Wine brewing raw material treatment process for wine brewing and wine brewing process

A raw material and process technology, applied in the field of brewing technology, can solve the problems of uncontrollable, uncontrollable quality, unstable selenium content in selenium-enriched wine, etc., and achieve the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present invention is a wine brewing raw material treatment process, comprising the following steps:

[0033] Stp1. Mineralize source water into selenium-enriched water with stable selenium concentration required for brewing through mineralized selenium-enriched water treatment equipment;

[0034] Stp2. Wash and drain the raw materials used for brewing, and then add them to the stirring container;

[0035] Boil the selenium-enriched water prepared by Stp1 until it boils, then soak the boiling selenium-enriched water into the brewing raw materials and stir evenly, let it stand for 10-30h; then add the boiling selenium-enriched water into it and continue to stir evenly, and then again Let stand for 10-30h.

[0036] The wine brewing raw material processing technology of the present embodiment 1 can be used for the brewing of rice wine, red wine and beer etc., and it is all carried out by Stp2 when carrying out raw material processing.

Embodiment 2

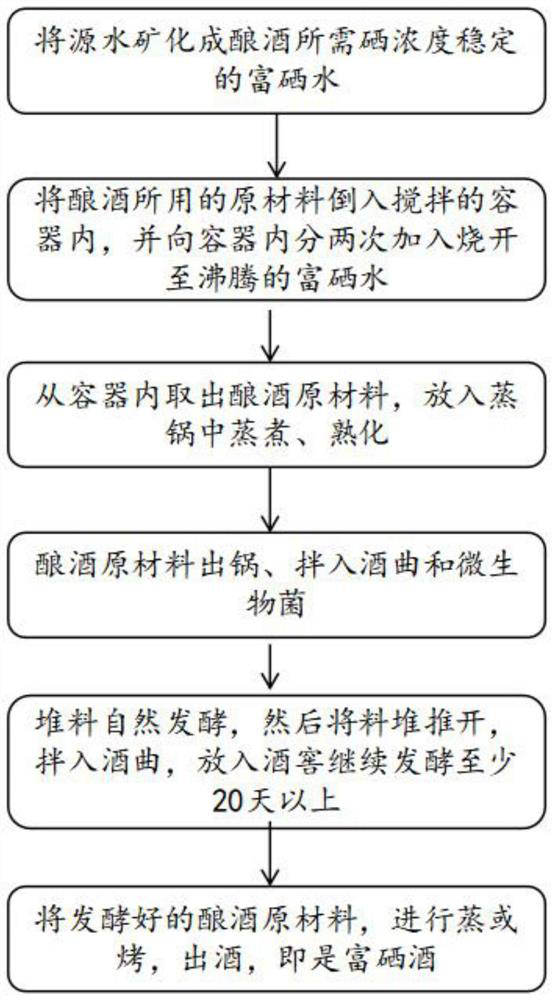

[0038] Such as figure 1 , a brewing process of selenium-enriched wine, comprising the steps of:

[0039] Stp11. Mineralize source water into selenium-enriched water with stable selenium concentration required for brewing through mineralized selenium-enriched water treatment equipment;

[0040] Stp12. Wash and drain the raw materials used for brewing, and then add them to the stirring container;

[0041] Boil the selenium-enriched water prepared by Stp11 until it boils, then soak the boiling selenium-enriched water into the wine-making raw materials and stir evenly, and let it stand for 15 hours; then add the boiling selenium-enriched water to it and continue to stir evenly, and then let stand again 20h;

[0042] Stp13. Take out the brewing raw materials from the container, put them into a steamer for cooking and aging;

[0043] Stp14. The brewing raw materials are taken out of the pot, spread evenly on a dry and flat place, and naturally cooled to 35°C, and then mixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com