Ore crusher for ferrous metal smelting

A technology of ferrous metal, pulverizer, applied in the direction of grain processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

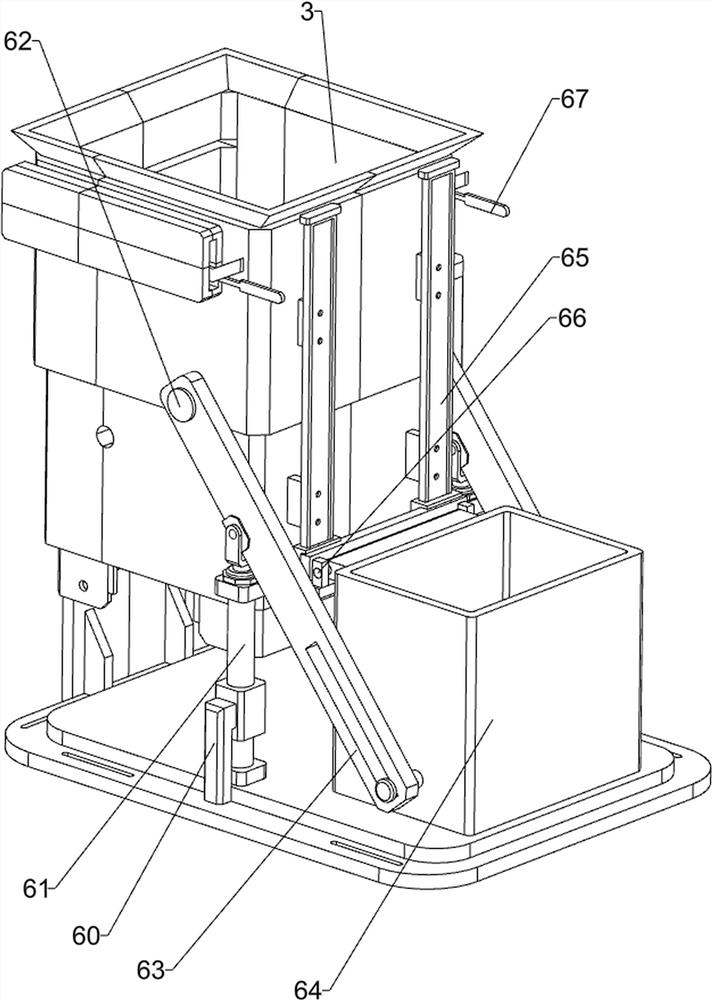

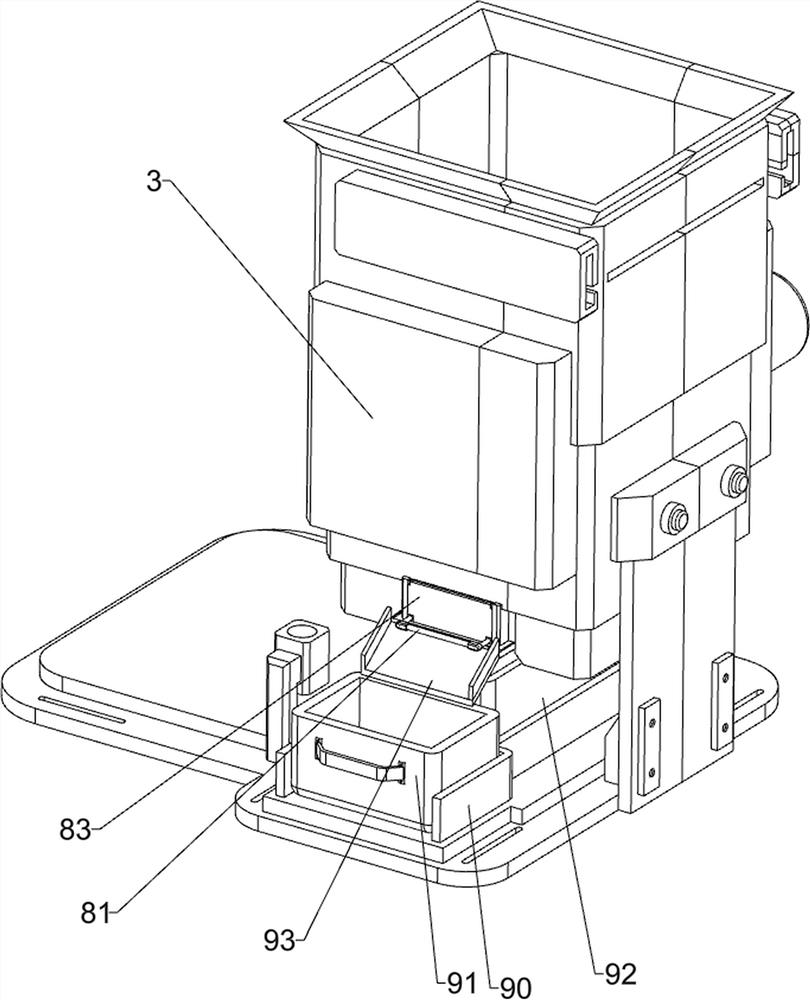

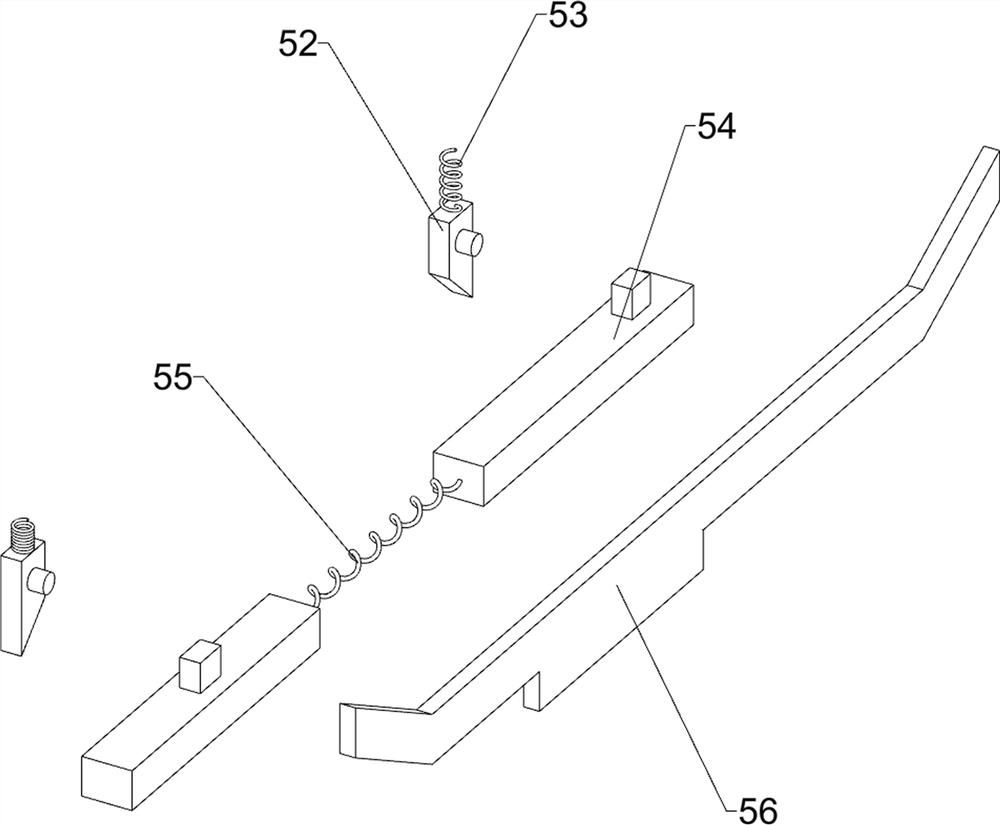

[0031] A kind of ore crusher for ferrous metal smelting, such as Figure 1-Figure 7 As shown, it includes a base plate 1, a support block 2, a housing 3, a crushing mechanism 4, a material blocking mechanism 5 and a feeding mechanism 6, a support block 2 is provided on the left side of the top of the base plate 1, and a housing is provided on the upper side of the support block 2. 3. A crushing mechanism 4 is provided inside the housing 3 , a material blocking mechanism 5 is provided on the upper side of the housing 3 , and a feeding mechanism 6 is provided on the right side of the top of the bottom plate 1 , and the feeding mechanism 6 is connected to the housing 3 .

[0032] The crushing mechanism 4 includes a servo motor 40, a rotating shaft 41, a rotating roller 42 and a gear 43. The front side of the housing 3 is provided with a servo motor 40, and the left and right symmetrical rotation of the lower side of the housing 3 is provided with a rotating shaft 41. The rotating...

Embodiment 2

[0038] On the basis of Example 1, such as Figure 8-Figure 11 As shown, the screening assembly 7 is also included, and the screening assembly 7 includes a loading plate 70, a third spring 71, a screen cloth 72, a ball 73, a fourth spring 74, a pulley 75, a belt 76, a transmission shaft 77 and a cam 78 , the inner lower side of the housing 3 is slidingly provided with a loading plate 70, a third spring 71 is symmetrically arranged on the left and right sides between the loading plate 70 and the housing 3, and a screen 72 is slidingly provided on the loading plate 70, There are grooves symmetrically on the screen 72, and balls 73 are arranged symmetrically on the front side of the top of the loading plate 70. The balls 73 cooperate with the grooves on the screen 72. Between the balls 73 and loading plate 70 The 4th spring 74, housing 3 bottoms left front side rotary transmission shaft 77, are all provided with belt pulley 75 on transmission shaft 77 and left side rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com