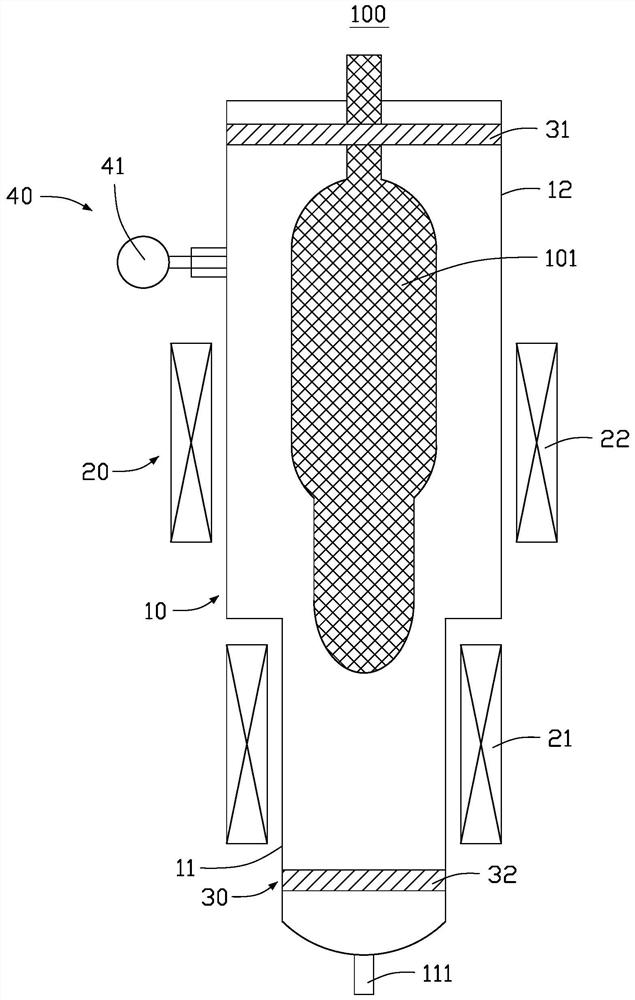

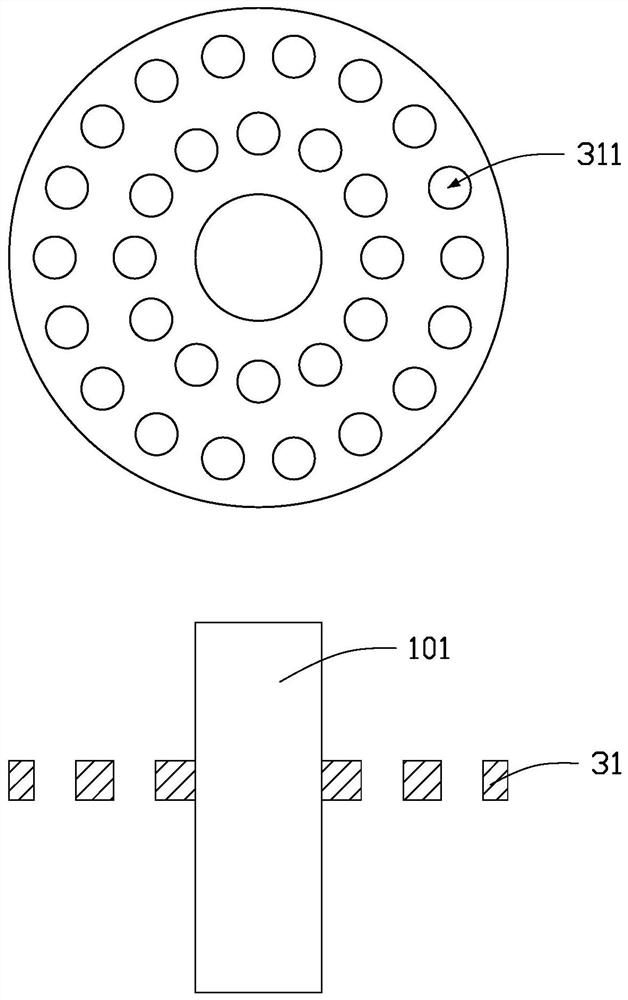

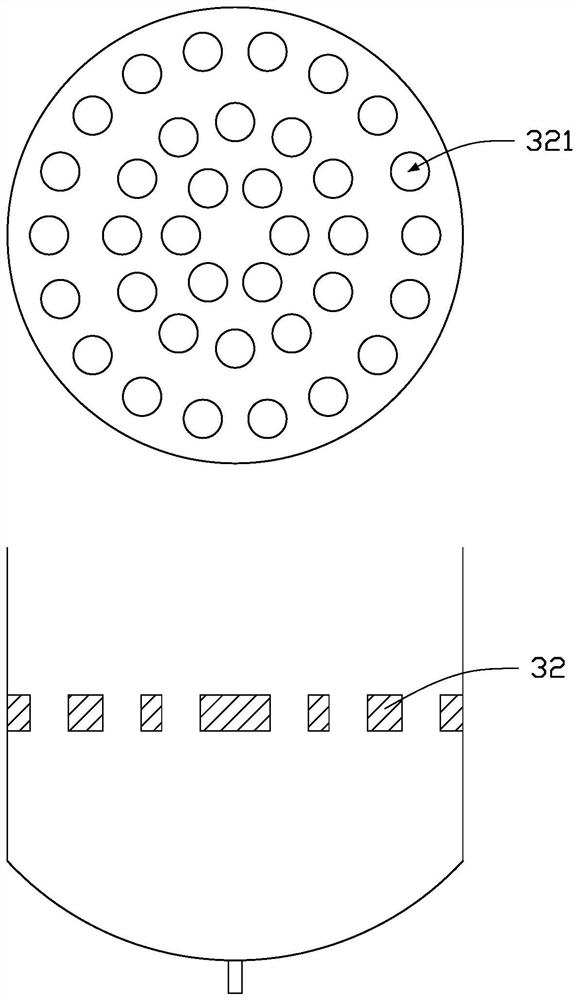

Sintering equipment and sintering method

A sintering equipment and sintering treatment technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of unfavorable radial and axial uniformity of preform rods, pressure fluctuations, etc., to improve axial uniformity, easy to operate, The effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, the technical scheme in the present application embodiment will be described in the present application embodiment, and it is understood that the described embodiments are merely the embodiments of the present application, not all of the embodiments. Based on the embodiments in the present application, one of ordinary skill in the art is in the scope of the present application without making creative labor premistence.

[0031] It should be noted that the component is referred to as "mounting to another component, which can be directly in another component or may also exist. When a component is considered to be "set to" another component, it can be directly set on another component or may exist at the same time.

[0032] All technical and scientific terms used herein are commonly understood by those skilled in the art, unless otherwise defined. The terms used herein in the specification of the present application are merely intended to describe the embodiments of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com