Automatic iron sheet stamping equipment

A kind of stamping equipment and automatic technology, applied in the direction of pushing out equipment, metal processing equipment, feeding devices, etc., can solve the problem of inconvenient collection of stamped and formed iron sheets, and achieve the effect of convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

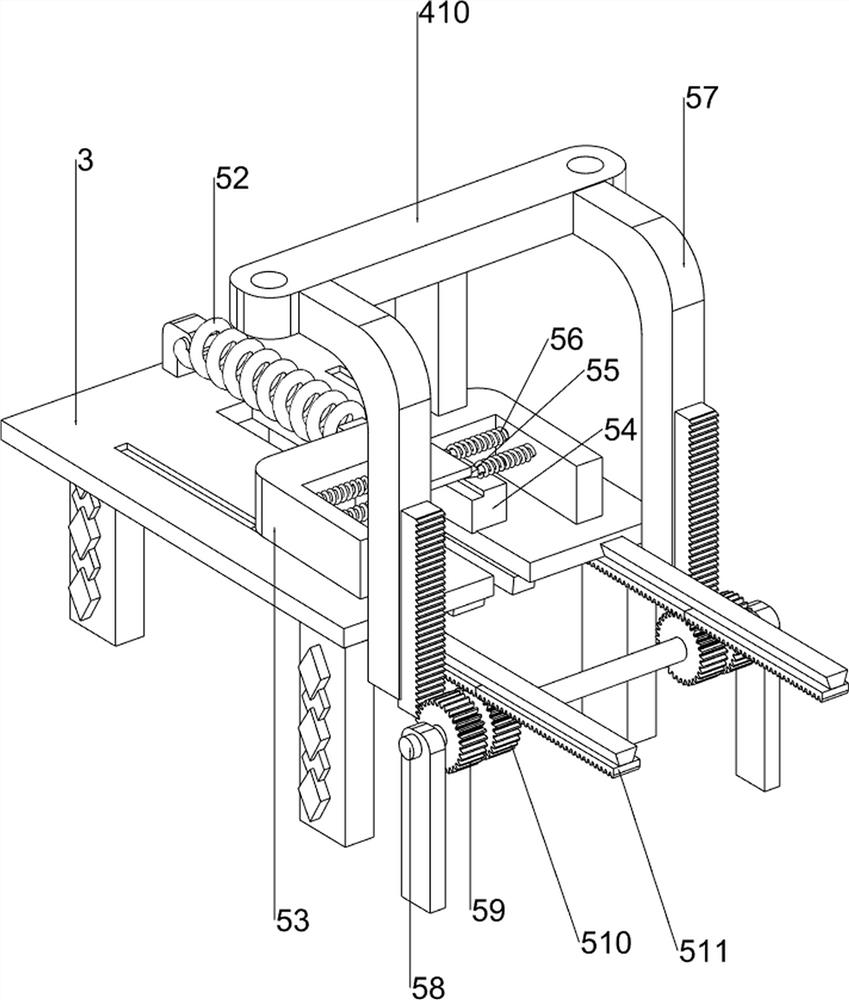

[0026] A kind of iron sheet automatic stamping equipment, such as figure 1 and figure 2 As shown, it includes a bottom plate 1, a biaxial motor 2, a table 3, a pressing mechanism 4 and a pushing mechanism 5. A pressing mechanism 4 is provided on the middle side of the top, and the parts of the pressing mechanism 4 are connected with the output shaft of the biaxial motor 2. A pushing mechanism 5 is installed on the table 3, and the parts of the pushing mechanism 5 are connected with the parts of the pressing mechanism 4 .

[0027] When people need to automatically stamp the iron sheet, people first place the iron sheet on the parts of the pushing mechanism 5, and then people start the biaxial motor 2, and the rotation of the parts of the biaxial motor 2 drives the rotation of the parts of the pressing mechanism 4, The rotation of the parts of the pressing mechanism 4 drives the parts of the pressing mechanism 4 to move up and down, and the parts of the pressing mechanism 4 m...

