Ternary composite catalytic material for removing tetracycline in wastewater and preparation method of ternary composite catalytic material

A ternary composite and catalytic material technology, applied in chemical instruments and methods, physical/chemical process catalysts, water pollutants, etc., can solve the problem of high photo-induced electron-hole recombination rate, affecting photocatalytic efficiency, and photocatalytic activity and other problems, to achieve the effect of improving photocatalytic performance, improving photocatalytic performance and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

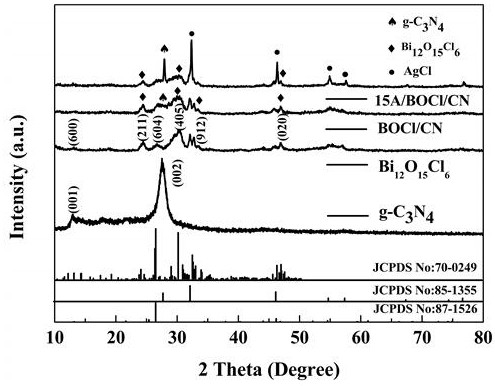

[0037] This embodiment provides a kind of AgCl / Bi 12 o 15 Cl 6 / g -C 3 N 4 Preparation method and application of ternary composite catalytic material:

[0038] (1) g-C 3 N 4 Preparation of:

[0039] Weigh 20 g of urea, place it in an alumina crucible with a cover, heat it to 550 °C in an electric furnace at a rate of 5 °C / min, and keep it for 4 h. Cool to room temperature after the end of the reaction, grind and collect the light yellow powder obtained to obtain g-C 3 N 4 sample;

[0040] (2) Bi 12 o 15 Cl 6 Preparation of:

[0041] Weigh 1 mmol of Bi(NO 3 ) 3 • 5H 2 O, was dissolved into 10 mL of ethylene glycol under vigorous stirring to form a homogeneous solution A. Simultaneously weigh 0.33 mmol of NH 4 Cl, which was dissolved in 35 mL of distilled water to form solution B. Solution A was slowly added to solution B under vigorous stirring, and stirred at room temperature for 1 h. After stirring, it was transferred to an autoclave and heated at 160 °C f...

Embodiment 2

[0056] This embodiment provides a kind of AgCl / Bi 12 o 15 Cl 6 / g -C 3 N 4 Preparation method and application of ternary composite catalytic material:

[0057] (1) g-C 3 N 4 Preparation of:

[0058] Weigh 20 g of urea, place it in an alumina crucible with a cover, heat it to 550 °C in an electric furnace at a rate of 5 °C / min, and keep it for 4 h. Cool to room temperature after the end of the reaction, grind and collect the light yellow powder obtained to obtain g-C 3 N 4 sample;

[0059] (2) Bi 12 o 15 Cl 6 Preparation of:

[0060] Weigh 1 mmol of Bi(NO 3 ) 3 • 5H 2 O, was dissolved into 10 mL of ethylene glycol under vigorous stirring to form a homogeneous solution A. Simultaneously weigh 0.33 mmol of NH 4 Cl, which was dissolved in 35 mL of distilled water to form solution B. Solution A was slowly added to solution B under vigorous stirring, and stirred at room temperature for 1 h. After stirring, it was transferred to an autoclave and heated at 160 °C f...

Embodiment 3

[0070] This embodiment provides a kind of AgCl / Bi 12 o 15 Cl 6 / g -C 3 N 4 Preparation method and application of ternary composite catalytic material:

[0071] (1) g-C 3 N 4 Preparation of:

[0072] Weigh 20 g of urea, place it in an alumina crucible with a cover, heat it to 550 °C in an electric furnace at a rate of 5 °C / min, and keep it for 4 h. Cool to room temperature after the end of the reaction, grind and collect the light yellow powder obtained to obtain g-C 3 N 4 sample;

[0073] (2) Bi 12 o 15 Cl 6 Preparation of:

[0074] Weigh 1 mmol of Bi(NO 3 ) 3 • 5H 2 O, was dissolved into 10 mL of ethylene glycol under vigorous stirring to form a homogeneous solution A. Simultaneously weigh 0.33 mmol of NH 4 Cl, which was dissolved in 35 mL of distilled water to form solution B. Solution A was slowly added to solution B under vigorous stirring, and stirred at room temperature for 1 h. After stirring, it was transferred to an autoclave and heated at 160 °C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com