Method for producing grain-oriented electromagnetic steel sheet

A manufacturing method, the technology of electromagnetic steel plate, applied in the direction of manufacturing tools, circuits, magnetic objects, etc., to achieve the effect of excellent magnetic properties, large effect, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

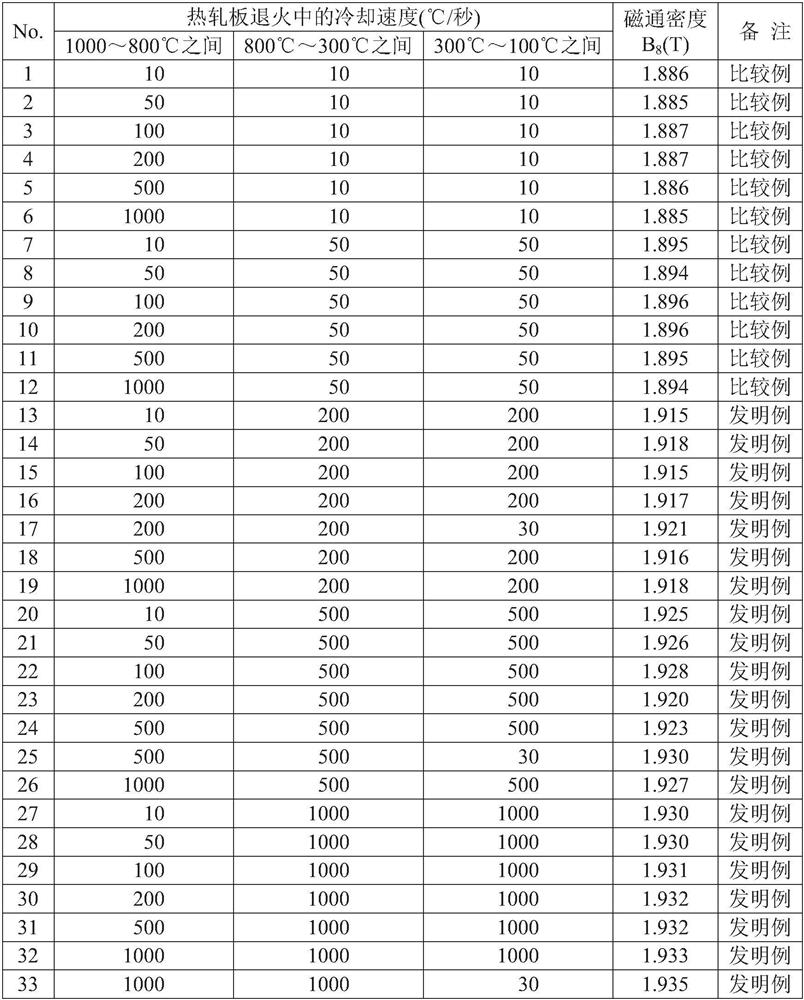

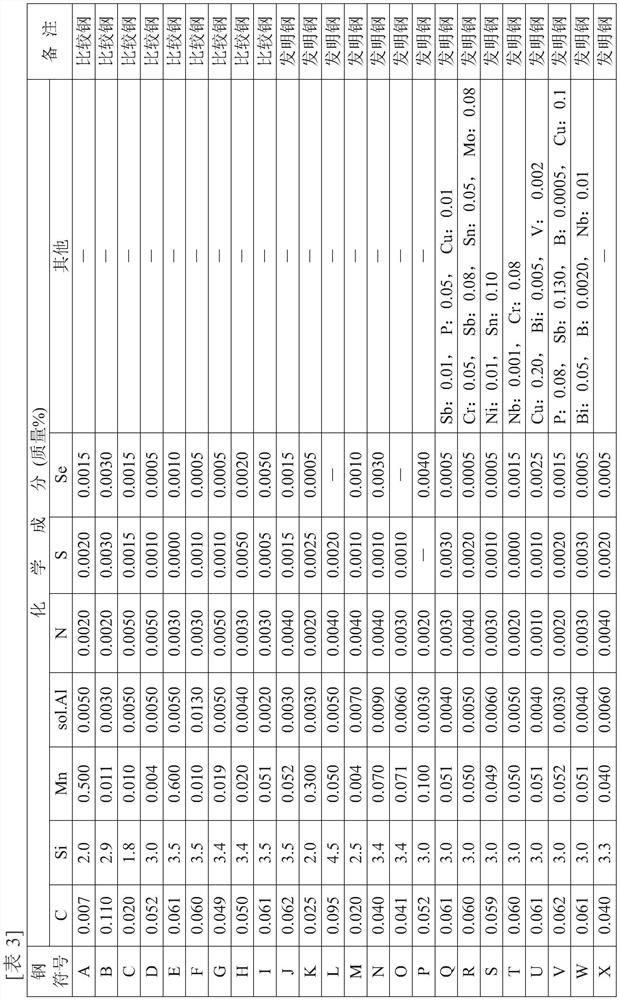

[0068] A slab having the composition shown in Table 3, with the remainder consisting of Fe and unavoidable impurities was produced by continuous casting, heated to a temperature of 1280°C, and then hot-rolled to obtain a hot-rolled sheet with a thickness of 2.2 mm. , the hot-rolled sheet was annealed at 1050° C. for 20 seconds. At this time, the average cooling rate between 800°C and 300°C and between 300°C and 100°C in the cooling process of annealing the hot-rolled sheet was changed as shown in Table 4. Then, after cold rolling into a cold-rolled sheet with a final plate thickness of 0.23 mm, in 60 volume %H 2 -40vol%N 2 In addition, primary recrystallization annealing also serving as decarburization annealing was performed at 830° C. for 150 seconds in a humid atmosphere with a dew point of 55° C. At this time, the average temperature increase rate between 500° C. and 700° C. during the heating process was set to 200° C. / sec.

[0069] Then, after the above-mentioned prim...

Embodiment 2

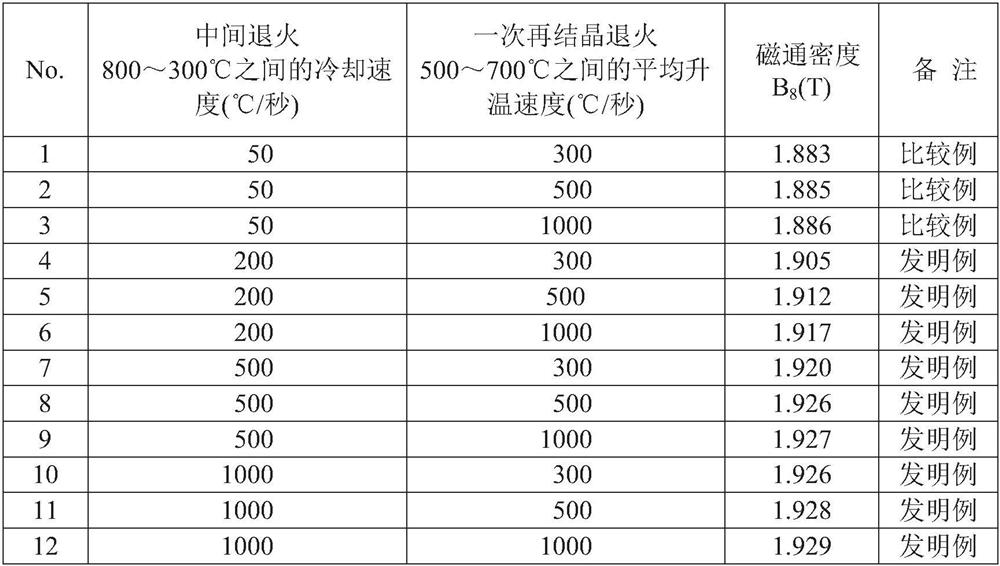

[0075] Contains C: 0.049% by mass, Si: 3.5% by mass, Mn: 0.069% by mass, sol.Al: 0.0070% by mass, N: 0.0035% by mass, and S: 0.0010% by mass, with the balance consisting of Fe and The steel slab made of avoided impurities was reheated to a temperature of 1230° C., and then hot-rolled to form a hot-rolled sheet with a thickness of 2.0 mm. The hot-rolled sheet was subjected to hot-rolled sheet annealing at 950° C.