Synchronous alkali-resistant hollow pipe production device for non-ferrous metal smelting waste gas treatment

A non-ferrous metal and waste gas treatment technology, applied in the field of non-ferrous metal smelting, can solve the problems of reduced stability, less glue content and more glue in rectangular plates, and achieve the effect of reducing glue overflow and preventing glue faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

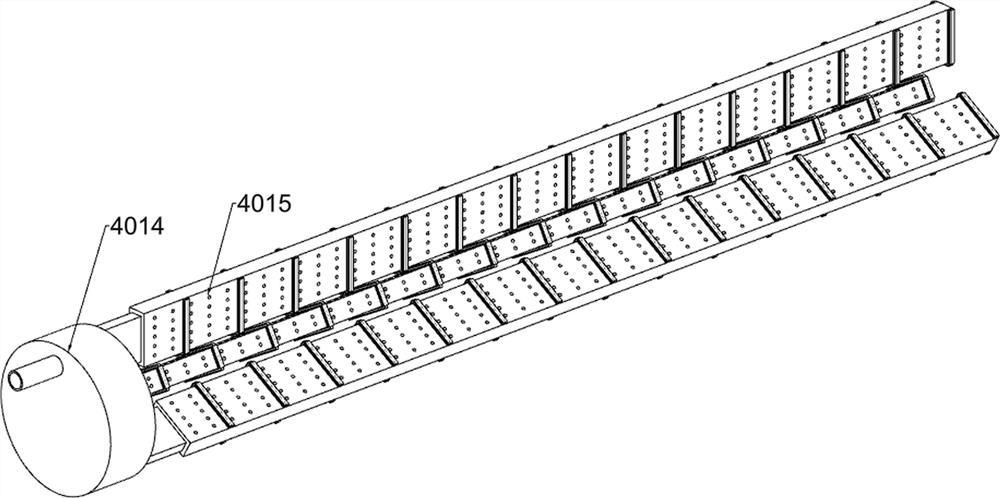

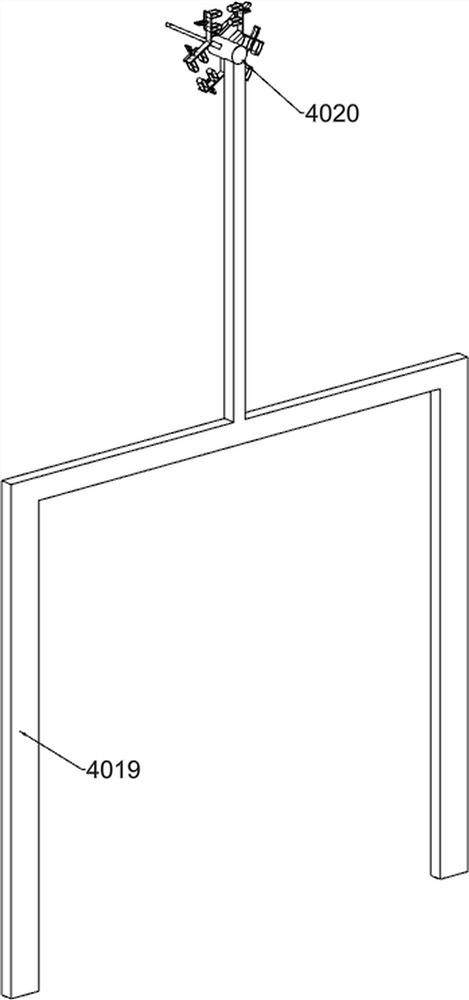

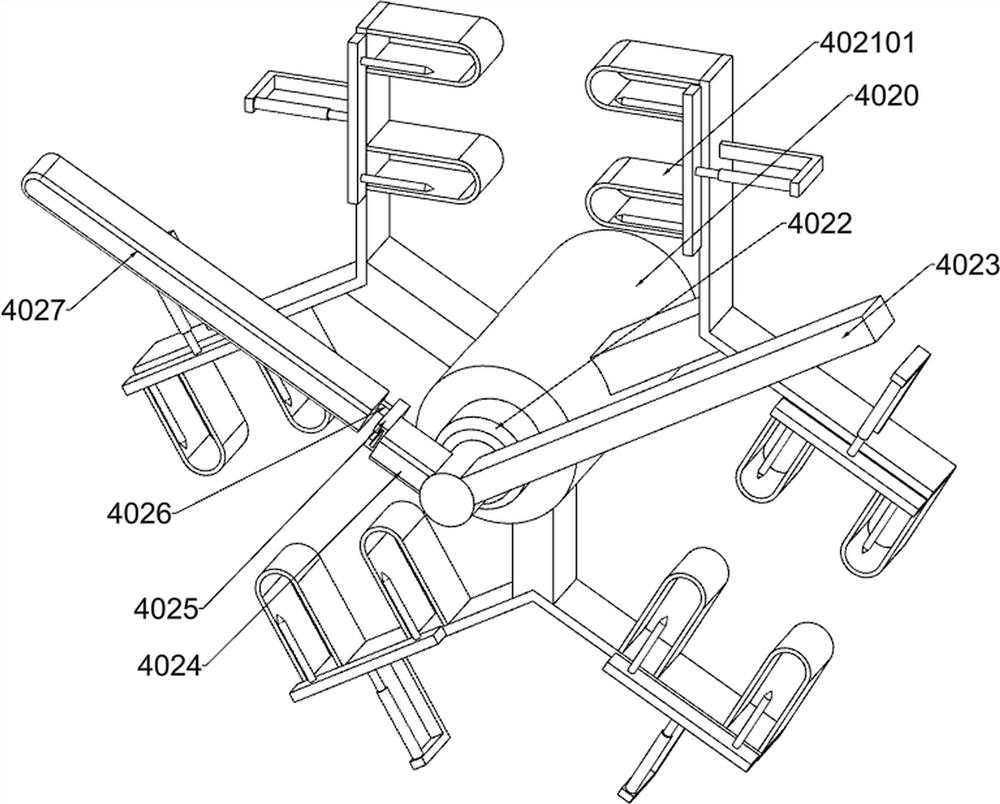

[0033] A synchronous alkali-resistant hollow tube production device for non-ferrous metal smelting waste gas treatment, such as Figure 1-3 As shown, it includes a bottom plate 1, a base 2, an anti-skid pad 3, a first support frame 4, a second support frame 5, a third support frame 6, a fourth support frame 7, a fifth support frame 8, a blanking assembly, a transportation Components and bonding components; Bottom plate 1 is fixed to four sets of bases 2; Bottom plate 1 is fixed to the first support frame 4; Bottom plate 1 is fixed to the second support frame 5; Bottom plate 1 is connected to the third support frame 6 affixed connection; base plate 1 is affixed with the fourth support frame 7; base plate 1 is affixed with the fifth support frame 8; four groups of bases 2 are respectively affixed with four groups of anti-skid pads 3; the first support frame 4 and The large plastic plate is cut into three equal parts and fixed in a circular array of blanking components; the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com