Plastic bottle production device for food processing

A production device and food processing technology, applied in applications, household appliances, household components, etc., can solve problems such as time-consuming, laborious blowing, unstable bottle blowing, and low efficiency, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

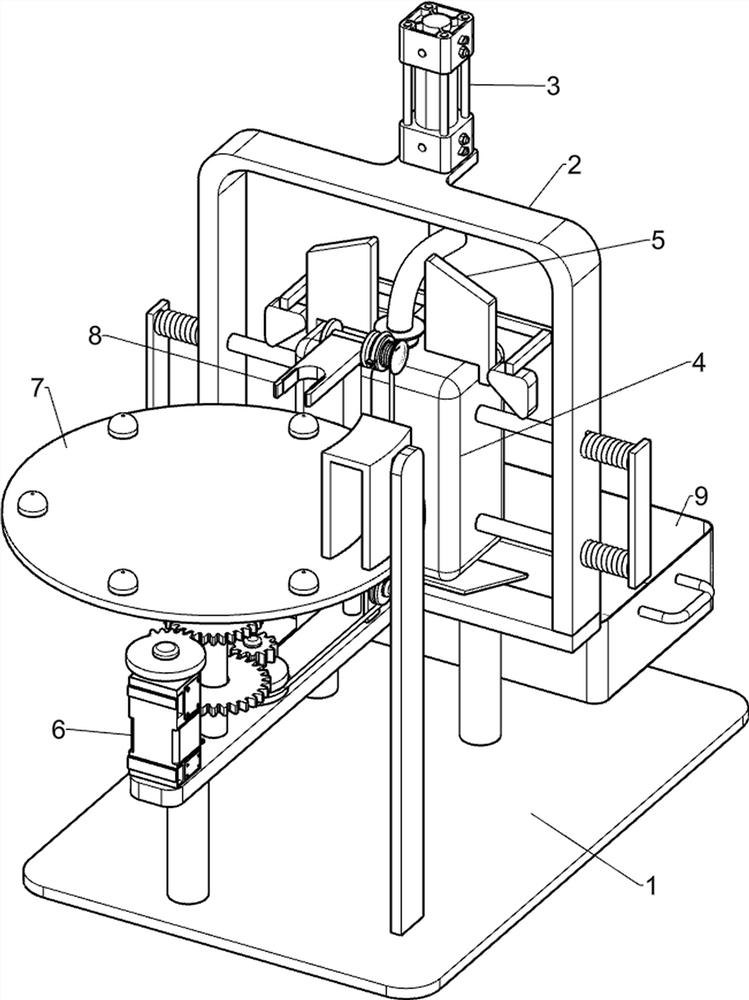

[0070] A plastic bottle production device for food processing, such as figure 1 , figure 2 and image 3 As shown, it includes a base plate 1, a first support frame 2, a cylinder 3 and a blow molding assembly 4, the base plate 1 is provided with a first support frame 2, the rear side of the top of the first support frame 2 is provided with a cylinder 3, and the first support frame 2 is provided with a blow molding assembly 4, and the blow molding assembly 4 is connected with the cylinder 3.

[0071] The blow molding assembly 4 includes a first L-shaped connecting rod 41, an air nozzle 42, a hose 43, a guide rod 44 and a mold 45. The bottom of the cylinder 3 is provided with a first L-shaped connecting rod 41, and the front of the first L-shaped connecting rod 41 The lower part of the side is provided with an air nozzle 42, and the top of the air nozzle 42 is provided with a hose 43, and the left and right sides of the first support frame 2 are slidingly provided with a guide...

Embodiment 2

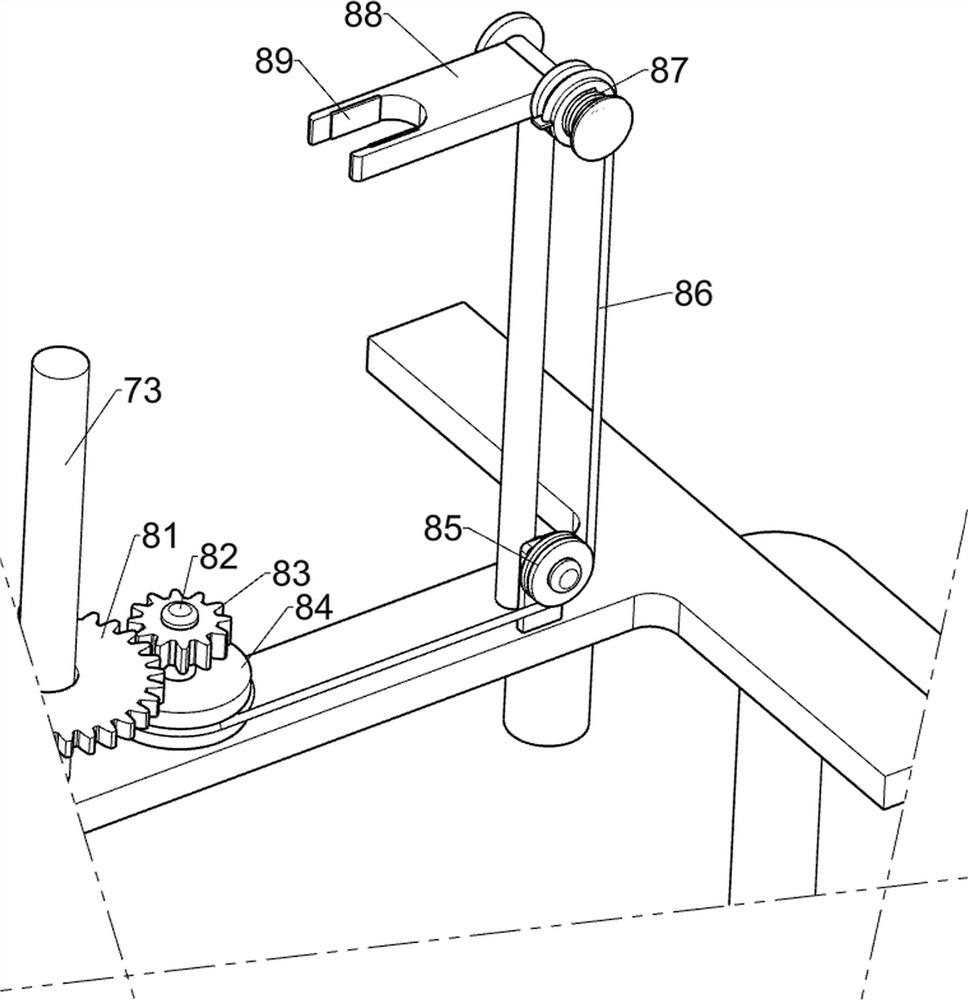

[0075] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, an automatic opening and closing assembly 5 is also included, and the mold 45 is provided with an automatic opening and closing assembly 5. The automatic opening and closing assembly 5 is connected with the first support frame 2, the guide rod 44 and the first L-shaped connecting rod 41, and the automatic opening and closing assembly 5 is connected with the first L-shaped connecting rod 41. The combination assembly 5 includes a compression spring 51, a first wedge-shaped block 52, a second L-shaped connecting rod 53, and a second wedge-shaped block 54. Two compression springs 51 are wound around the guide rods 44 on the left and right sides, and the inside of the compression spring 51 It is connected with the first support frame 2, and the outside of the compression spring 51 is connected with the guide rod 44. The top of the mold 45 on the left and right sides is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com