Rhombic phase CuCrSe2 nano material as well as preparation method and application thereof

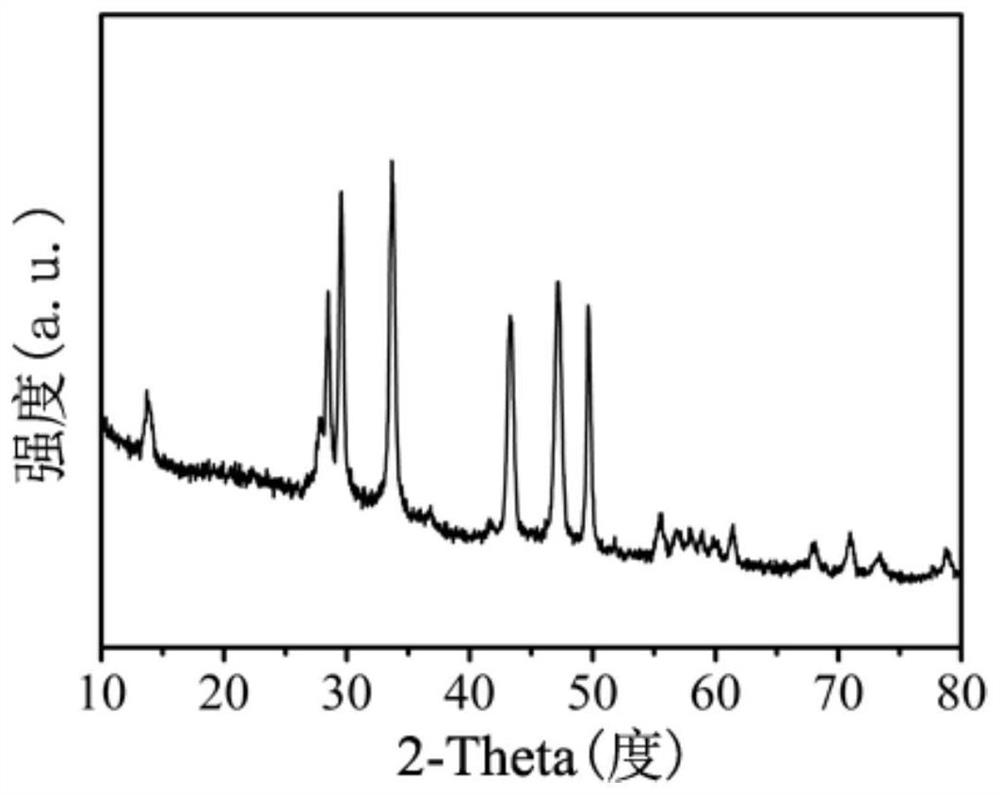

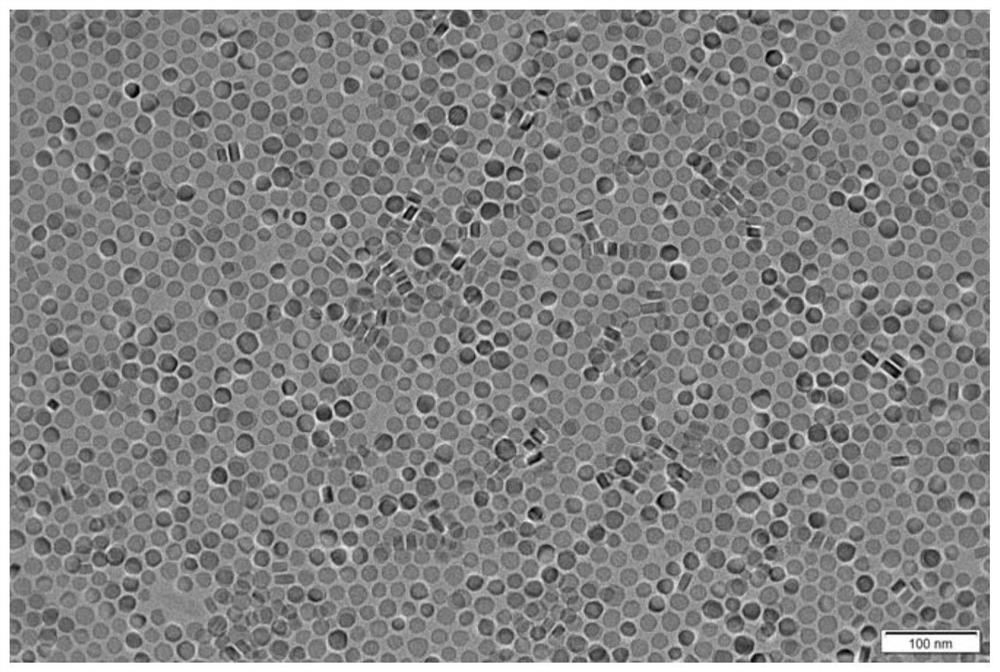

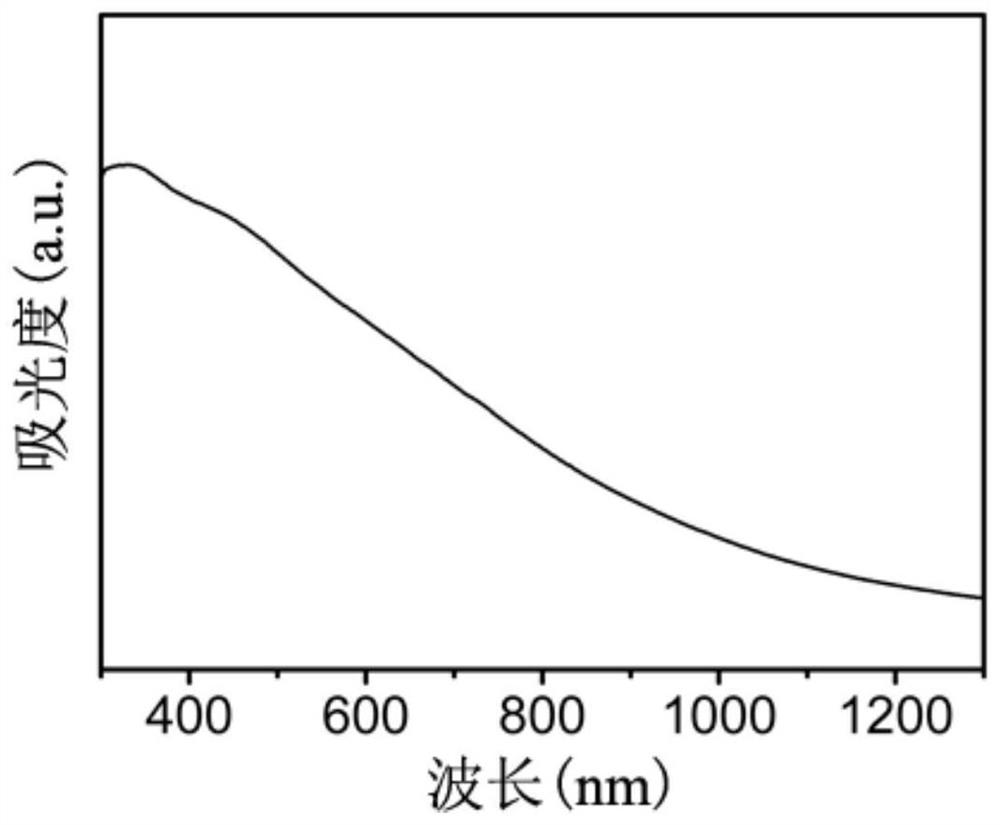

A nano-material, rhombohedral technology, applied in the field of CuCrSe2 preparation, can solve the problems of unfavorable CuCrSe2 industrialization development, limited CuCrSe2 performance, uncontrollable size, etc., to achieve excellent absorption capacity, high crystallinity, high monodispersity effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0038] A rhombohedral CuCrSe 2 The preparation of nanomaterials comprises the steps of:

[0039] (1) In a 100ml three-neck flask, add 0.1mmol copper acetylacetonate, 0.1mmol chromium acetylacetonate, 0.2mmol diphenyl diselenide and 6.0ml oleylamine respectively to obtain a mixed solution.

[0040] (2) Introduce nitrogen gas into the three-neck flask in step (1), and heat the mixture to 130°C for 30 minutes under magnetic stirring to remove moisture and low-boiling impurities in the reaction system.

[0041] (3) Continue to heat the mixture to 280°C and keep it warm for 30 minutes, cool to room temperature after the reaction, and centrifuge to separate the solid product in the reaction solution, then wash the solid product centrifugally with cyclohexane and absolute ethanol for 3 Second, the obtained solid product is the target product.

no. 2 example

[0043] A rhombohedral CuCrSe 2 The preparation of nanomaterials comprises the steps of:

[0044] (1) In a 100ml three-neck flask, add 0.1mmol cuprous chloride, 0.1mmol chromium acetylacetonate, 0.2mmol diphenyl diselenide and 6.0ml organic solvent (oleic acid and oleylamine are formed at a volume ratio of 1:5) mixed solvent) to obtain a mixed solution.

