A curved capillary wave propeller and preparation method and propulsion system

A capillary wave and thruster technology, applied in the field of mechanical engineering, can solve problems such as limited capillary wave amplitude, low capillary wave strength, and limited propulsion capacity, and achieve the goal of increased Coulomb force, improved propulsion capacity, and strong propulsion capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

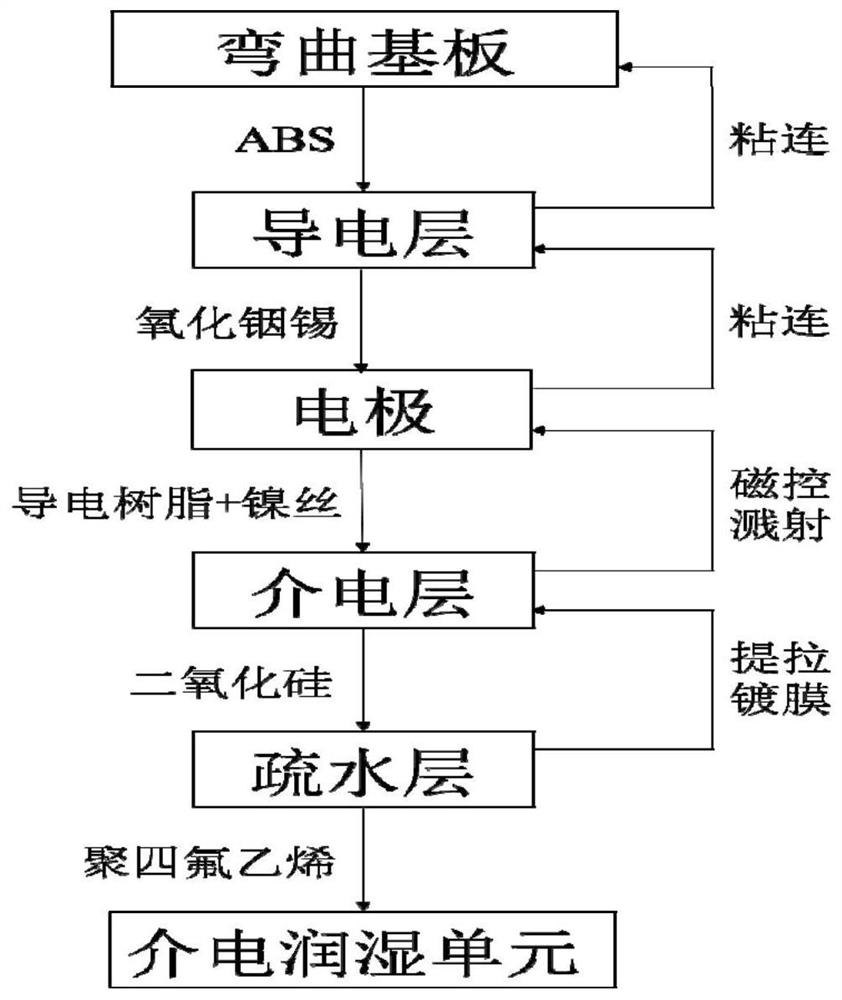

[0023] like figure 2 A preparation method of a curved capillary wave thruster is shown, comprising:

