Diamond gel highlight and preparation method thereof

A technology of jelly and diamond, which is applied in the field of diamond jelly highlights and its preparation. It can solve the problems of low smoothness, stickiness, and poor use feeling, and achieve the effect of enhancing smoothness, reducing stickiness, and improving use feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

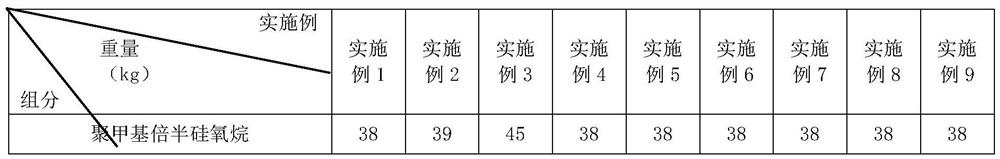

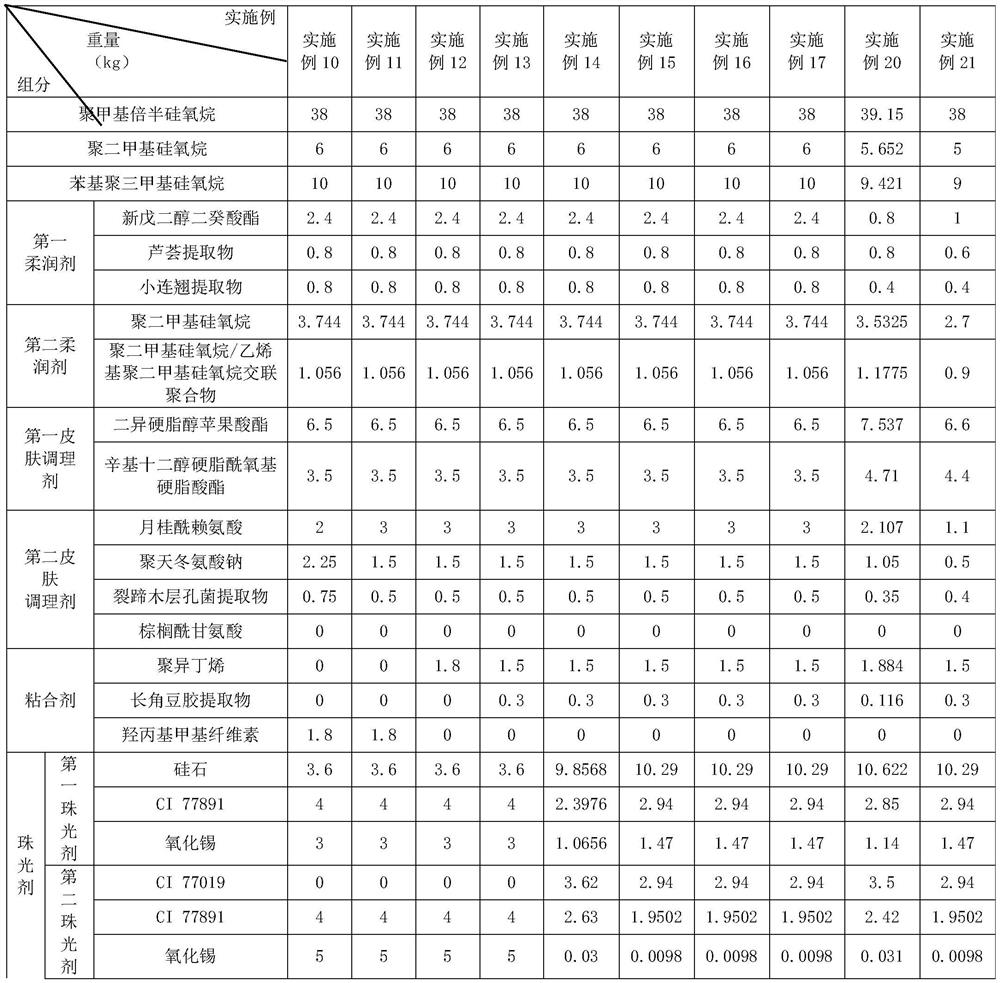

Embodiment 1

[0059] Embodiment 1: a kind of diamond jelly high light, the specific components and weight included are as shown in table 1, made by the following steps: S1: polymethylsilsesquioxane, polydimethylsiloxane, Phenyl polytrimethicone and the second emollient are mixed, the temperature is controlled at 80°C during the mixing process, and the stirring speed is 500r / min during the mixing process, and the first mixture is obtained after stirring evenly;

[0060] S2: Mix and stir the first emollient, the first skin conditioning agent and the second skin conditioning agent at a stirring speed of 800 r / min, and obtain the second mixture after stirring evenly;

[0061] S3: first cool down the first mixture to 50°C, and the cooling rate is 4°C / min; then add the second mixture to the first mixture, stir during the mixing process, and add pearlescent agent, adhesive, and preservative after stirring evenly , continue to stir, and homogenize for 30 minutes after stirring evenly to obtain a di...

Embodiment 2-3

[0062] Embodiment 2-3: A diamond jelly highlight, the difference from Example 1 is that the control temperature in step S1 is 60°C, the homogenization time in step S3 is 10min, and the specific components and weights are different at the same time, the specific components included Components and weight are shown in Table 1.

Embodiment 4-5

[0063] Embodiment 4-5: a kind of diamond jelly highlight, the difference with embodiment 1 is that the second emollient has different components and weight, and the specific components and weight included are as shown in table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com