Full-automatic blanking device for quantitative cutting of alloy bars

A fully automatic alloy and bar material technology, which is applied to shearing devices, accessories of shearing machines, transportation and packaging, etc., can solve the problems of low automation, low production efficiency, and danger-prone, so as to improve product quality and The effect of production efficiency and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, a method for improving the machining accuracy of alloy circumferential test rods proposed according to the present invention will be described in detail. , structure, feature and effect thereof, detailed description is as follows.

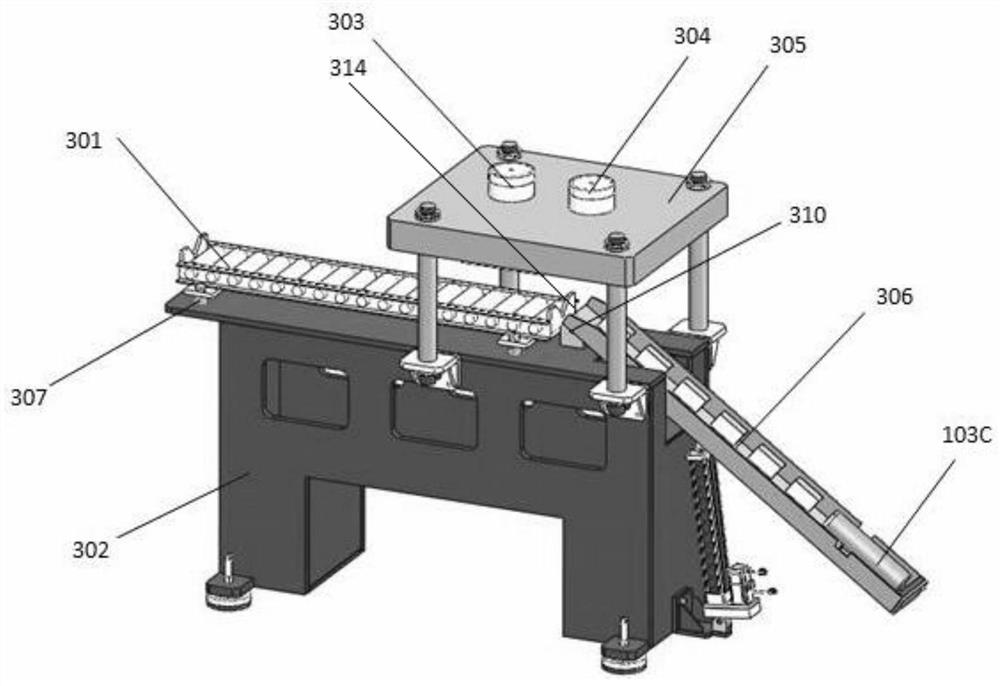

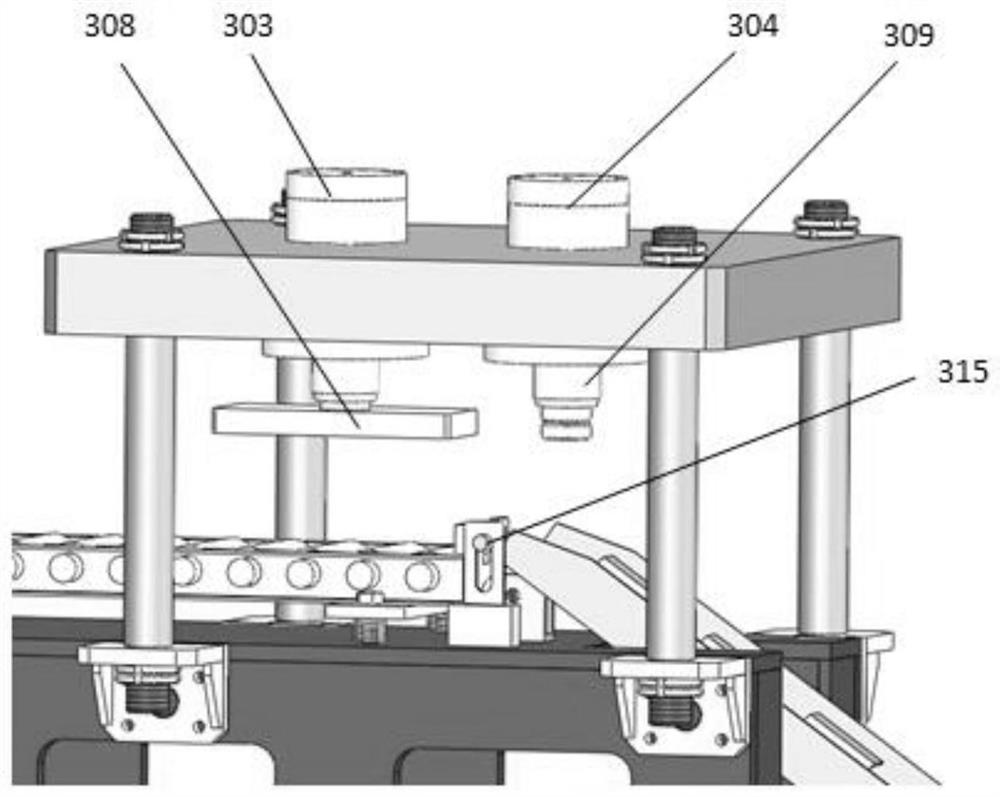

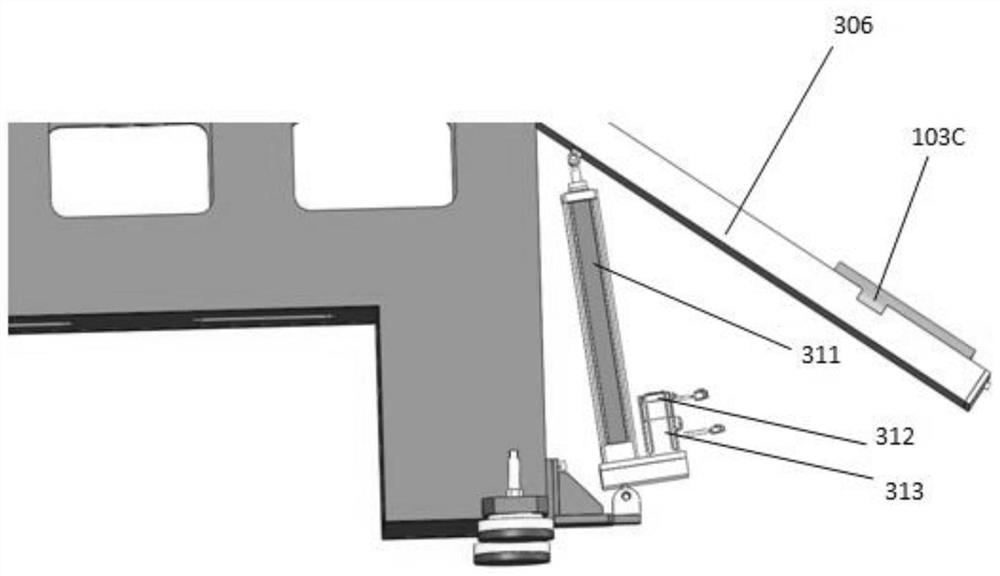

[0024] Such as Figure 1-Figure 6 As shown, the automatic blanking device for quantitative cutting of alloy bars of the present invention includes a crushing device and a truss manipulator. The truss manipulator is located on the side of the crushing device where the material receiving tank 306 is located, and the truss manipulator passes through the pneumatic gripper on it. 501 corresponds to the bar stock in the material receiving groove 306, wherein:

[0025] Such as Figure 1-Figure 2 As shown, the crushing device includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com