Hydrogen fuel cell tail gas mixing and diluting device and hydrogen fuel cell

A fuel cell and exhaust gas mixing technology, which is applied in the direction of fuel cells, mixers, mixing methods, etc., can solve the problems of uneven gas composition and unguaranteed safety, and achieve hydrogen dilution and uniform mixing with good safety performance , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

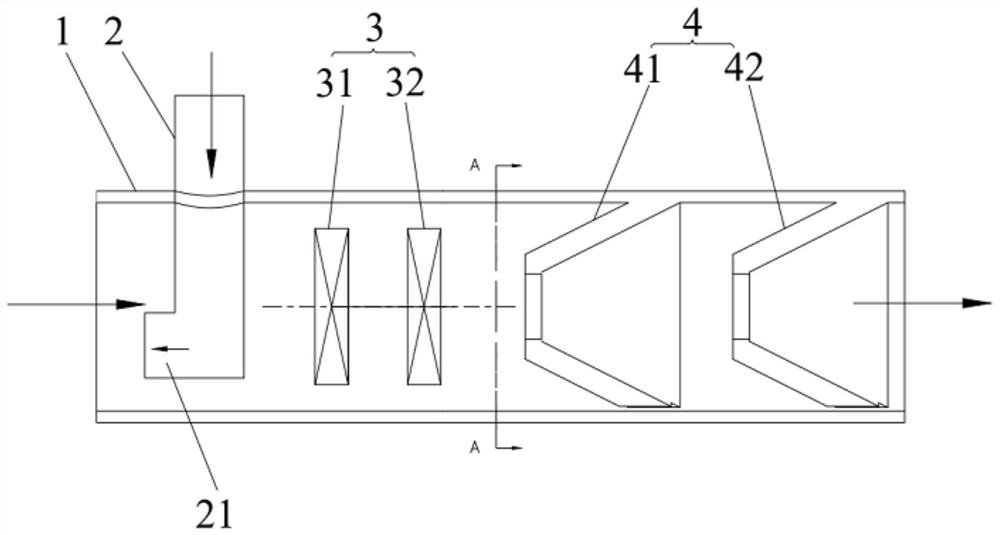

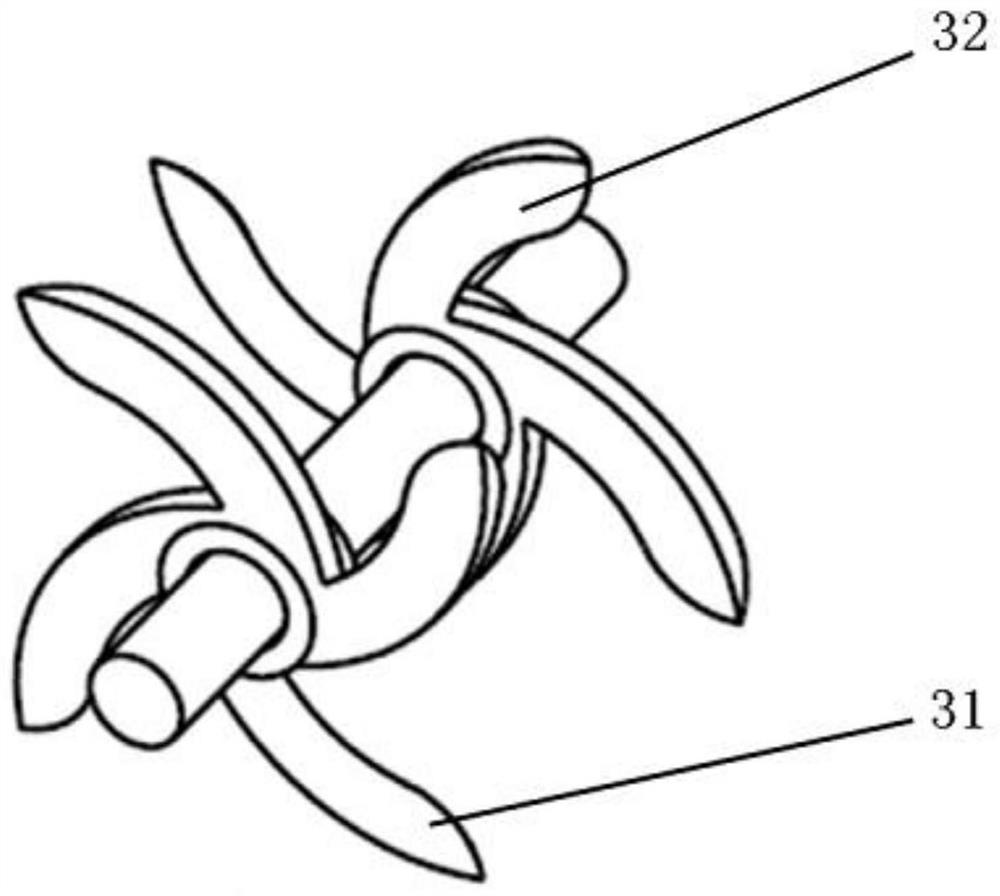

[0038] Hydrogen fuel cells have the advantages of no pollution, high reactant preparation efficiency, and are conducive to improving the NVH performance of automobiles, and have excellent application prospects. However, because the existing hydrogen exhaust system cannot guarantee sufficient dilution of hydrogen, this embodiment provides a hydrogen fuel cell exhaust gas mixing and dilution device to solve this problem.

