Cage type slag crusher

A slag crusher and cage type technology, which is applied in the field of slag particle refinement equipment, can solve the problems of user intimidation, transportation difficulties, high operating costs, etc., and achieves the effect of reasonable structure, convenient manufacture and use, and pneumatic conveying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] (5) Specific implementation methods, combined with accompanying drawings

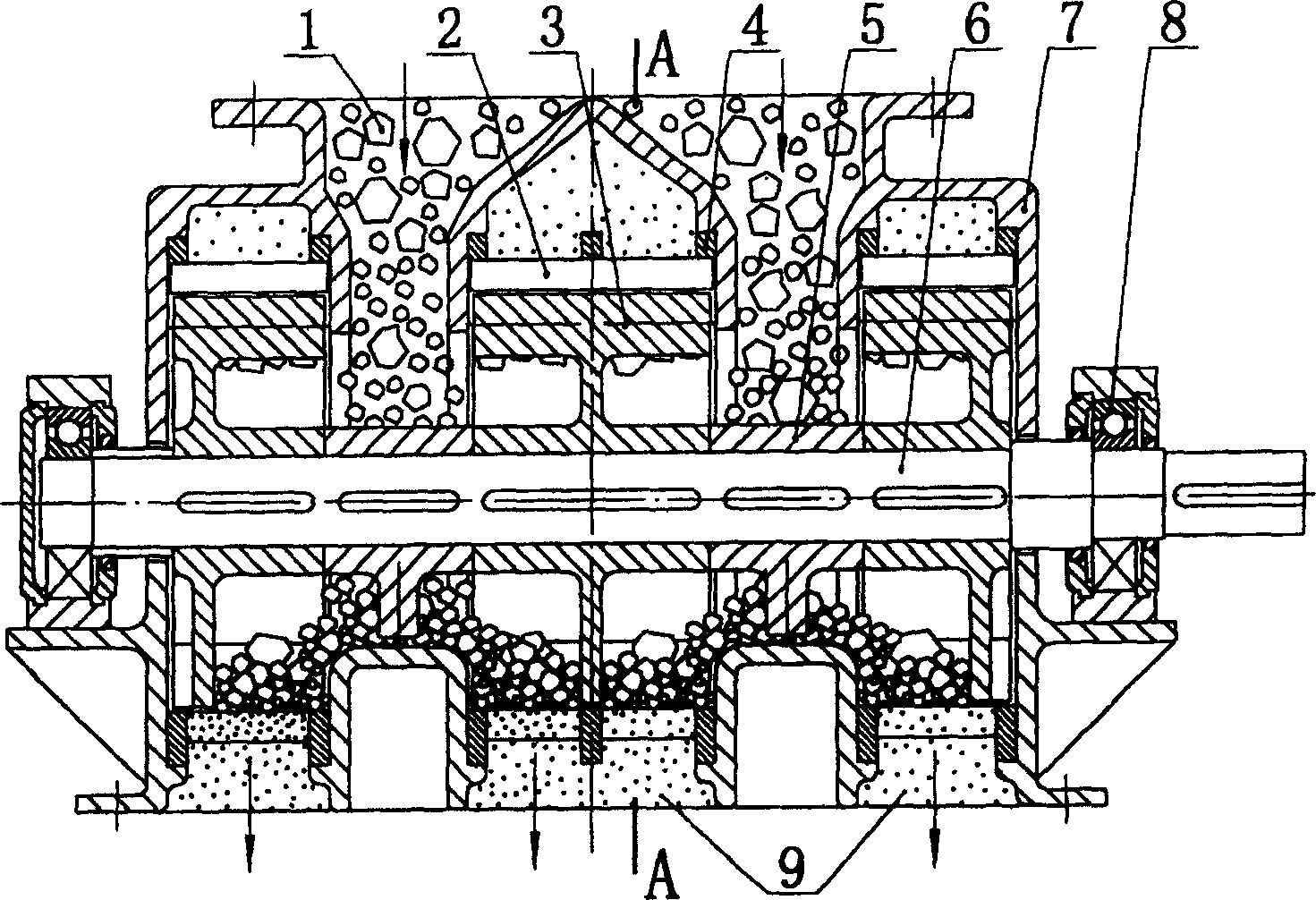

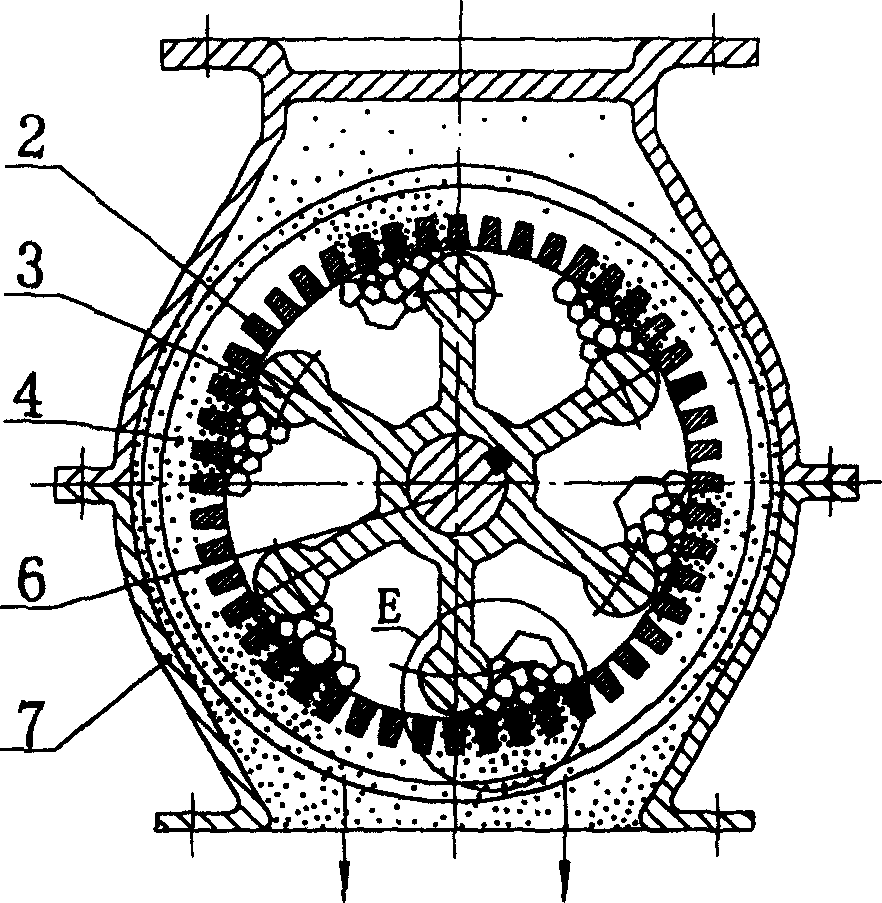

[0017] figure 1 It is a structural schematic diagram of a cage-type slag crusher including 3 sets of impellers and a stator. The cage-type slag crusher includes a housing 7, and a stator composed of an annular skeleton 4 