Manufacturing method of kettle

A manufacturing method and spout technology, applied to household containers, etc., can solve problems such as weld damage, vacuum layer failure, and tiny gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A method for making a pot, comprising the steps of:

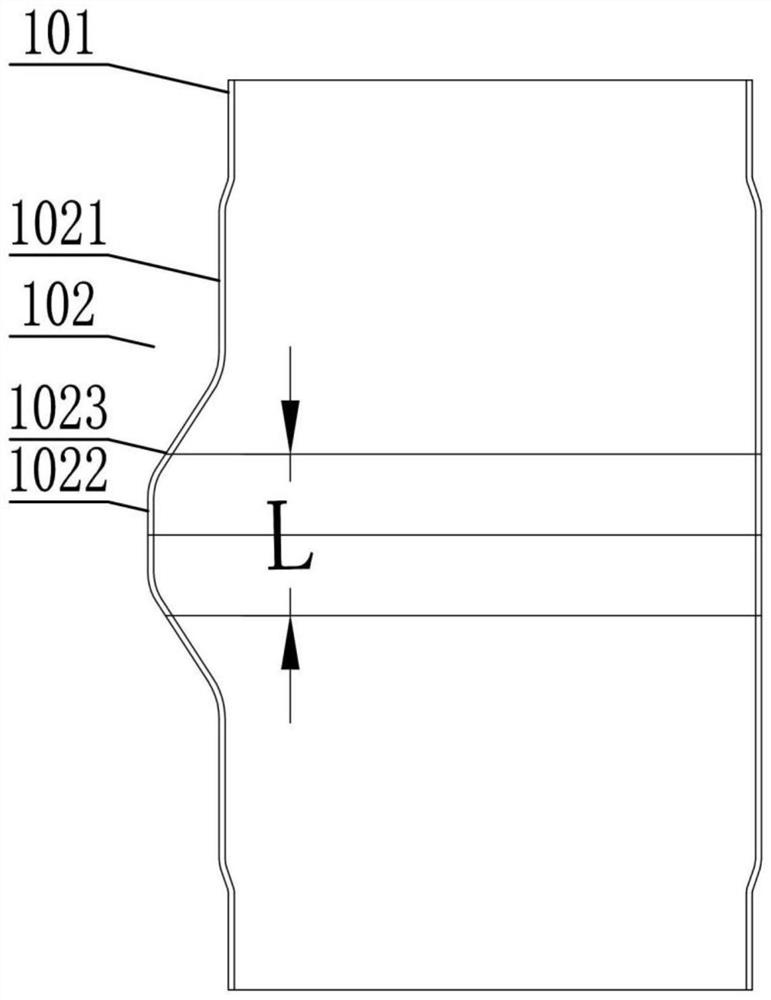

[0062] a. Take a pipe 101 and carry out surface pretreatment. After the surface pretreatment is completed, the pipe 101 is swelled and formed in the middle of the pipe 101 with an outer convex portion 102. The outer convex portion 102 includes a processing area 1021, A margin area 1022, the margin area 1022 is located in the middle of the convex portion 102, the processing area 1021 is located on both sides of the convex portion 102, the thickness of the pipe 101 is 1mm, the margin The length L of the zone 1022 is 22mm;

