High-strength seamless terrace

A seamless and floor technology, applied in the direction of floors, coatings, buildings, etc., can solve the problems of poor stability, affecting the final product, and easy deformation, etc., to achieve good water resistance, improve surface strength, and enhance overall strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

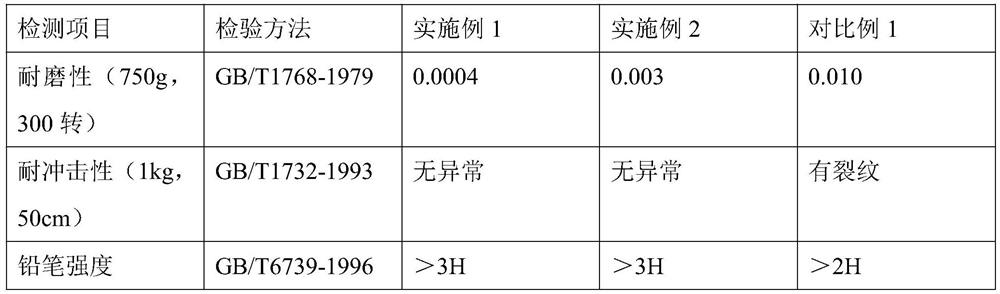

Examples

Embodiment 1

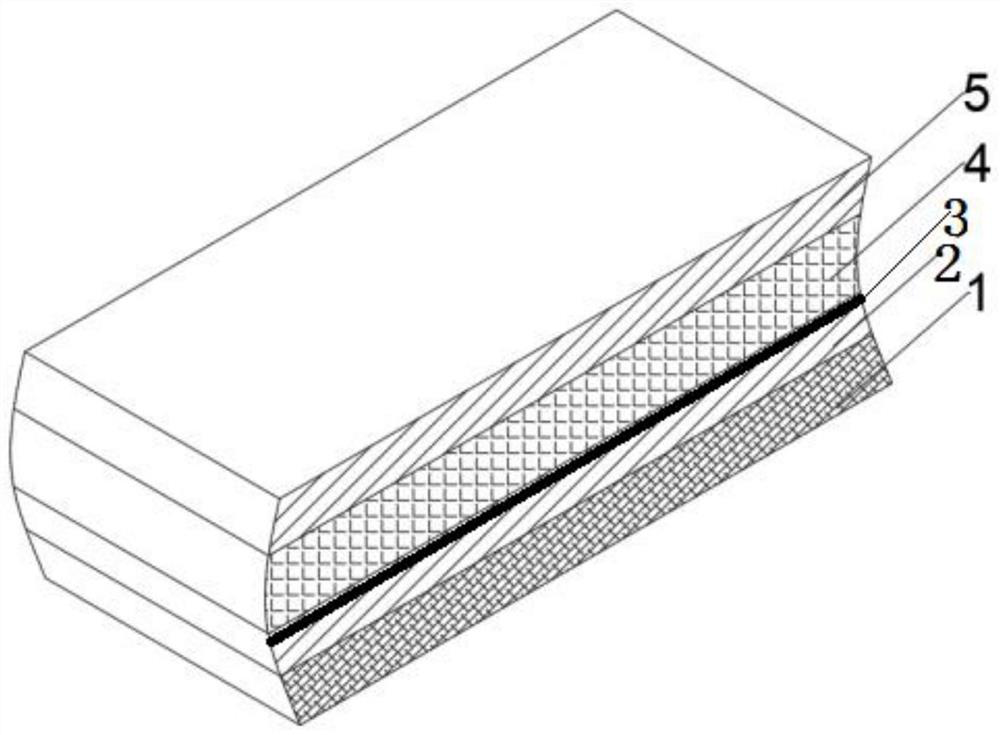

[0029] Such as figure 1 The high-strength seamless floor shown, among them:

[0030] The isolation layer 2 is made of waterproof primer, polyester acrylate and curing agent in a mass ratio of 6:3:0.7. The waterproof primer is the kitchen and bathroom waterproof paint slurry commonly used in home decoration. The curing agent is the floor sealing curing agent purchased on the market. After mixing and stirring the waterproof primer, polyester acrylate and curing agent at 45 degrees Celsius, use the spraying equipment to spray the mixture obtained above evenly on the surface of the base layer. It is necessary to ensure that the spraying thickness is 0.8mm. After it dries, the isolation layer is formed.

[0031] The composite reinforcement layer 4 is prepared from the following raw materials in mass percentage:

[0032] Urea-formaldehyde resin 40%, polyvinyl chloride 5%, composite powder 10%, functional mixture 20%, dimethyl sebacate 15%, benzyl butyrate 5%, phthalic acid and m...

Embodiment 2

[0036] Such as figure 1 The high-strength seamless floor shown, among them:

[0037] The isolation layer 2 is made of waterproof primer, polyester acrylate and curing agent in a mass ratio of 6:3:0.7. The waterproof primer is the kitchen and bathroom waterproof paint slurry commonly used in home decoration. The curing agent is the floor sealing curing agent purchased on the market. Put the waterproof primer, polyester acrylate, and curing agent under the condition of 60 degrees Celsius to mix and stir evenly, and use the spraying equipment to spray the mixture obtained above evenly on the surface of the base layer. It is necessary to ensure that the spraying thickness is 0.8mm. After it dries, the isolation layer is formed.

[0038] The composite reinforcement layer 4 is prepared from the following raw materials in mass percentage:

[0039] Urea-formaldehyde resin 30%, polyvinyl chloride 5%, composite powder 15%, functional mixture 25%, dimethyl sebacate 15%, benzyl butyra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com