Enzyme treatment method of beta-lactam antibiotics and intermediate mushroom dregs thereof

A treatment method, the technology of lactamase, applied in the direction of additional food elements, animal feed, animal feed, etc., can solve the problems of difficulty in realization, unexplained antibiotic residues, large processing volume, etc., and achieve good economic benefits and thorough treatment effects , the effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment one penicillin enzyme treatment penicillin scum

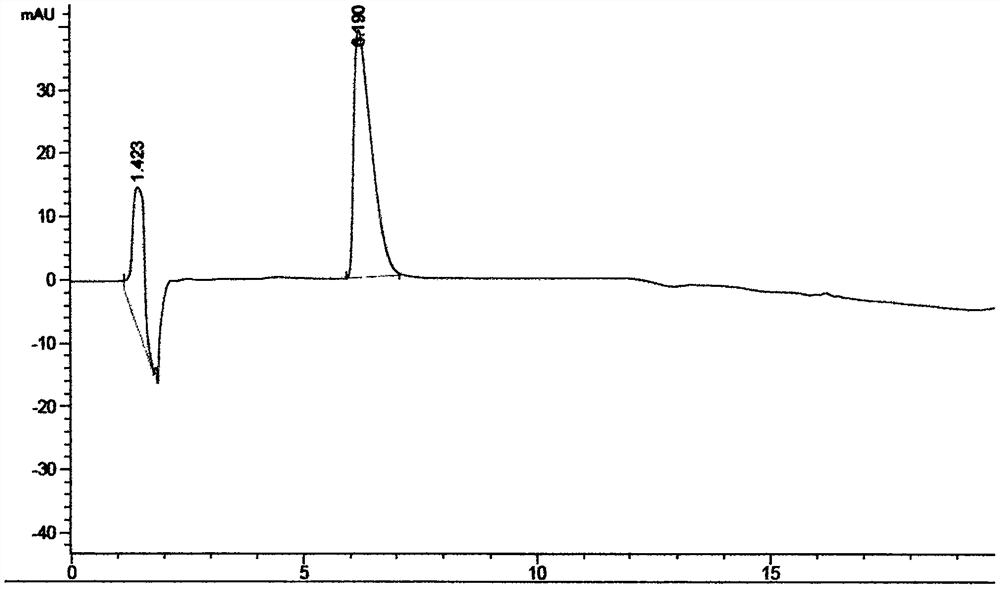

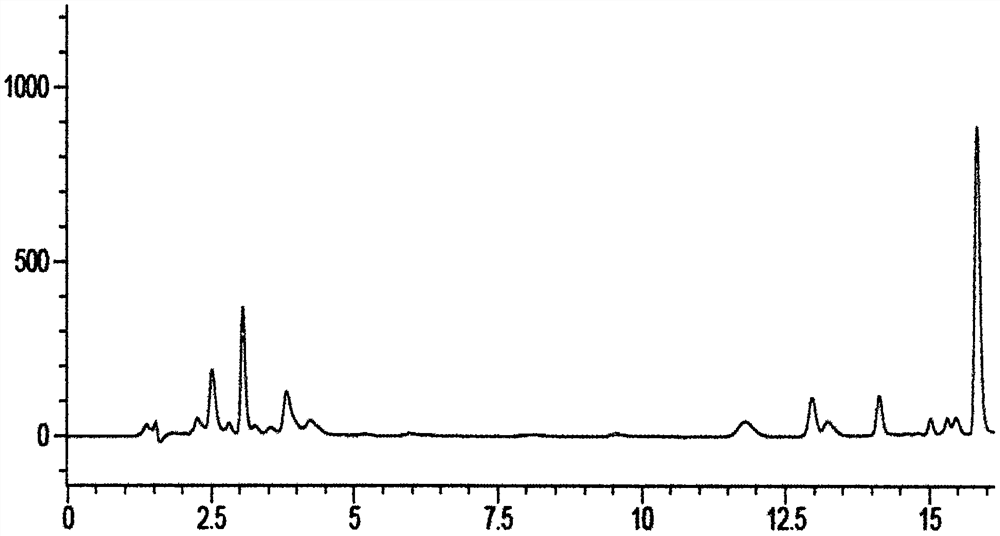

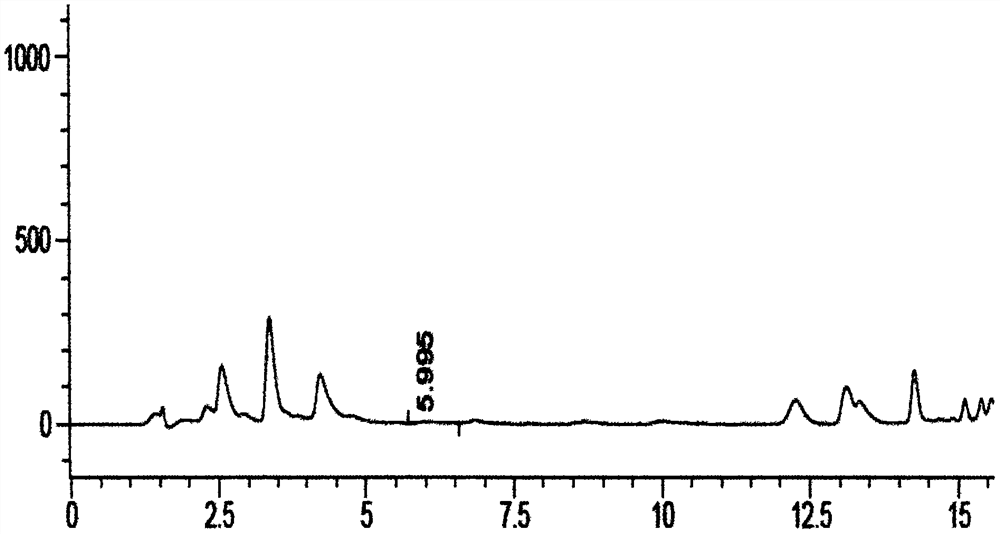

[0043] Take 1KG of penicillin residue, add 1000mL of water and stir evenly, preheat at 37°C, add 20 million units / ml of penicillinase to make the final concentration of 1000 units / ml, centrifuge at 37°C for 8 hours, take the supernatant through 0.22μm HPLC detection of residual penicillin in the filtrate after microporous membrane filtration, RP-HPLC analysis method: C18 column, mobile phase A: 0.1% TFA-H2O, mobile phase B: 0.1% TFA-CAN, gradient 0-5min, 0% B, 5~15min, 0~20B, 15~20min 20%~70%B. The decomposition results of the penicillin reference substance are shown in figure 1 . For the analysis results of the supernatant of the bacteria residue, see figure 2 , Penicillin has been completely decomposed and cannot be detected. Take the bacteria residue and centrifuge and sonicate, output power 100w, 70%, 15min, centrifuge after sonication to get the supernatant, filter through a 0.22μm microporous membra...

Embodiment 2

[0044] Embodiment two wall cracking enzyme and penicillinase treatment penicillin scum

