Starch-fatty acid composite biofilm and preparation method thereof

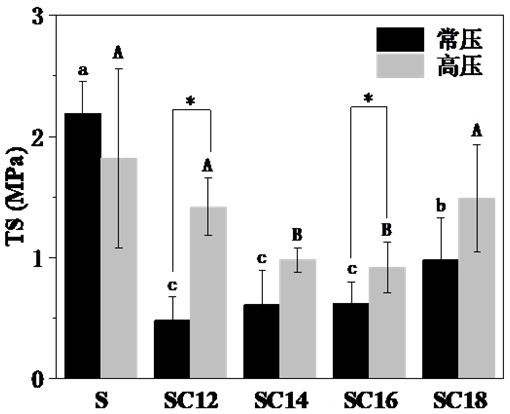

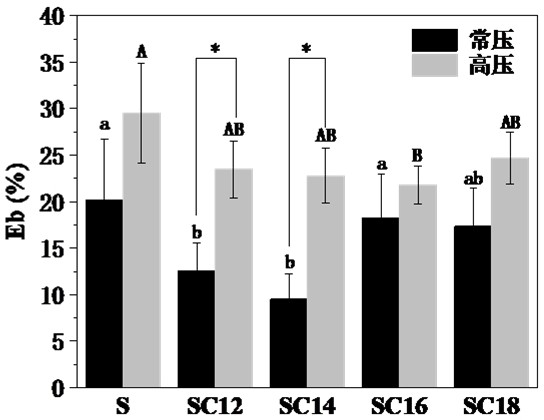

A fatty acid and biofilm technology, which is applied in the field of starch-fatty acid composite biofilm and its preparation, can solve the problems of reducing the tensile strength and elongation at break of starch film, poor film structure uniformity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

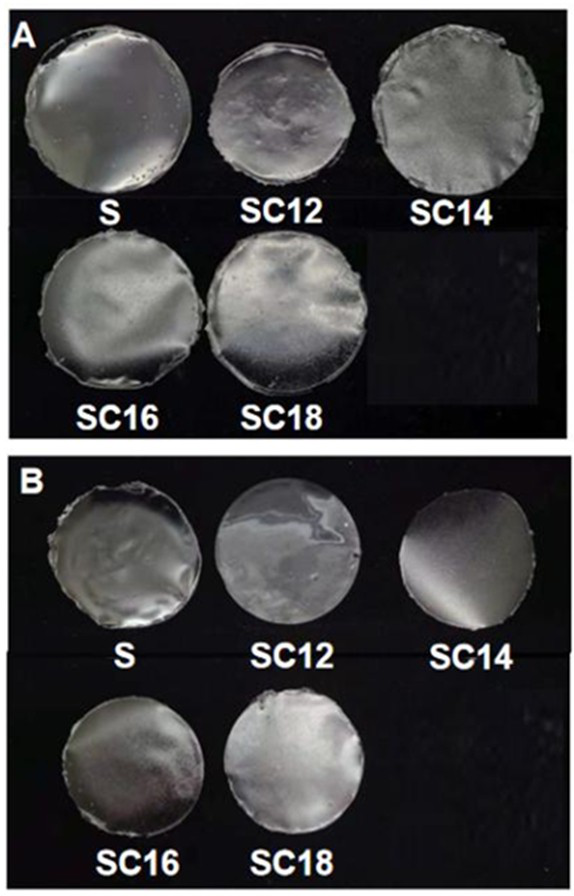

[0025] In this embodiment, prepare potato starch-myristic acid composite biofilm according to the following methods:

[0026] (1) Preparation of potato starch-myristic acid complex

[0027] Weigh potato starch and add it to distilled water at a ratio of 5% (w / v), heat and stir at 75°C for gelatinization for 20 minutes, add 2.5% (w / w) of potato starch dry weight myristic acid at 75°C Continue heating and stirring for 10 min to prepare potato starch-myristic acid complex. Put the compound into a high-pressure bag, the high-pressure parameters are pressure: 200 MPa, and the time is 30 min, and the normal pressure condition of 0.1 MPa is used as the control.

[0028] (2) Preparation of potato starch-myristic acid composite edible film

[0029] Weigh 50 g of the above potato starch-myristic acid complex, add 30% (w / w) glycerin to it, stir for 15 min to prepare a film-forming solution, and pour 30 g of the film-forming solution into a 90×90 mm petri dish, The composite film was o...

Embodiment 2

[0031] In this embodiment, prepare potato starch-lauric acid composite biofilm according to the following methods:

[0032] (1) Preparation of potato starch-lauric acid complex

[0033] Weigh potato starch and add it to distilled water at a ratio of 5% (w / v), heat and stir at 75°C for gelatinization for 20 minutes, add 2.5% (w / w) of potato starch dry weight lauric acid at 75°C Continue heating and stirring for 10 min to obtain the potato starch-lauric acid complex. Put the compound into a high-pressure bag, the high-pressure parameters are pressure: 300 MPa, and the time is 20 minutes, and the normal pressure condition of 0.1 MPa is used as a control.

[0034] (2) Preparation of potato starch-lauric acid composite edible film

[0035] Weigh 50 g of the above-mentioned potato starch-lauric acid complex, add 30% (w / w) glycerin to it, stir for 15 min to prepare a film-forming solution, and pour 30 g of the film-forming solution into a 90×90 mm Petri dish, The composite film wa...

Embodiment 3

[0037] In this embodiment, the potato starch-palmitic acid composite biofilm is prepared according to the following method:

[0038] (1) Preparation of potato starch-palmitic acid complex

[0039] Weigh potato starch and add it to distilled water at a ratio of 5% (w / v), heat and stir at 75°C for gelatinization for 20 minutes, add 2.5% (w / w) palmitic acid of the dry weight of potato starch to it at 75°C Continue heating and stirring for 10 min to obtain potato starch-palmitic acid complex. Put the compound into a high-pressure bag, the high-pressure parameters are pressure: 400 MPa, and the time is 30 minutes, and the normal pressure condition of 0.1 MPa is used as a control.

[0040] (2) Preparation of potato starch-palmitic acid composite edible film

[0041] Weigh 50 g of the above potato starch-palmitic acid complex, add 30% (w / w) sorbitol to it, stir for 15 min to prepare a film-forming solution, and pour 30 g of the film-forming solution into a 90×90 mm petri dish, The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com