Boron quantum dot as well as preparation method and application thereof

A technology of quantum dots and nanosheets, applied in the field of photothermal reagent preparation, can solve problems such as difficulty in large-scale quantitative production, harsh preparation process requirements, and limited clinical treatment applications, and achieve large-scale quantitative production, simple process, environmental protection, etc. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 A kind of preparation of boron quantum dot

[0031] The method for preparing boron quantum dots by liquid phase stripping comprises the following steps:

[0032] 1. Dissolve 100mg of amorphous boron powder in 100ml of deionized water to obtain a 1mg / ml boron nanosheet dispersion;

[0033] 2. Place the boron nanosheet dispersion obtained in step 1 in an ultrasonic machine with a frequency of 80KHz and a power of 400W, and after ultrasonication in an ice-salt bath at -10°C for 10 hours, a mixed solution is obtained;

[0034] 3. Centrifuge the mixed solution obtained in step 2 for 10 minutes in a centrifuge with a rotating speed of 10,000 rpm / s, take the supernatant and place it in a drying oven to remove water, and the obtained solid is boron quantum dots.

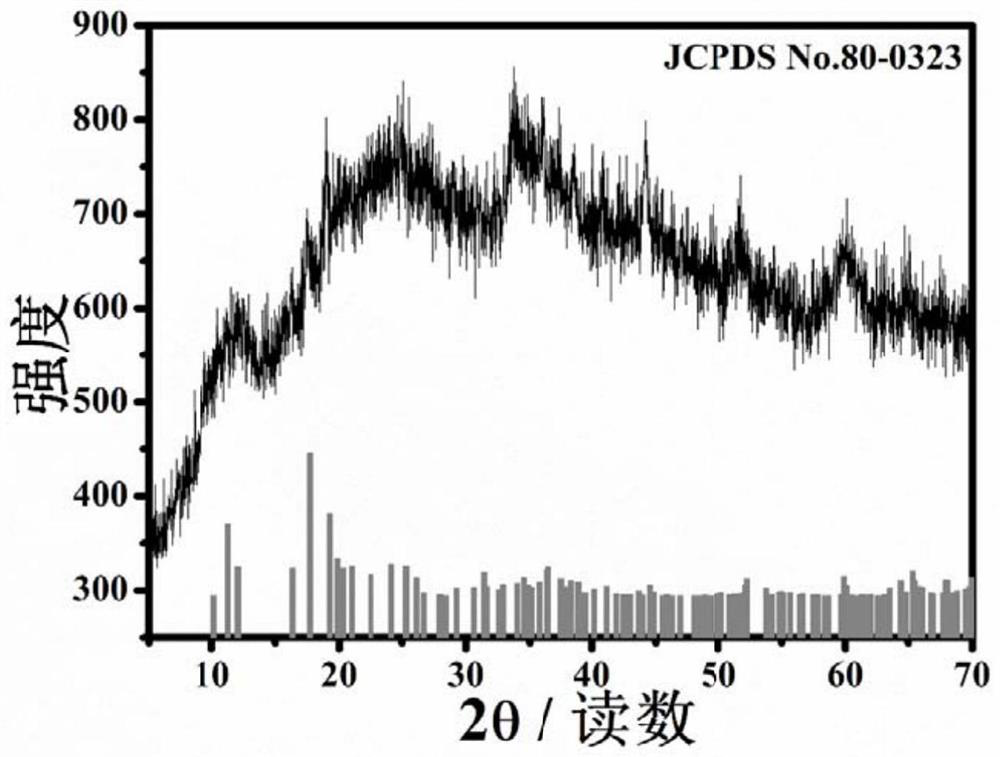

[0035] The boron quantum dots prepared in this embodiment are subjected to X-ray diffraction analysis, and the obtained X-ray diffraction spectrum is as follows figure 1 As shown, will figure 1 Compare...

Embodiment 2

[0039] Embodiment 2 A kind of preparation of boron quantum dot

[0040] The method for preparing boron quantum dots by liquid phase stripping comprises the following steps:

[0041] 1. Dissolve 200mg of amorphous boron powder in 100ml of deionized water to obtain a 2mg / ml boron nanosheet dispersion;

[0042] 2. Place the boron nanosheet dispersion obtained in step 1 in an ultrasonic machine with a frequency of 80KHz and a power of 400W, and after ultrasonication in an ice-salt bath at -10°C for 10 hours, a mixed solution is obtained;

[0043] 3. Centrifuge the mixed solution obtained in step 2 for 10 minutes in a centrifuge with a rotating speed of 10,000 rpm / s, take the supernatant and place it in a drying oven to remove water, and the obtained solid is boron quantum dots.