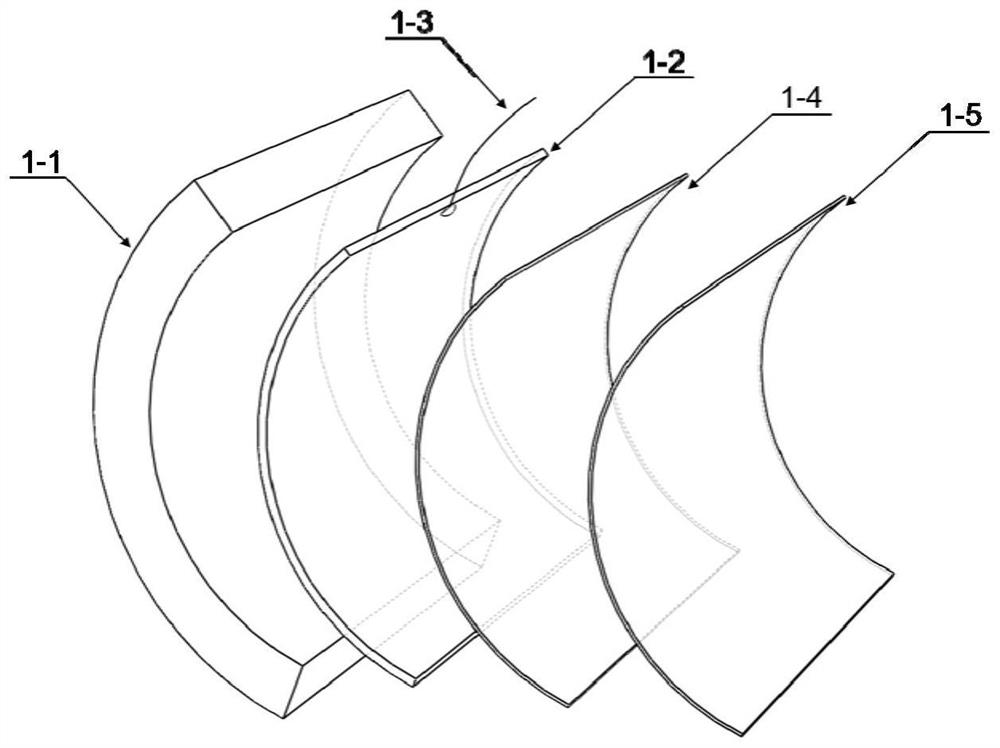

[0024] Use a 3D printer to print the ABS material into a curved substrate 1-1 with a horizontal concave 120°;

[0025] The conductive layer 1-2 is formed by magnetron sputtering indium tin oxide on the polyethylene terephthalate film, and the conductive layer 1-2 with a thickness of 0.05mm is attached to the curved substrate 1-1;

[0026] Use conductive resin to adhere the nickel wire on the conductive layer 1-2 and heat it for a certain period of time to form the electrode 1-3;

[0027] The silicon dioxide magnetron is sputtered on the upper surface of the conductive layer 1-2 with the electrodes 1-3 to form the dielectric layer 1-4;

[0028] The polytetrafluoroethylene solution was plated on the surface of the dielectric layer 1-4 to form a hydrophobic layer 1-5, and the curved substrate 1-1 with the dielectric layer 1-4 was immersed in a 5% polytetrafluoroethylene soluti...

Embodiment 1

[0032] A method for preparing a curved capillary wave propeller includes the following steps: using a 3D printer to print a curved substrate 1-1 with a curvature of 120°, using ABS as the material, and the deformation temperature of the ABS is higher than the baking temperature in the subsequent steps, which can ensure The substrate is not deformed during the baking process. A 0.05mm-thick conductive film with indium tin oxide on the surface was adhered to the above-mentioned curved substrate 1-1, the nickel wire was fixed on the conductive film with conductive resin at the upper end, and placed in an oven to bake at 70°C for 60 minutes. After the conductive resin is solidified, the silicon dioxide magnetron is sputtered onto the conductive resin and the electrodes 1-3 to serve as the dielectric layers 1-4 of the curved capillary wave thruster to prevent the unit from being broken down after power-on. Using polytetrafluoroethylene solution as the hydrophobic layer 1-5 of the c...

Embodiment 2

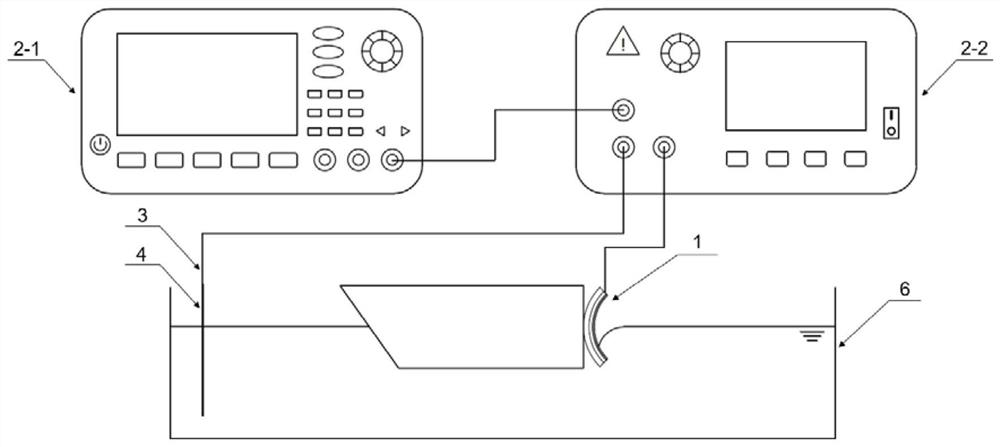

[0034] According to the operation steps of Example 1, a capillary wave propeller bent at 120° was prepared, and the curved capillary wave propeller was added to the propulsion system as a water surface propeller.

[0035] Lightweight unmanned ships and aquatic micro-robots have extremely high requirements on their own weight. Traditional propulsion devices use mechanical structures such as motors and blades, which will greatly increase the weight and complexity of the propulsion device, thereby increasing the size of the device and limiting its application scenarios. . Compared with the existing small propulsion devices, the capillary wave propulsion system based on the dielectric wetting effect does not rely on mechanical motion to achieve propulsion. When alternating current is applied at both ends of the loop, it will cause the oscillation of the liquid contact angle on the surface of the capillary wave thruster. The change of the contact angle causes the displacement of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com