A circulating oxygenation biochemical device

A circulating biochemical device technology, applied in the field of circulating oxygenated biochemical device, can solve the problems of unreachable effluent and no advanced treatment module, so as to improve efficiency, maintain good balance and stability of the ecosystem, and reduce aeration and the effect of the number of aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention will be described in detail through the following examples:

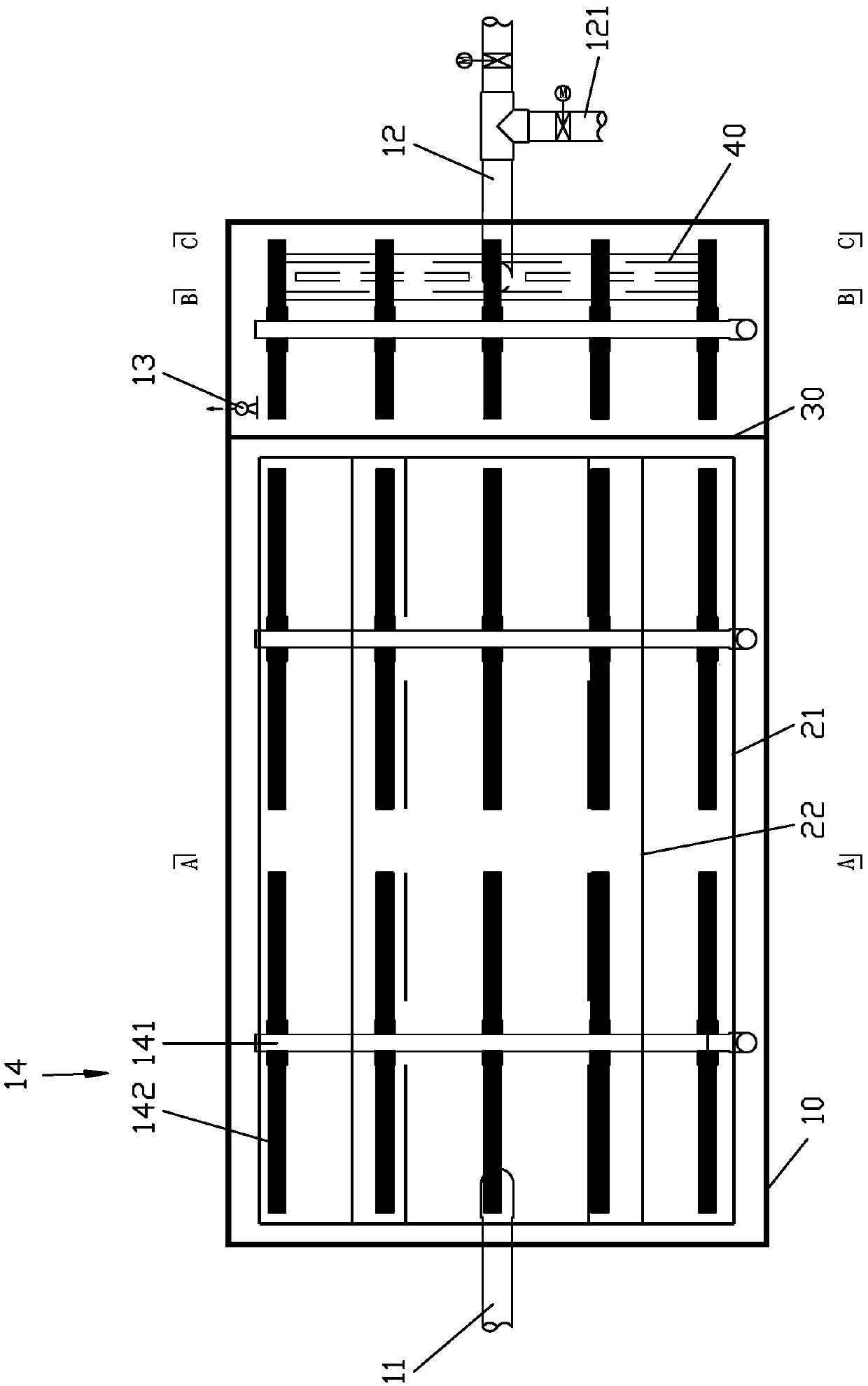