inlaid with grid bars 2 is fixedly installed in the housing 7. The section of the grid bar 2 is trapezoidal. The rotor that can rotate at a high speed is housed in the stator is formed by the impeller 3 sleeved on the main shaft 6 of the slag crusher, and the main shaft of the slag crusher is supported by bearings 8 . The cross section of the impeller 3 is slightly like a chrysanthemum, and the 6 petals are evenly distributed along the circumference, and the ends of the petals are arc-shaped. image 3 As can be seen. There are 3 sets of stators and impellers, and two spacers 5 are arranged between the 3 sets of impellers mounted on the main shaft.

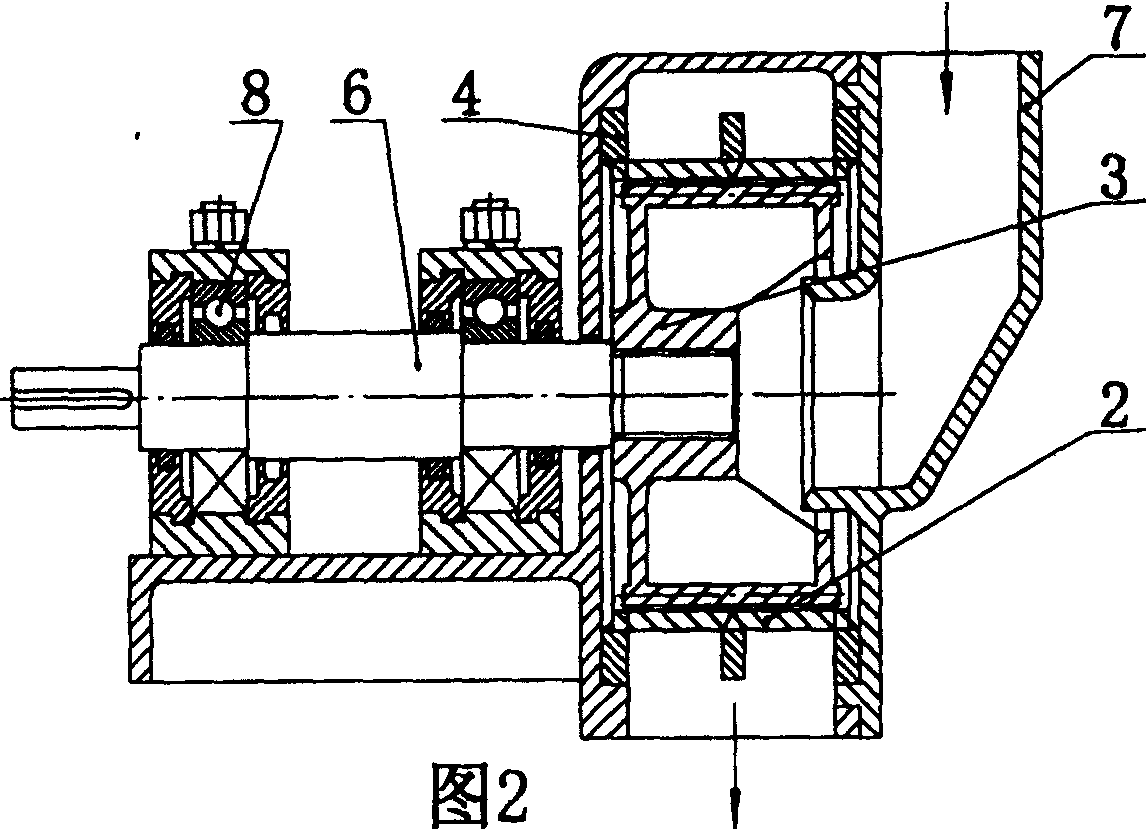

[0018] Fig. 2 shows anothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com