×20 seconds. Then, the intermediate sheet thickness was adjusted to 1.3 mm by the first cold rolling, and intermediate annealing was performed at 1060° C. for 60 seconds, and then the second cold rolling was performed to obtain a cold-rolled sheet having a final sheet thickness of 0.20 mm. At this time, the average cooling rate between 800°C and 300°C and between 300°C and 100°C in the cooling process of the hot-rolled sheet annealing and intermediate annealing was changed as shown in Table 5. Next, at 55 vol% H 2 -45vol%N 2 In addition, primary recrystallization anne...

Embodiment 3

[0081] In the same manner as in Example 2, a continuous casting method containing C: 0.049% by mass, Si: 3.5% by mass, Mn: 0.069% by mass, sol.Al: 0.0070% by mass, N: 0.0035% by mass and S: 0.0010% by mass , the balance of which is composed of Fe and unavoidable impurities is heated to a temperature of 1280°C, and then hot-rolled to form a hot-rolled sheet with a thickness of 2.5 mm. The hot-rolled sheet is subjected to 1,000°C×60 seconds Annealing of hot-rolled sheets. At this time, the average cooling rate between 800°C and 300°C and between 300°C and 100°C in the cooling process of annealing the hot-rolled sheet was changed as shown in Table 6. Then, the intermediate sheet thickness was adjusted to 1.8 mm by the first cold rolling, and intermediate annealing was performed at 1080° C. for 60 seconds, and then the cold rolled sheet having a final sheet thickness of 0.23 mm was produced by the second cold rolling. At this time, the average cooling rate between 800° C. and 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com