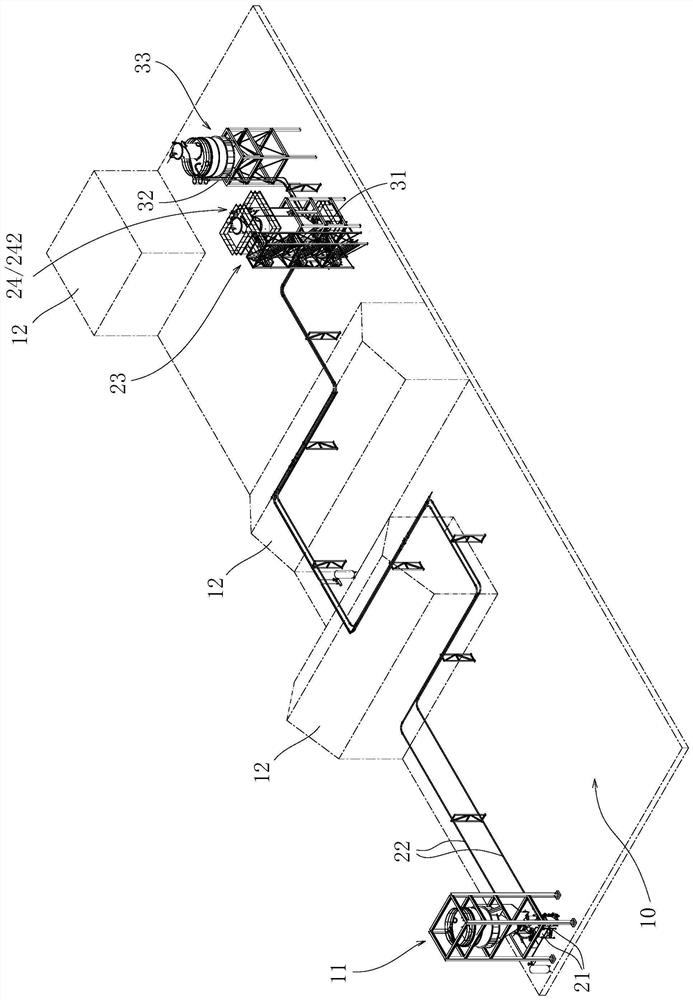

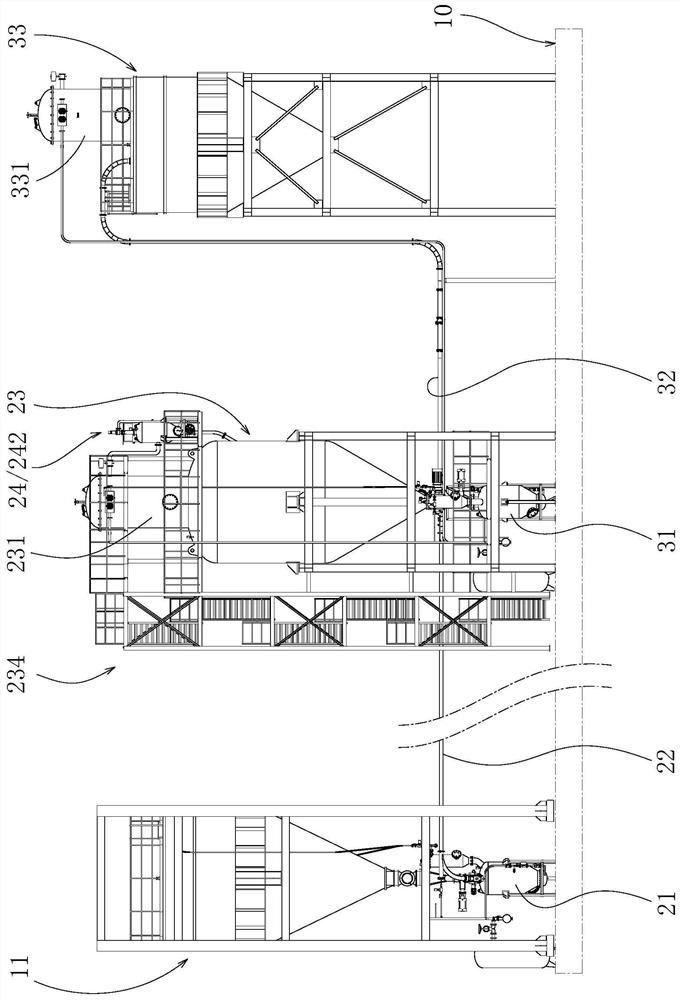

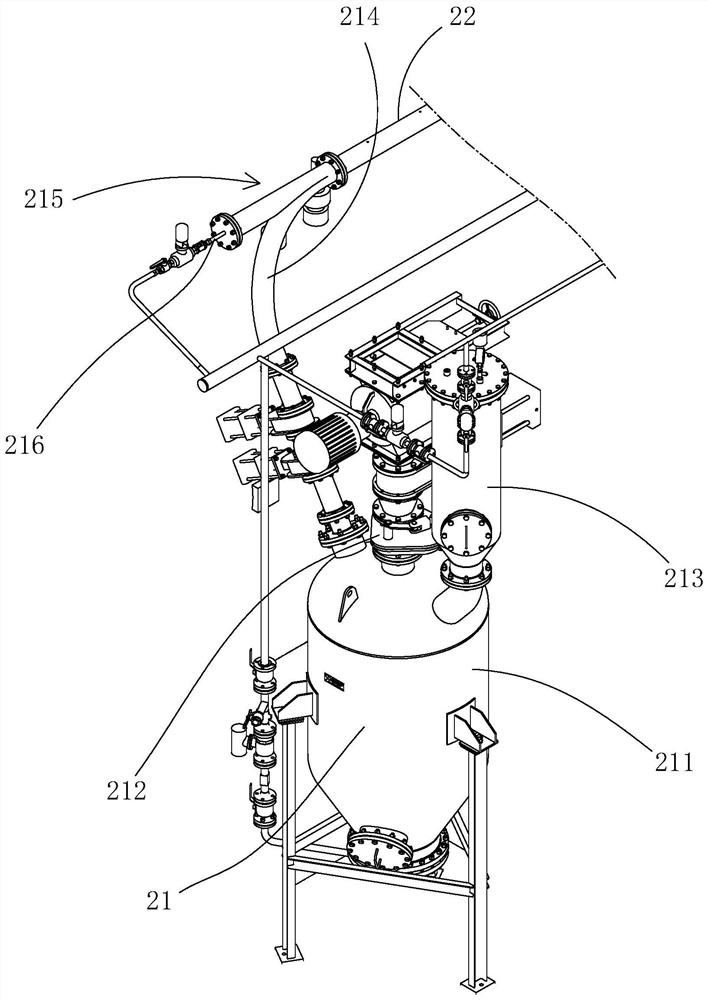

System for pneumatic conveying of particulate matters and gas supply device

A pneumatic conveying and conveying system technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., to achieve the effects of slowing down wear, better controlling the pneumatic conveying of particles, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application approach 1

[0120] Figure 8 It is a schematic structural diagram of a control system of a system for pneumatic conveying of particulate matter according to an embodiment of the present application. The implementation of application scheme 1 can be based on such as Figure 8 control system shown. like Figure 8 As shown, the control system includes a control device 41 and various sensors and actuators connected with the control device 41 by signals.

[0121] like Figure 8 As shown, the control device 41 includes a processor 411 , a memory 412 and a communication interface 415 . The processor 411 and the memory 412 are connected to the communication interface 415, for example, through various interfaces, transmission lines or buses. Optionally, the control device 41 may further include an input device 413 and an output device 414 . Optionally, the control device 41 may adopt a PLC (Programmable Logic Controller) control system.

[0122] The processor 411 may include a central proce...

application approach 2

[0131] In application scheme 2, except that the bulk density of the particulate matter in the silo 11 is less than that of application scheme 1 (the bulk density of the particulate matter in application scheme 2 is 1kg / m 3 ), and the rest of the content is the same as that of application scheme 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com