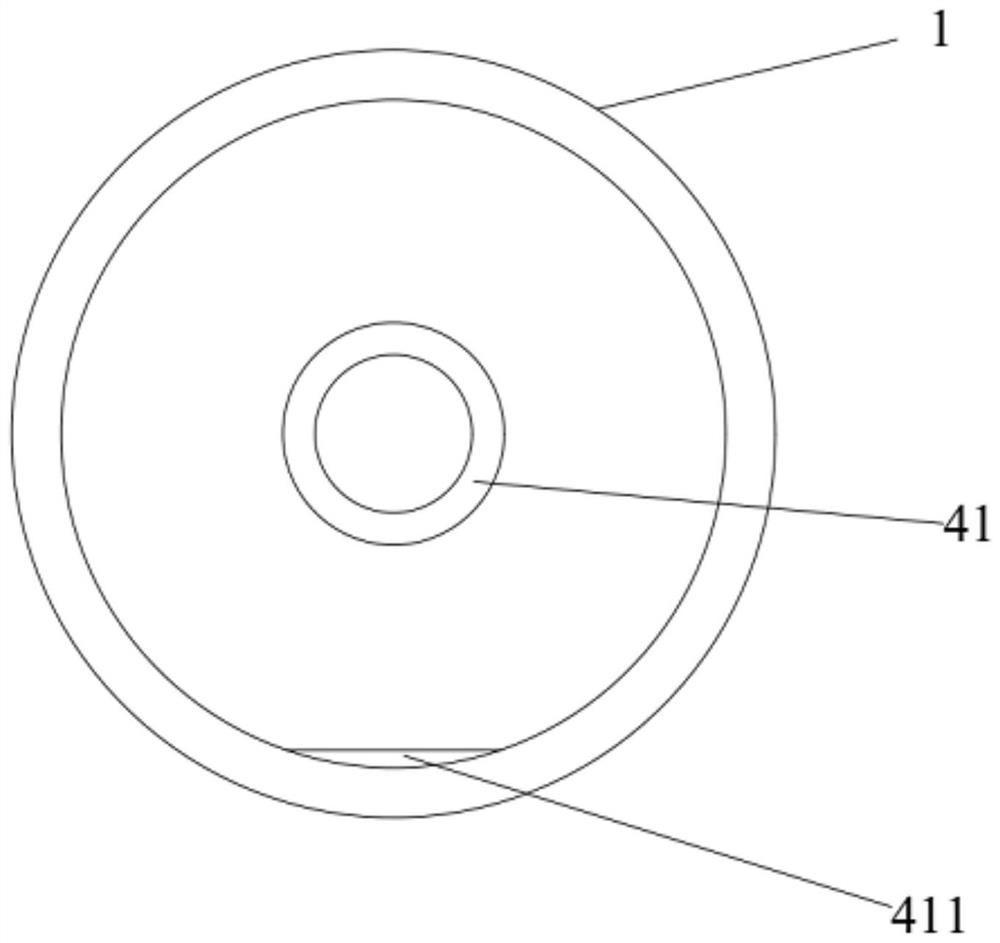

[0039] like figure 1 As shown, the hydrogen fuel cell exhaust gas mixing and dilution device includes a main exhaust pipe 1 and a hydrogen exhaust pipe 2 . After the fuel in the hydrogen fuel cell system undergoes a stack reaction, the tail gas includes hydrogen and air. Wherein, the air is discharged from the main tail pipe 1, and the hydrogen is discharged from the hydrogen tail pipe 2. In the stack reaction, the ratio of hydrogen to oxygen is 2:1, but in order to ensure the utilization rate of hydrogen, an oversupply of air is adopted in the actual supply...

Embodiment 2

[0048] This embodiment provides a hydrogen fuel cell, including the hydrogen fuel cell tail gas mixing and dilution device in Embodiment 1. The hydrogen fuel cell is equipped with the hydrogen fuel cell tail gas mixing and dilution device in the first embodiment, which can realize the dilution and uniform mixing of the tail gas hydrogen, so as to have good safety performance.

[0049] Specifically, the hydrogen fuel cell exhaust gas mixing and dilution device is installed obliquely in the hydrogen fuel cell, and it is necessary to ensure that the value range of the angle α between the main exhaust pipe 1 and the horizontal plane is 5°<α≤90°, that is, for To ensure that the condensed water is discharged in time, α needs to be greater than 5°. The upstream of the main tailpipe 1 and the hydrogen tailpipe 2 in the hydrogen fuel cell tail gas mixing and dilution device are connected to the stack reactor, and the fuel of the hydrogen fuel cell is hydrogen after the stack reaction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com