Output feedback trajectory tracking control method with predetermined performance and dead zone input constraint for electromechanical system

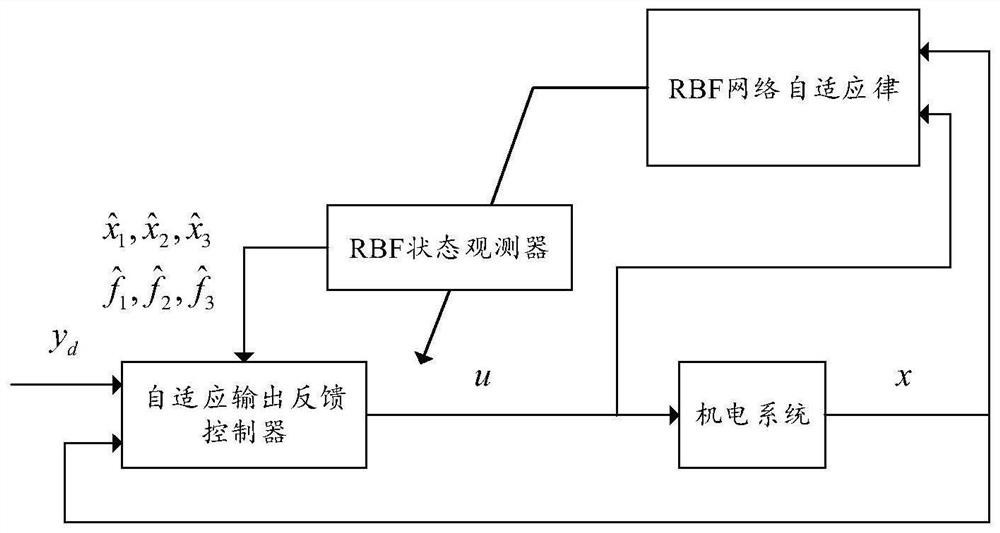

An electromechanical system and output feedback technology, applied in non-electric variable control, two-dimensional position/channel control, control/regulation system, etc., can solve the problems of difficult measurement of system state, system transient performance, etc., to solve the system state Effects of unknown and system transient, trajectory tracking, fast convergence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

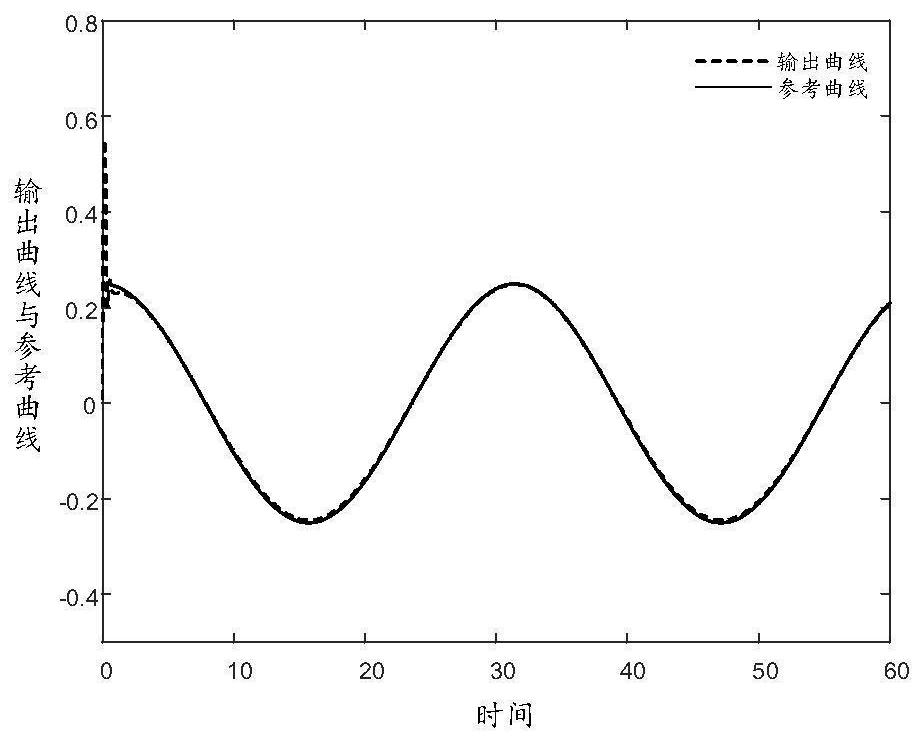

Examples

Embodiment Construction

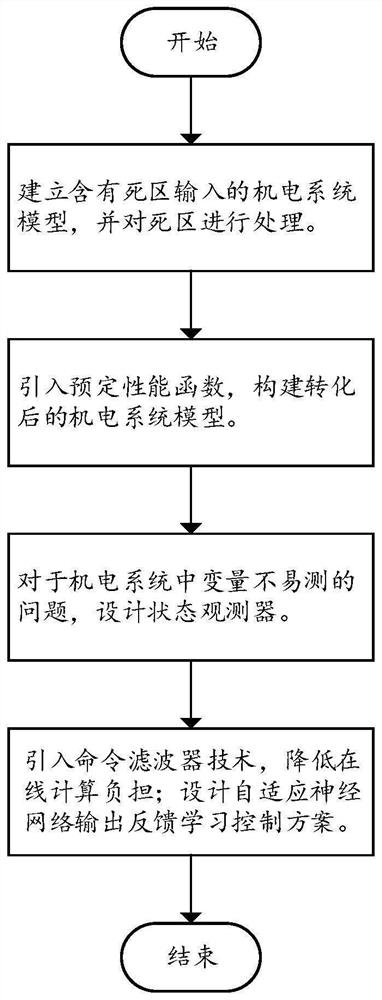

[0124] Such as figure 1 Shown, the concrete steps of the present invention are as follows:

[0125] The first step is to establish a physical model of the electromechanical system with a dead zone input, linearize the dead zone model, and give a reference tracking trajectory.

[0126]

[0127] Among them, q, Respectively expressed as the motor angular position, angular velocity, angular acceleration. I represents the motor current, V 0 Indicates the input voltage. N=mG0 g / (2K τ )+W 0 G 0 g / K τ , B=B 0 / K τ . The parameters in the electromechanical system model are shown in Table 1. in, and is bounded, its supremum satisfies Obtained from (2), (3), the model can be transformed into

[0128] u=Π(υ(t))=H T (t)γ(t)υ(t)+d(υ(t))=F(t)υ(t)+d(υ(t)) (4) Introduce state variable x 1 ,x 2 ,x 3 , so that x 1 =q is the angular position of the motor, is the motor angular velocity, x 3 = I is the motor current, the system (1) can be transformed into

[0129] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com