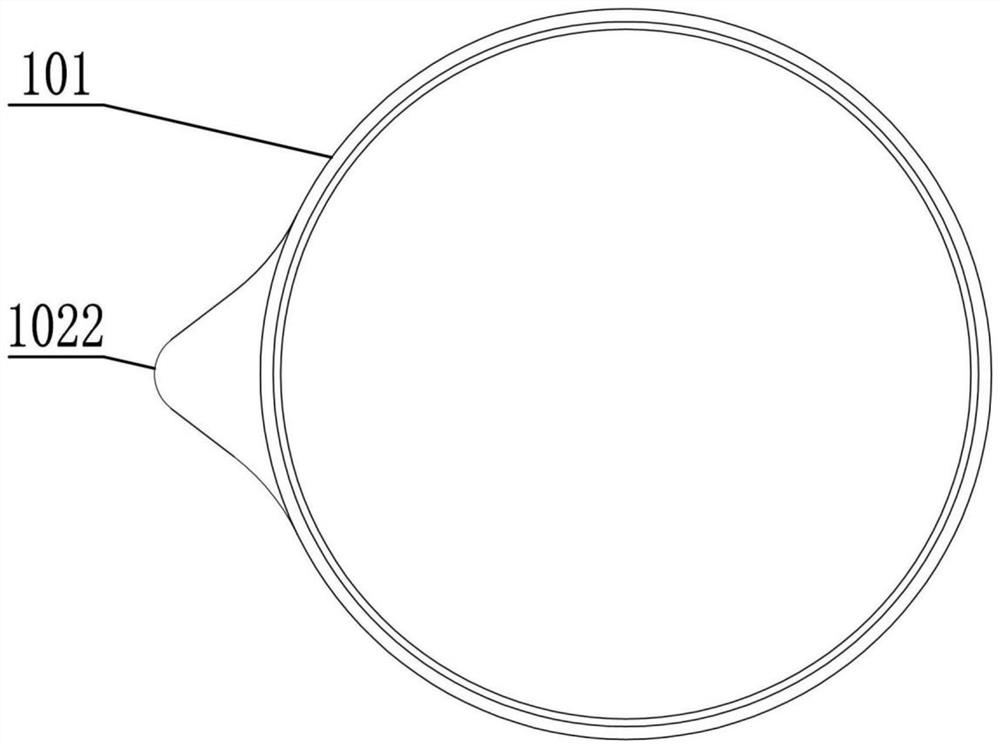

[0063] b. Laser cut the pipe material 101 from the middle of the margin area 1022 to obtain a spout body 103 with a small convex portion 104, and then shape the small convex portion 104 to make the small convex portion 104 Retract toward the direction of the pipe material 101, and then laser cut the small convex portion 104 again, so as to form the spout 105 on the spout body 103;

[0064] c. Cut ...

Embodiment 2

[0074] A method for making a pot, comprising the steps of:

[0075] a. Take a pipe 101 and carry out surface pretreatment. After the surface pretreatment is completed, the pipe 101 is swelled and formed in the middle of the pipe 101 with an outer convex portion 102. The outer convex portion 102 includes a processing area 1021, A margin area 1022, the margin area 1022 is located in the middle of the convex portion 102, the processing area 1021 is located on both sides of the convex portion 102, the thickness of the pipe 101 is 1.5 mm, and the margin The length L of the measuring area 1022 is 30mm;

[0076] b. Laser cut the pipe material 101 from the middle of the margin area 1022 to obtain a spout body 103 with a small convex portion 104, and then shape the small convex portion 104 to make the small convex portion 104 Retract toward the direction of the pipe material 101, and then laser cut the small convex portion 104 again, so as to form the spout 105 on the spout body 103; ...

Embodiment 3

[0087] A method for making a pot, comprising the steps of:

[0088] a. Take a pipe 101 and carry out surface pretreatment. After the surface pretreatment is completed, the pipe 101 is swelled and formed in the middle of the pipe 101 with an outer convex portion 102. The outer convex portion 102 includes a processing area 1021, A margin area 1022, the margin area 1022 is located in the middle of the convex portion 102, the processing area 1021 is located on both sides of the convex portion 102, the thickness of the pipe 101 is 1.2mm, and the excess The length L of the measuring area 1022 is 26mm;

[0089] b. Laser cut the pipe material 101 from the middle of the margin area 1022 to obtain a spout body 103 with a small convex portion 104, and then shape the small convex portion 104 to make the small convex portion 104 Retract toward the direction of the pipe material 101, and then laser cut the small convex portion 104 again, so as to form the spout 105 on the spout body 103; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com