Soft soil hardening agent for sea area environment

A technology of hardener and soft soil, applied in the field of soft soil hardener, can solve the problems of cracking and high alkalinity, achieve the effects of low energy consumption, simple production process and reduced engineering economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A kind of softening agent for sea area environment, in parts by mass, comprising:

[0058] 40 parts of cement;

[0059] 8 parts of fly ash;

[0060] 34 parts of slag powder;

[0061] 15 parts of desulfurized gypsum;

[0062] 3 parts admixture.

[0063] Mix the above raw materials in proportion to obtain 1# soft soil hardener.

Embodiment 2

[0065] A kind of softening agent for sea area environment, in parts by mass, comprising:

[0066] 35 parts of cement;

[0067] 9 parts of fly ash;

[0068] 38 parts of slag powder;

[0069] 15 parts of desulfurized gypsum;

[0070] 3 parts admixture.

[0071] Mix the above raw materials in proportion to obtain 2# soft soil hardener.

Embodiment 3

[0073] A kind of softening agent for sea area environment, in parts by mass, comprising:

[0074] 30 parts of cement;

[0075] 10 parts of fly ash;

[0076] 42 parts of slag powder;

[0077] 15 parts of desulfurized gypsum;

[0078] 3 parts energizer.

[0079] Mix the above raw materials in proportion to obtain 3# soft soil hardener.

[0080] Among them, 1# to 3# soft soil hardeners are all mixed materials of powder materials. The specific surface area of slag powder is 450m 2 / kg. The specific surface area of fly ash is 400m 2 / kg. The specific surface area of desulfurized gypsum is 350m 2 / kg. The specific surface area of cement powder is 320m 2 / kg.

[0081] Blank control sample: P.C.42.5 cement.

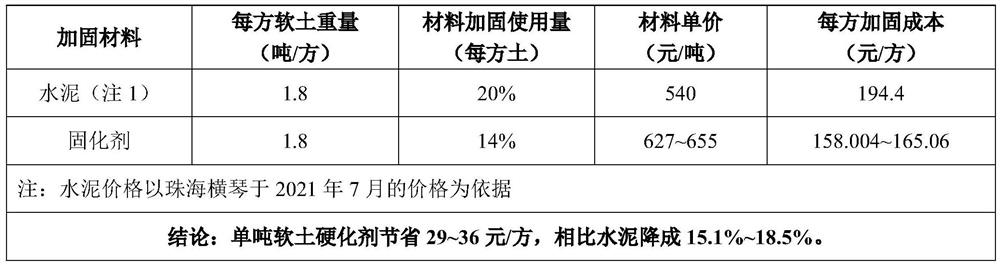

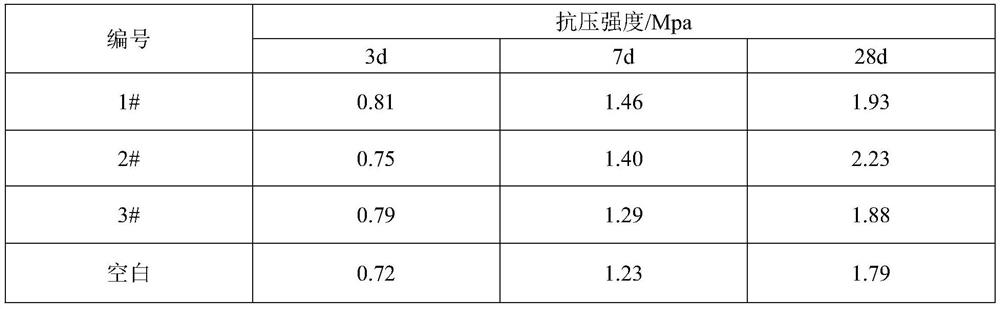

[0082]In the blank group, according to the ratio of cement and soft soil mass 1:4, the products of Examples 1-4 are mixed with water at the ratio of cementitious material and soft soil mass 1:7 to fill the filler with a concentration of 65%, and its compressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com