[0045] (2) Introduce nitrogen gas into the three-neck flask in step (1), and heat the mixture to 130°C for 30 minutes under magnetic stirring to remove moisture and low-boiling impurities in the reaction system.

[0046] (3) Continue to heat the mixture to 280°C and keep it warm for 30 minutes, cool to room temperature after the reaction, and centrifuge to separate the solid product in the reaction solution, then wash the solid product centrifugally with cyclohexane and absolute ethanol for 3 Second, the obtained solid product is the target product.

no. 3 example

[0048] A rhombohedral CuCrSe 2 The preparation of nanomaterials comprises the steps of:

[0049] (1) In a 100ml three-necked flask, add 0.1mmol copper acetylacetonate, 0.1mmol chromium acetylacetonate, 0.1mmol dibenzyl diselenide and 6.0ml organic solvent (formed by octadecene and oleylamine at a volume ratio of 1:5) mixed solvents) to obtain a mixed solution.

[0050] (2) Introduce nitrogen gas into the three-neck flask in step (1), and heat the mixture to 130°C for 30 minutes under magnetic stirring to remove moisture and low-boiling impurities in the reaction system.

[0051] (3) Continue to heat the mixture to 280°C and keep it warm for 30 minutes, cool to room temperature after the reaction, and centrifuge to separate the solid product in the reaction solution, then wash the solid product centrifugally with cyclohexane and absolute ethanol for 3 Second, the obtained solid product is the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com