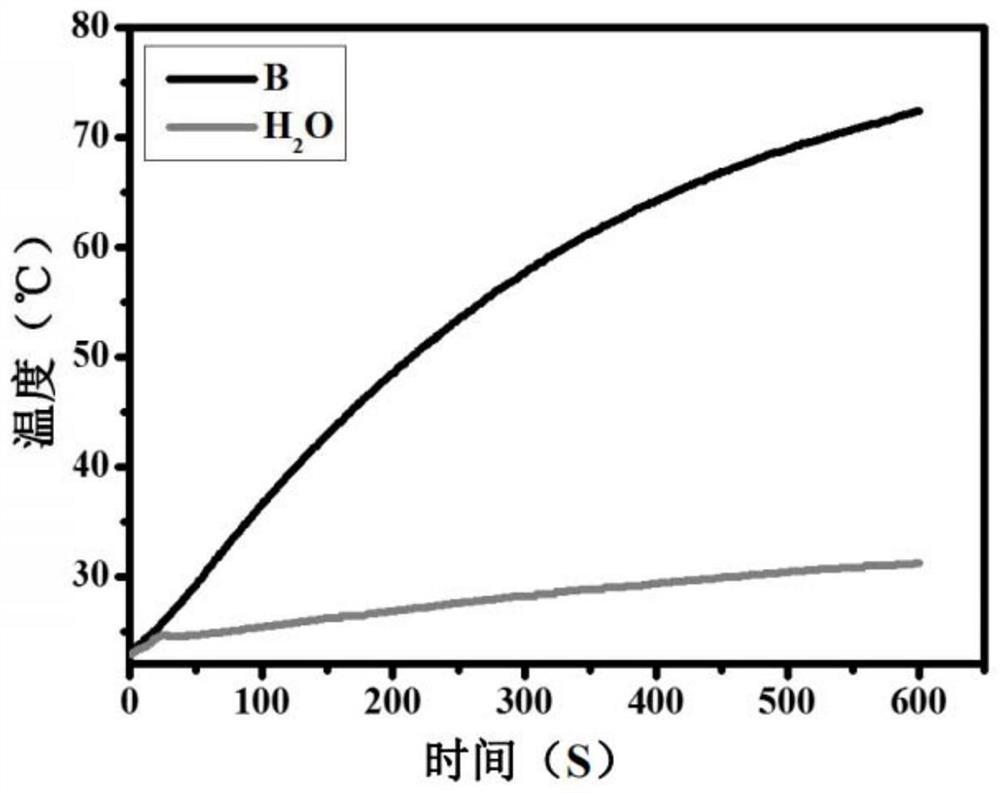

[0044] Using the method described in Example 1 to detect boron quantum dots, the results show that the boron quantum dots prepared in this example are uniform in size, with a particle size of 1 to 8 nm and...

Embodiment 3

[0045] Embodiment 3 A kind of preparation of boron quantum dot

[0046] The method for preparing boron quantum dots by liquid phase stripping comprises the following steps:

[0047] 1. Dissolve 500mg of amorphous boron powder in 100ml of deionized water to obtain a 5mg / ml boron nanosheet dispersion;

[0048] 2. Place the boron nanosheet dispersion obtained in step 1 in an ultrasonic machine with a frequency of 80KHz and a power of 400W, and after ultrasonication in an ice-salt bath at -10°C for 10 hours, a mixed solution is obtained;

[0049] 3. Centrifuge the mixed solution obtained in step 2 for 10 minutes in a centrifuge with a rotating speed of 10,000 rpm / s, take the supernatant and place it in a drying oven to remove water, and the obtained solid is boron quantum dots.

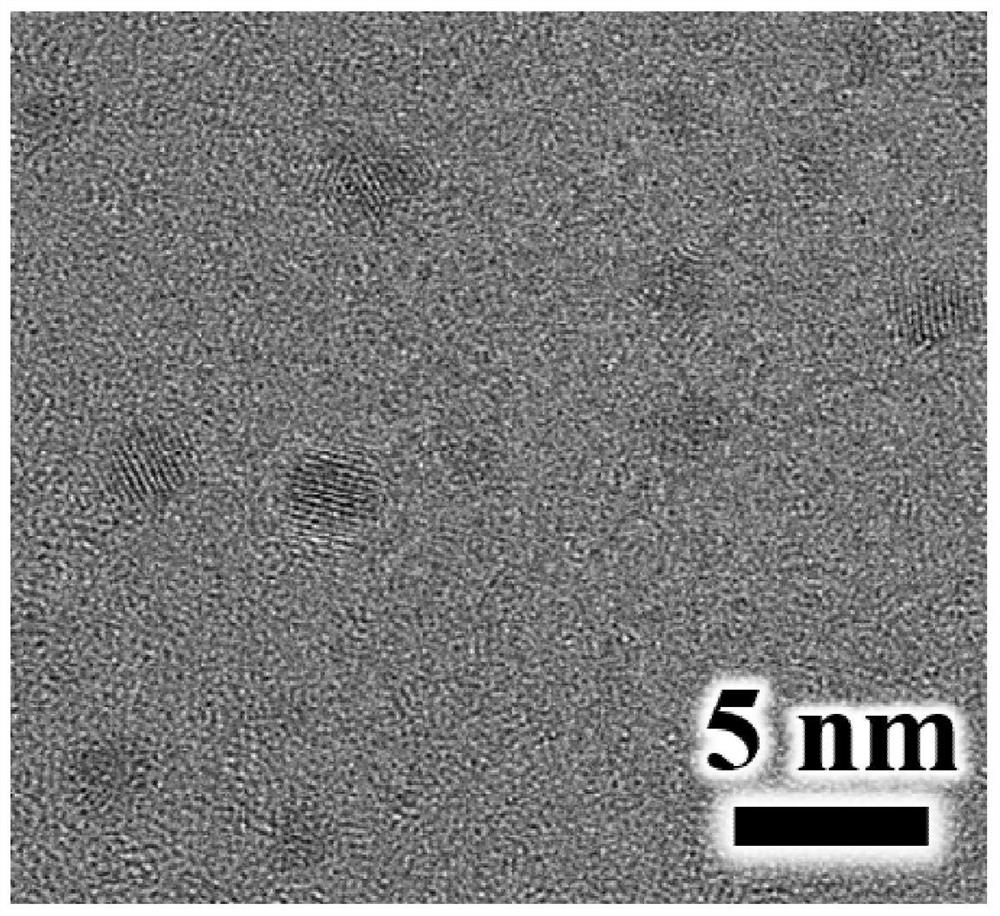

[0050] The method described in Example 1 is used to detect boron quantum dots, and the boron quantum dots prepared in this example are observed with a transmission electron microscope, and the transmissi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com