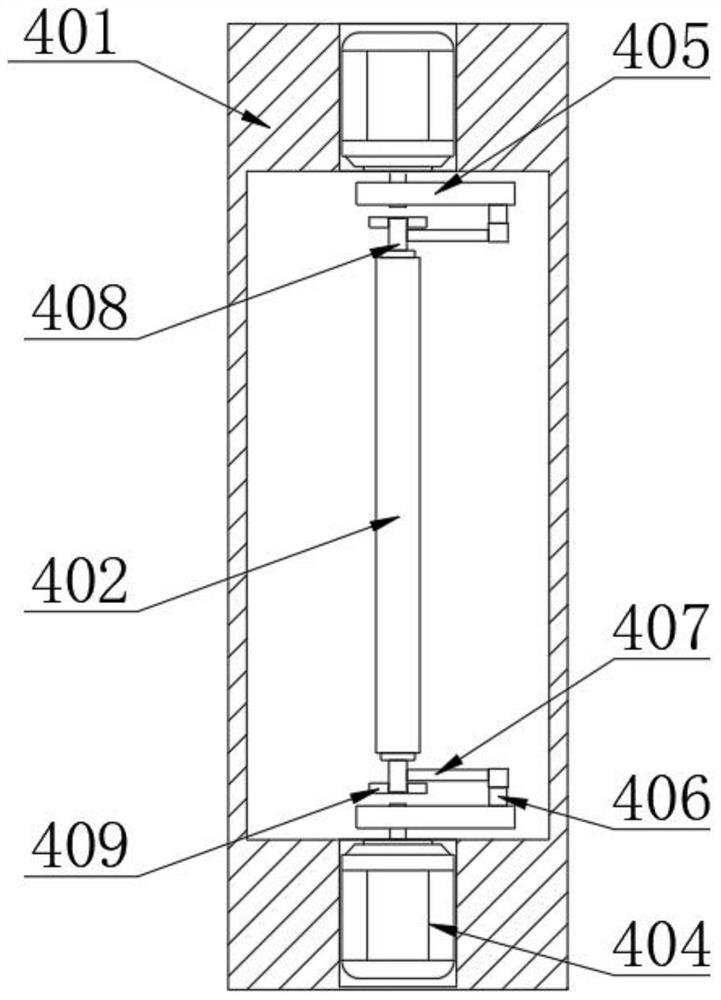

[0035] see Figure 1-6As shown, a napkin packaging distribution system includes a distribution box 10, the left side of the distribution box 10 is provided with a discharge box 20, and the front of the discharge box 20 is hinged with a box cover 30, and the discharge The inside of the box 20 is provided with a discharge assembly, and the right side of the discharge box 20 is provided with a traction mechanism, the right side of the discharge box 20 is provided with a feeding mechanism, and the right side of the distribution box 10 is provided with a fixed box 40, And the top of the fixed box 40 is provided with a material cutting mechanism, the inside of the fixed box 40 is provided with a material shifting assembly, and the right side of the fixed box 40 is provided with a discharge mechanism;

[0036] The feeding assembly packs the rolls of napkins into the discharge box 20, and the traction mechanism pulls one side of the napkins to one side of the fixed box 40, and the tra...

Embodiment 2

[0045] The material shifting assembly in the present invention includes a movable frame 501 positioned at the front and rear of the top of the fixed box 40, the front and rear of the top of the fixed box 40 are provided with linear slide rails 2 502, and one side of the two linear slide rails 2 502 is slidably provided with Two linear motors 503, one side of the two linear motors 503 are fixedly connected to one side of the two movable frames 501 respectively, and the insides of the two movable frames 501 are all movable with pneumatic fingers 504, and the upper and lower parts of the movable frames 501 are Both are provided with servo electric cylinders 3 505, and one end of the drive shafts of the two servo electric cylinders 505 is provided with a connecting frame 506, and the inside of the connecting frame 506 is fixedly connected with the surface of the pneumatic finger 504;

[0046] After the napkin is cut by the material cutting mechanism, two servo electric cylinders 3 ...

Embodiment 3

[0048] In the present invention, the discharge mechanism includes a fixed frame 601 positioned on the right side of the top of the fixed box 40. The top of the fixed frame 601 is fixedly connected with an electric push rod one 602, and one end of the electric push rod one 602 drive shaft is provided with a pressing plate 603, and the fixed box The right side of 40 tops and the below that is positioned at fixed frame 601 are provided with movable plate 604, and all around inside movable plate 604 are provided with slide bar 605, and the front and rear of fixed box 40 inside are all provided with electric push rod two 606, and two One end of an electric push rod two 606 drive shafts is fixedly connected with the front and rear sides of the movable plate 604 respectively, and the right side of the fixed box 40 front is provided with an electric push rod three 607, and one end of the electric push rod three 607 drive shafts is provided with a pushing material. plate 608;

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com