A kind of semiconductor growth equipment and working method thereof

A semiconductor and equipment technology, applied in the field of semiconductor growth equipment, can solve the problems of high optimal growth temperature range and narrow use range, and achieve the effect of reducing the growth temperature range and expanding the use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

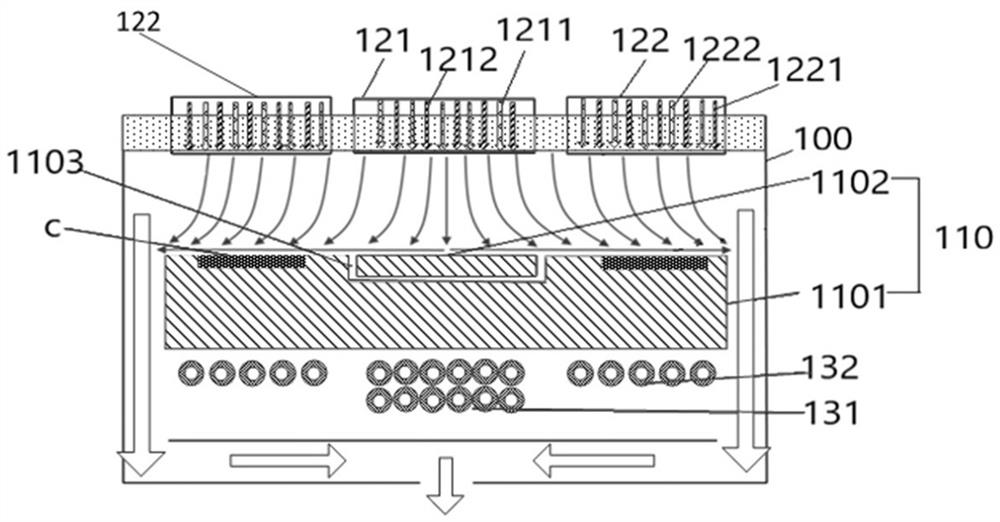

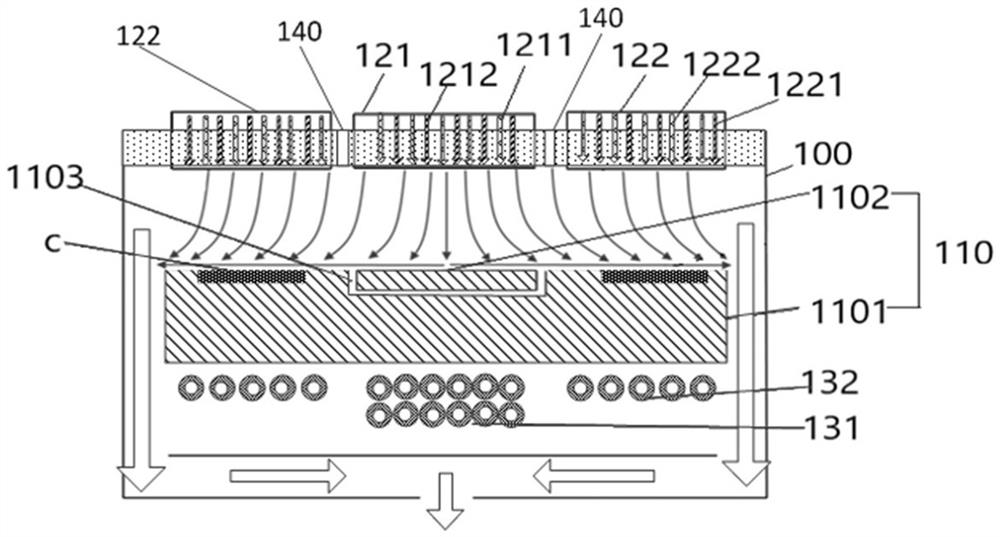

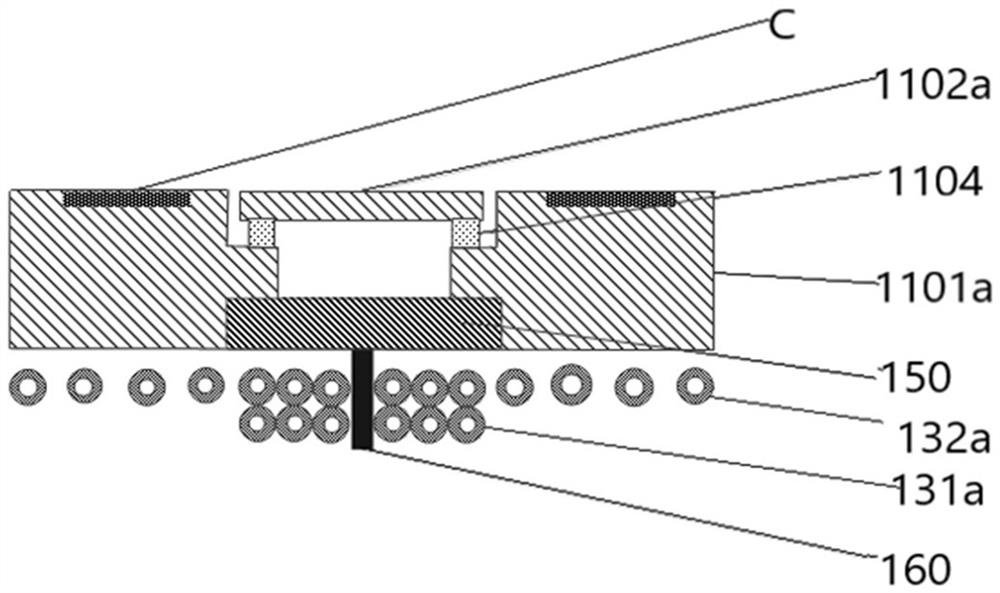

[0038] There are three main types of MOCVD reaction chambers, which are planetary air cushion rotating horizontal reaction chambers, high-speed rotating disk reaction chambers, and close-coupled spray reaction chambers.

[0039] In the planetary air cushion rotating horizontal reaction chamber, when the Group III reaction gas source and the Group V reaction gas source are used, the Group III reaction gas source and the Group V reaction gas source enter the reaction chamber from the three-laminar flow nozzle on the upper cover respectively, and pass through the grid The grid is forced to turn and flow radially to the outer edge horizontally along the 360-degree annular space between the base on which the substrate is placed and the ceiling, and flows out through the perforated quartz side ring. The base is a graphite base and the ceiling is a quartz ceiling. or graphite canopy. This flow pattern eliminates the sidewalls of the horizontal reaction chamber and therefore sidewall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com