Energy-saving structure integrated assembly type thermal insulation wall

A thermal insulation wall and prefabricated technology, applied in the field of home decoration, can solve the problems of high price, easy damage to thermal insulation effect, drop, etc., to achieve good energy saving effect, reduce noise interference, and improve heat transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

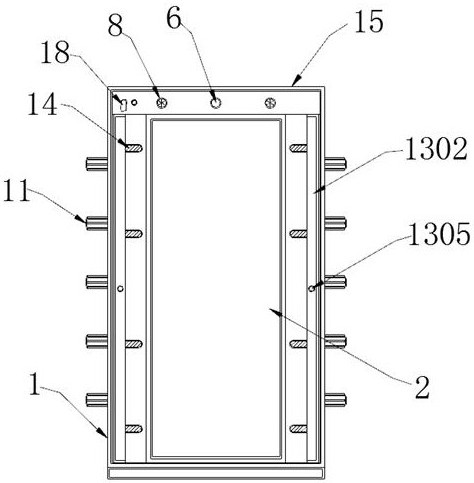

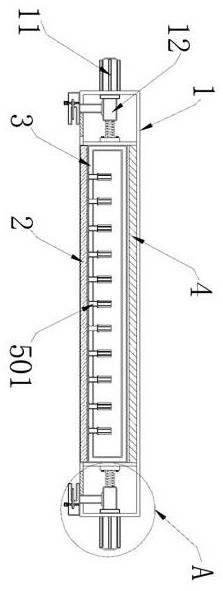

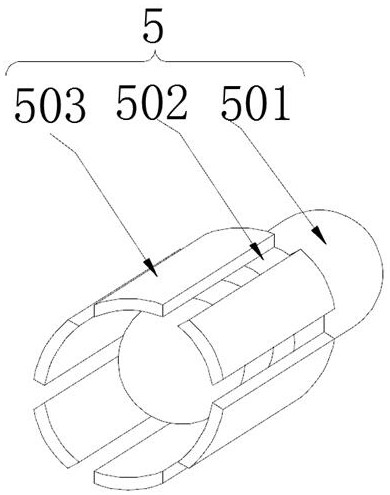

[0031] see Figure 1-8 , the present invention provides a technical solution: an energy-saving structure integrated assembled thermal insulation wall, including a wall 1, a heat storage layer 3 and a displacement assembly 13, a heat conduction layer 2 is arranged on the inner side of the front part of the wall 1, and the heat storage Layer 3 is arranged outside the rear of the heat conduction layer 2, and the sound insulation layer 4 is connected to the outside of the rear of the heat storage layer 3, and the side of the heat conduction layer 2 close to the heat storage layer 3 is provided with a heat conduction component 5, and the top of the heat storage layer 3 The middle end is connected with a water inlet pipe 6, the front end of the water inlet pipe 6 is provided with a sealing cover 7, the top and both sides of the heat storage layer 3 are provided with an exhaust pipe 8, and the inner surface of the exhaust pipe 8 is provided with a valve 9, and the wall 1 There are pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com