Preparation method of metal belt for manufacturing backlight plate of folding screen mobile phone

A technology of backlight panels and metal strips, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of immature folding screen mobile phone technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

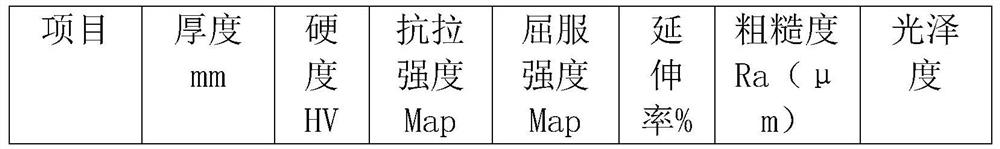

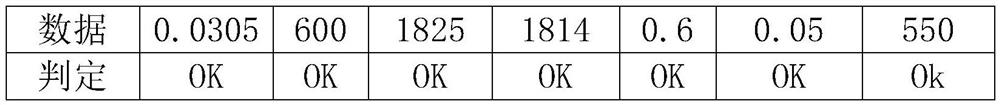

Examples

Embodiment 1

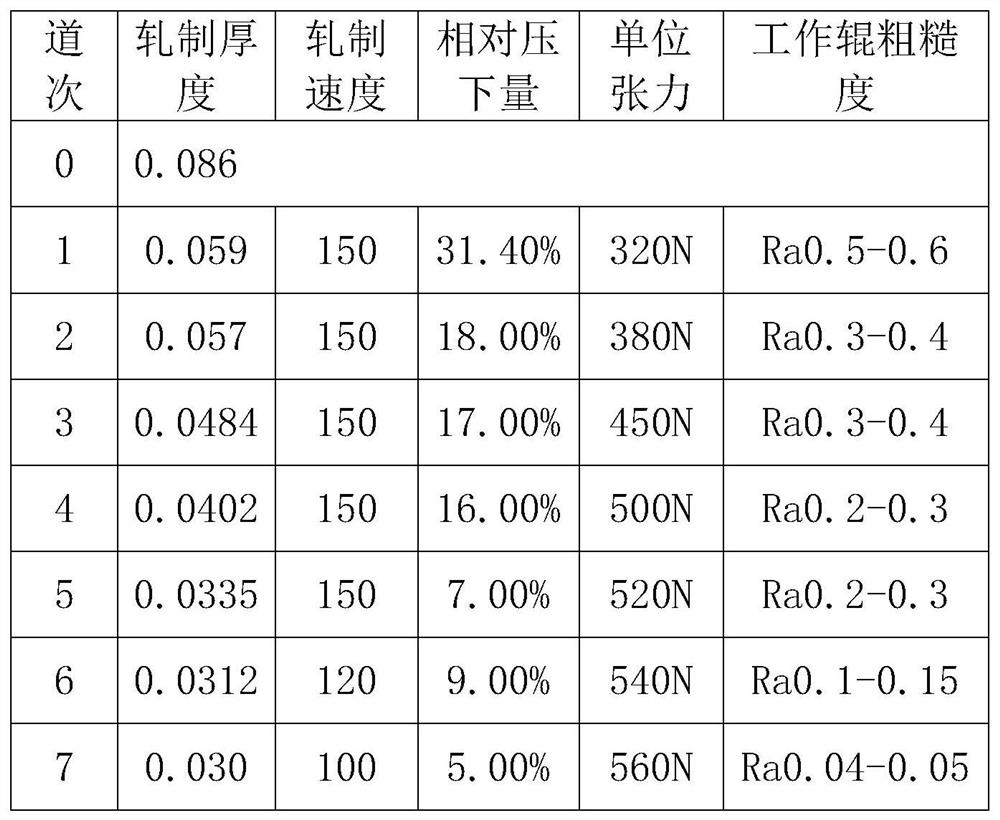

[0028] In order to achieve the purpose of the present invention, in one of the embodiments of the present invention, a method for preparing a metal strip for making a backlight panel of a folding screen mobile phone is provided, comprising the following steps:

[0029] S1, one rolling;

[0030] Using a 20-roll rolling mill, after 6-7 passes of rolling, the 0.225mm semi-finished steel strip is rolled into a semi-finished steel strip with a thickness of 0.17mm, and the rough grinding roll of Ra0.5-0.7um is selected as the working roll for rolling;

[0031] S2, a solid solution annealing;

[0032] The 0.17mm semi-finished steel strip after one rolling passes through the degreasing and cleaning section of the continuous annealing line, after removing the grease remaining on the surface of the semi-finished steel strip during rolling, it is dried and enters a bright annealing furnace protected by full hydrogen, with a dew point of -45~ -55°C, the annealing speed is 22m / min, the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com