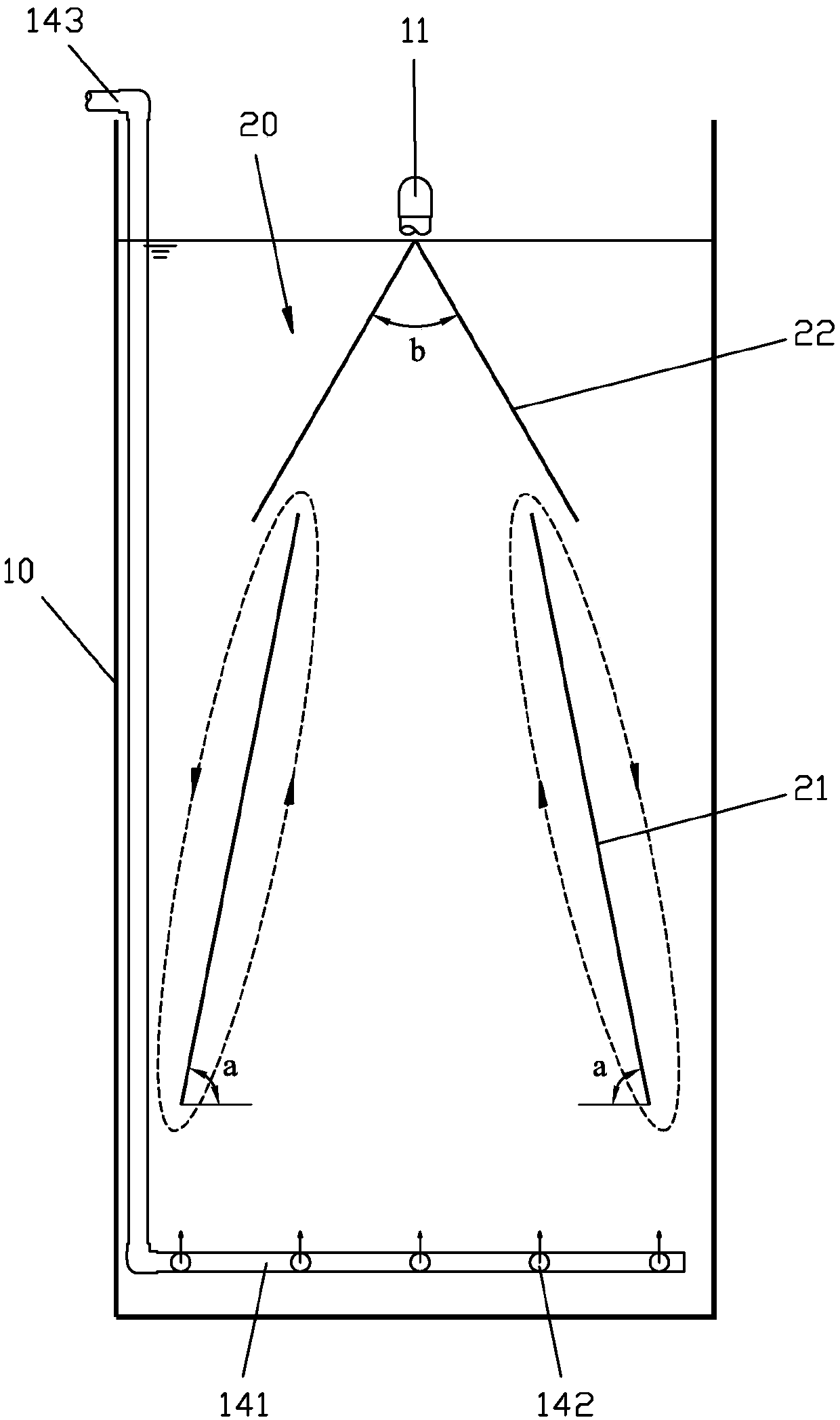

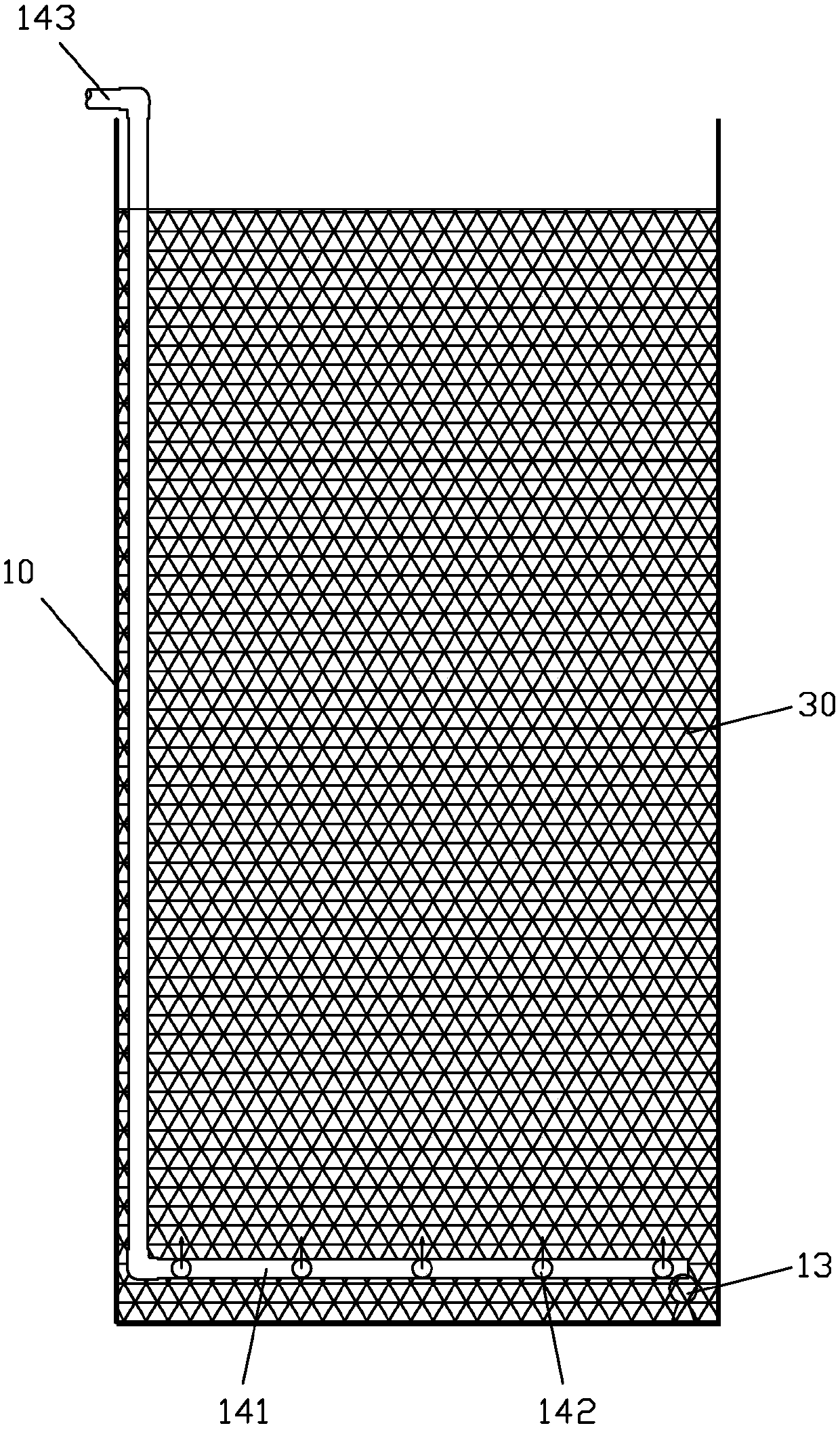

[0027] Please check Figure 1 to Figure 5 , A circulating oxygenated biochemical reactor (XCSBR), including a biochemical reaction tank 10 for sewage treatment, the biochemical reaction tank is provided with a water inlet, a decanter 40 for drainage, and a sludge discharge port; Connected to the inlet pipe 11; the decanter is connected to the outlet pipe 12, and the outlet pipe 12 is additionally provided with a branch pipe 121 for discharging the initial water from the decanter 40 to the water inlet of the biochemical reaction tank 10; the outlet pipe 12 and the branch pipe 121 are both provided There are numerical control valves; the sludge discharge port can be equipped with a submersible pump 13 to discharge the water and sludge at the bottom of the biochemical reaction tank 10; the bottom of the biochemical reaction tank 10 is laid with an aeration system 14, including a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com