Galvanometer scanning laser welding method based on variable light spots

A galvanometer scanning and laser welding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as limited capacity, and achieve the effect of reducing demand, reducing difficulty, and reducing welding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

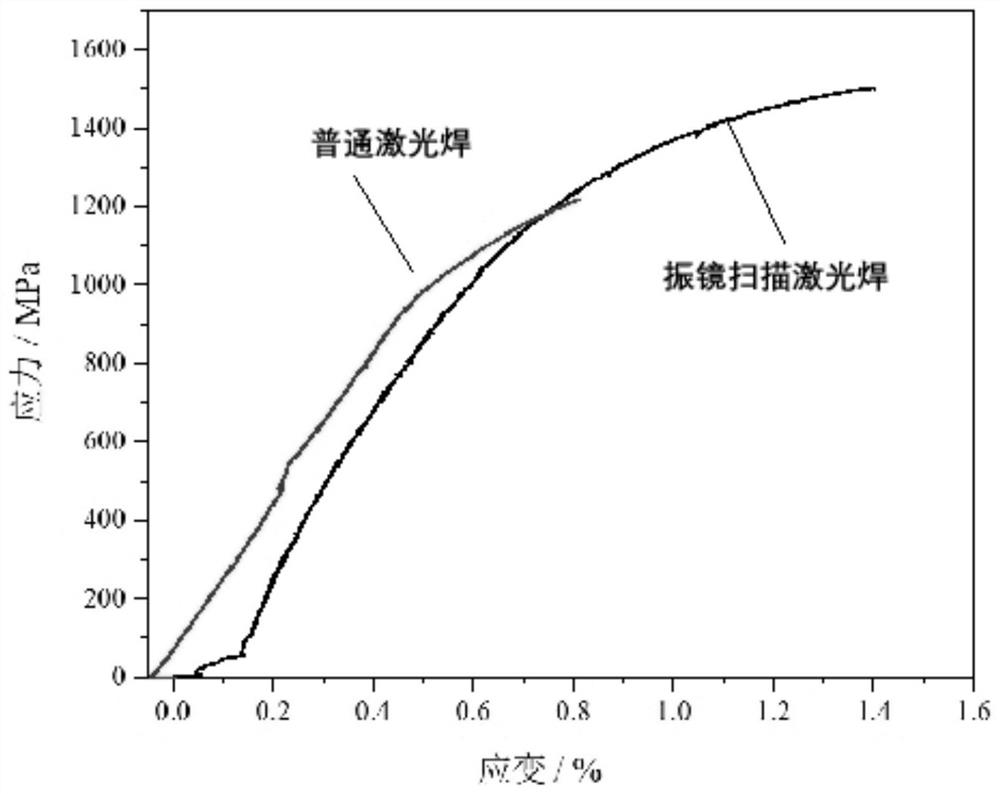

[0065] In this embodiment, the method for laser tailor welding of aluminum-silicon-coated thermoformed steel with variable spot galvanometer scanning includes the following steps:

[0066] Step (1): Select two pieces of aluminum-silicon coating 22MnB5 with a thickness of 1.5 mm, and use alcohol to degrease; the thickness of the coating is 25-35 μm.

[0067] Step (2): Place the two steel plates on the workbench in the form of splicing, and fix them with special welding fixtures to keep them in close contact.

