A Combined Industrial Dust Explosion Simulation Demonstration System

A dust explosion and demonstration system technology, applied in the security field, can solve the problems of inability to reflect the pressure and temperature of dust explosion, inability to visualize the explosion effect, and inability to reflect the movement of dust, etc., to improve portability and disassembly performance, work Stable and reliable performance and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

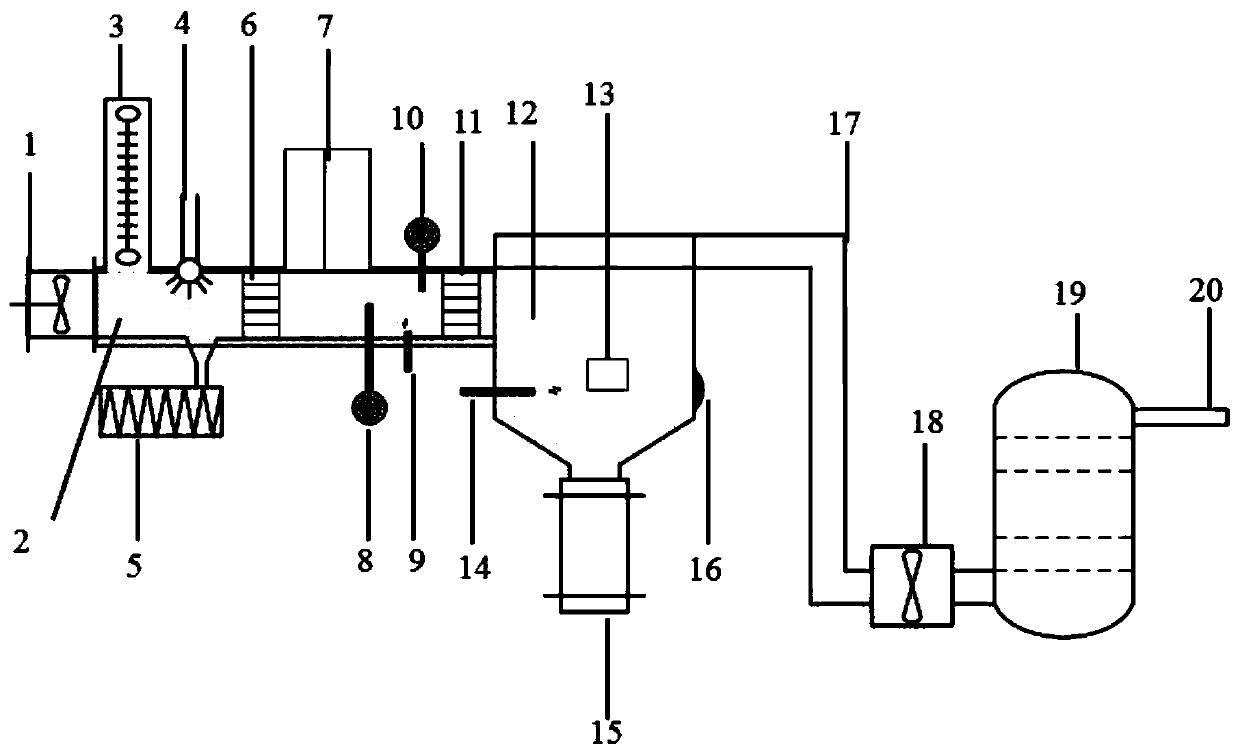

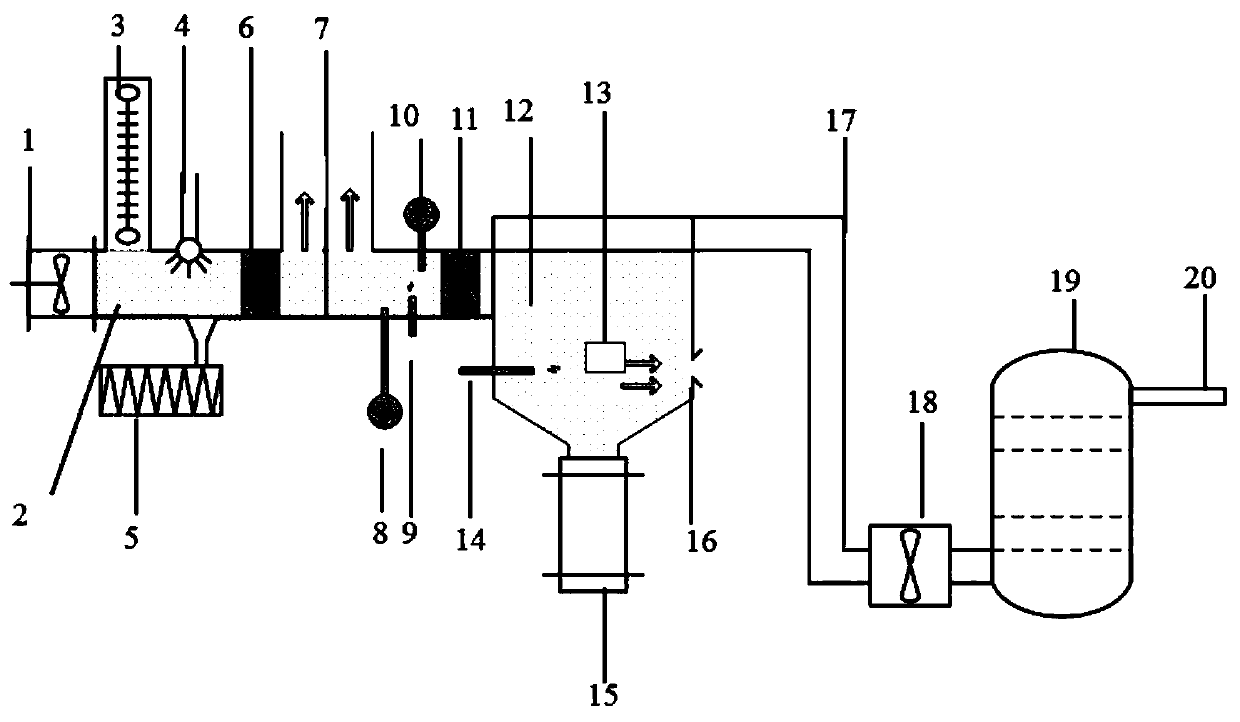

[0031] Such as Figure 1-2 As shown, a combined industrial dust explosion simulation demonstration system includes a dust explosion reaction observation pipe 2, a frequency conversion axial flow fan 1 arranged at one end of the dust explosion reaction observation pipe 2, and is arranged at the other end of the dust explosion reaction observation pipe 2 and connected to the dust explosion reaction observation pipe 2. The dust collector 12 connected to the dust explosion reaction observation pipe 2, the dust conveying unit located between the frequency conversion axial flow fan 1 and the dust collector 12 and connected to the dust explosion reaction observation pipe 2, set in the dust explosion reaction observation pipe 2 The ignition detection control unit on the top, the dust collection box 15 arranged at the bottom of the dust collector 12, the clean air pipeline 17 connected with the top of the dust collector 12, the exhaust gas purifier 19 connected with the clean air pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com