Reverse osmosis membrane treatment equipment and process for landfill leachate

A landfill leachate and reverse osmosis membrane technology, which is applied in the field of landfill leachate reverse osmosis membrane treatment equipment, can solve the problems of reverse osmosis membrane clogging, incomplete purification of landfill leachate, and consume a lot of time to achieve the effect of speeding up the outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

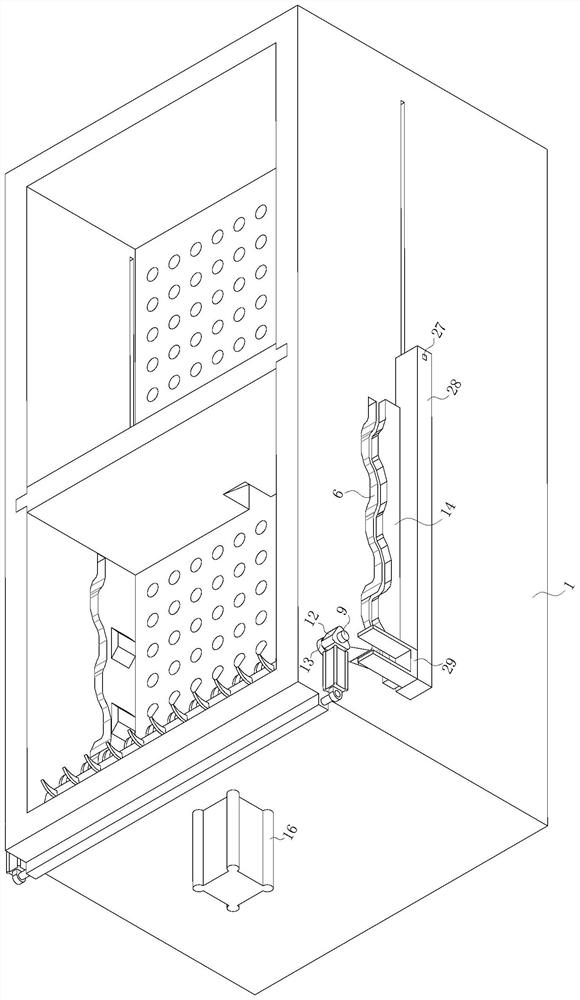

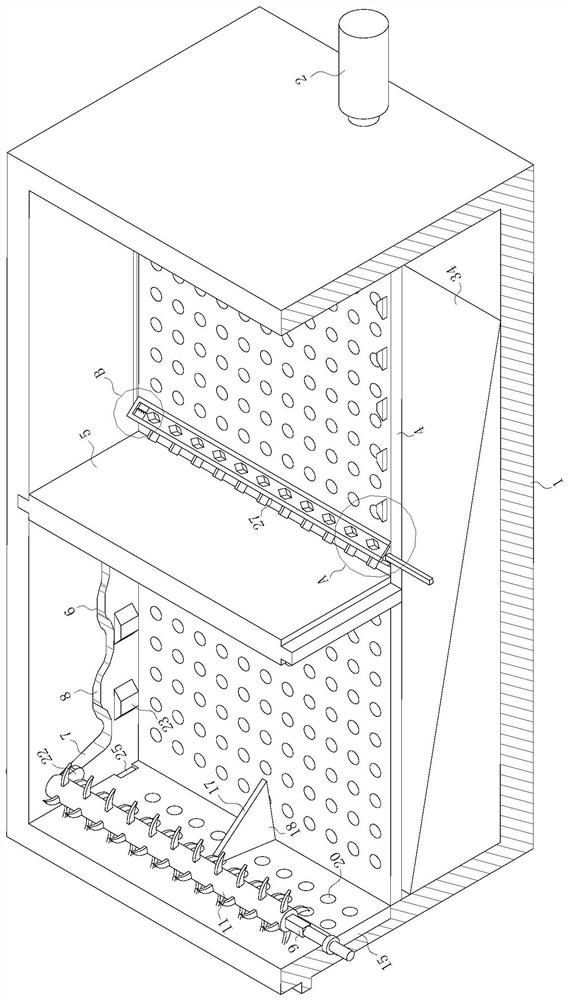

[0034] see Figure 1-9, the present invention provides a technical solution: a landfill leachate reverse osmosis membrane treatment equipment, including a treatment box 1, the right side wall of the treatment box 1 is fixedly connected with a reverse osmosis membrane module 2 communicating with the inside, the treatment box 1 The bottom of the inner wall is provided with a water pump 3 fixedly connected to the left end of the reverse osmosis membrane module 2, the inside of the treatment box 1 is fixedly connected with a sieve plate 4, and the middle position of the top of the sieve plate 4 is provided with a sliding connection in the vertical direction of the inner wall of the front and rear of the treatment box 1. The partition plate 5 on the top, the front and rear side walls of the treatment box 1 are all provided with the first chute 6 located on the left side of the partition plate 5, the first chute 6 includes a chute 7 and a slope groove 8, and the front and rear two ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com