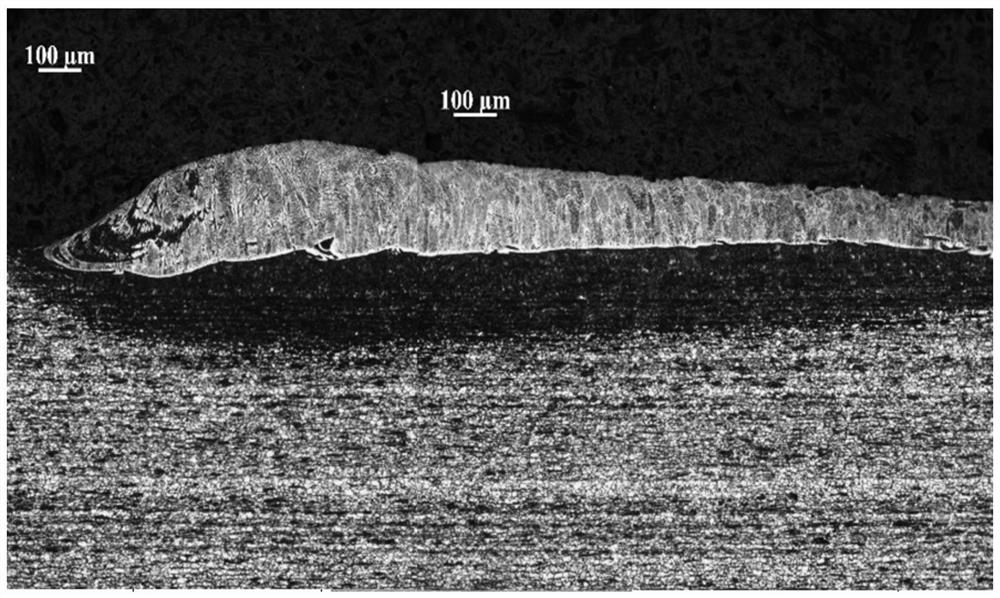

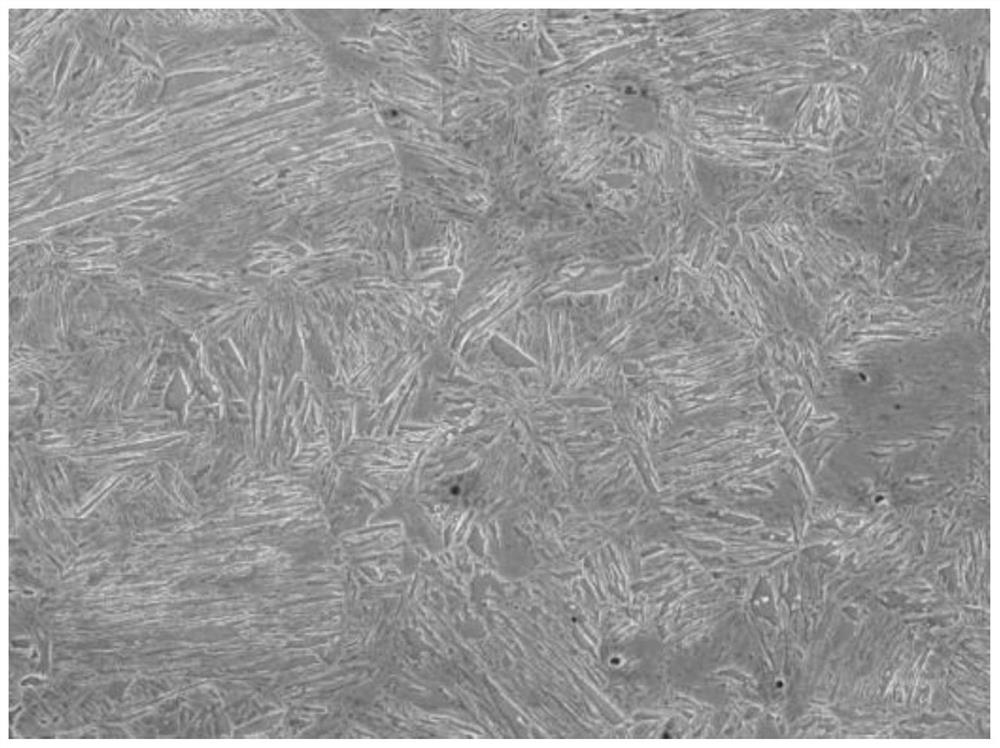

[0068] Step (3): Select the spot size of 2mm, and process the upper surface of the butt weld edge, the laser power is 3kW, the welding speed is 5m / min, the oscillation frequency is 30Hz, there is no shielding gas, and the surface structure is shown in the attached picture figure 1 ;

[0069] Step (4): Select the spot size of 0.7mm, and weld the processed test plate to be welded, the laser power is 2kW, no swing, and the welding speed is 3.5m / min;

[0070] Step (5): The ...

Embodiment 2

[0073] In this embodiment, the aluminum-silicon-coated high-strength hot-formed steel variable spot galvanometer scanning laser patch welding method includes the following steps:

[0074] Step (1): Select high-strength hot-formed steel with aluminum-silicon coating with a thickness of 1.5mm and high-strength hot-formed steel with aluminum-silicon coating with a thickness of 0.8mm, and degrease with alcohol; the thickness of the coating is 25-35 μm;

[0075] Step (2): Place the two steel plates on the workbench in an overlapping manner, and fix them with a special welding fixture to keep the overlapping gap at zero;

[0076] Step (3): Select the spot size to be 1mm, and perform initial welding on the welding area on the surface of the lap welding plate, with laser power of 3kW, swing amplitude of 0.5mm, swing frequency of 50Hz, welding speed of 6m / min, and no shielding gas. The depth of penetration is controlled to just reach the lower surface, and at this time, the upper surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com