[0045] Take 1KG of penicillin residue, add 1000mL of water and stir evenly, preheat and keep warm at 37°C, add 2g of wall-splitting enzyme, including 1g of lysozyme, 0.5g of cellulase, and 0.5g of xylanase, mix well and then heat-preserve at 37°C for 8 hours , then add 20 million units / ml of penicillinase to make the final concentration of 1000 units / ml, continue to incubate at 37°C for 8 hours and centrifuge, take the bacterial residue and centrifugal sedimentation for ultrasonic treatment, output power 100w, 70%, 15min, centrifuge after ultrasonication The supernatant was filtered through a 0.22 μm microporous membrane, and the residual penicillin in the filtrate was detected by HPLC. The results are shown in Figure 4 , undetectable penicillin residues.

Embodiment 3

[0046] Example 3 Wall-splitting enzyme and penicillinase treatment of 6-APA bacteria residue

[0047] Take 1KG of 6-APA fungus residue, add 1000mL of water and stir evenly, preheat at 37°C and keep warm, add 1g of wall cracking enzyme, including 0.4g of lysozyme, 0.3g of cellulase, and 0.3g of xylanase, mix well and keep warm at 37°C Treat for 12 hours, then add 20 million units / ml of penicillinase to make the final concentration 500 units / ml, continue to incubate at 37°C for 10 hours and centrifuge, take the bacteria residue and centrifugal sedimentation for ultrasonic treatment, output power 100w, 70%, 15min, ultrasonic Afterwards, the supernatant was obtained by centrifugation, and the residual 6-APA in the filtrate was detected by HPLC after filtration through a 0.22 μm microporous membrane, and no penicillin residue was detected as a result.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com