Embodiment 2

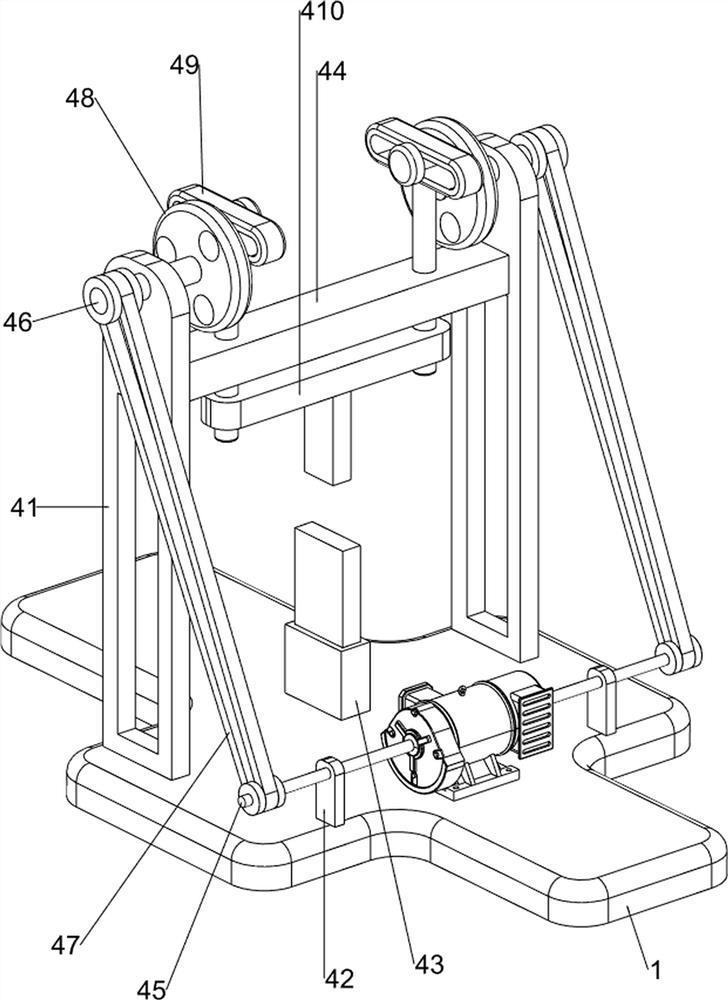

[0029] On the basis of Example 1, such as image 3 , Figure 4 and Figure 5 As shown, the pressing mechanism 4 includes a first support frame 41, a second support frame 42, a shrink frame 43, a first fixed rod 44, a first rotating shaft 45, a second rotating shaft 46, a belt assembly 47, and a disc 48 , the pressing push rod 49 and the stamping sheet 410, the first support frame 41 is provided on the left and right sides of the top of the bottom plate 1, the second support frame 42 is provided on the left and right sides of the top of the front side of the bottom plate 1, and the middle of the top of the bottom plate 1 is provided with a shrink Frame 43, the first support frame 41 is slidingly connected with the first fixed rod 44, the output shaft of the biaxial motor 2 is provided with the first rotating shaft 45, and the first rotating shaft 45 passes through the second supporting frame 42 , the upper part of the first support frame 41 is rotatably connected with a secon...

Embodiment 3

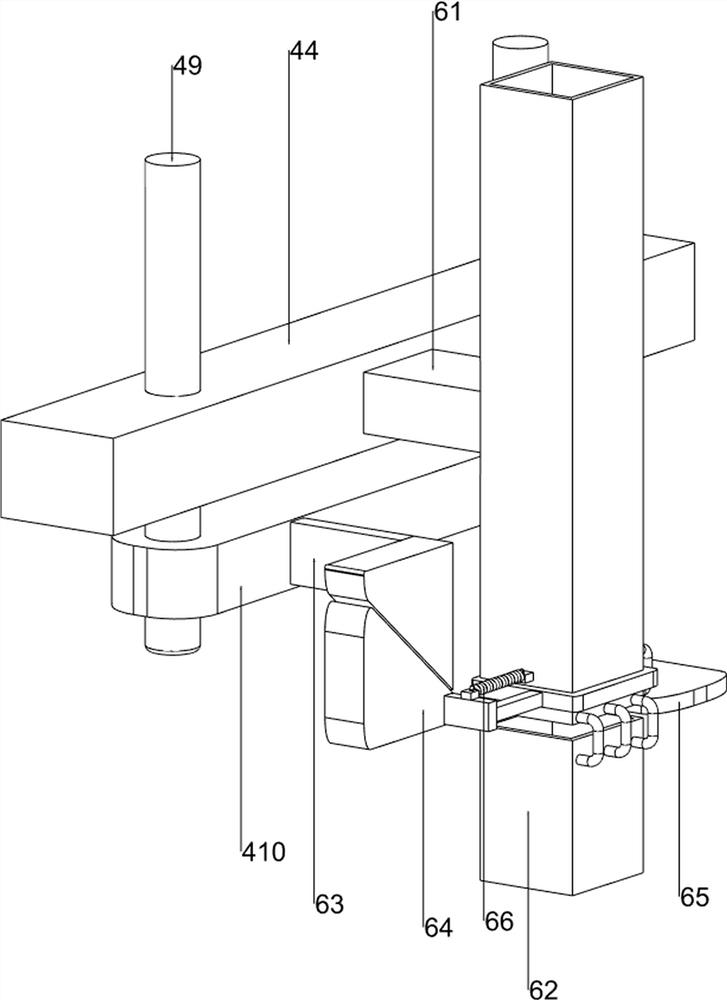

[0034] On the basis of Example 2, such as Figure 6 , Figure 7 and Figure 8 As shown, a blanking mechanism 6 is also included, and the blanking mechanism 6 includes a second fixed rod 61, a blanking plate 62, a first wedge block 63, a second wedge block 64, a material blocking plate 65 and a second tension spring 66 , the middle part of the rear side of the first fixed rod 44 is provided with a second fixed rod 61, the rear part of the second fixed rod 61 is connected with a blanking plate 62, and the right side of the stamping sheet 410 rear portion is provided with a first wedge-shaped block 63, and the blanking plate 62 The lower side is slidingly connected with a material stopper 65, and the right part of the material stopper 65 is connected with a second wedge-shaped block 64, and the second wedge-shaped block 64 is squeeze-fitted with the first wedge-shaped block 63, and the second wedge-shaped block 64 is connected with the blanking plate 62. A second tension spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com