Millimeter wave antenna

A millimeter wave antenna and horn antenna technology, applied in the field of antenna equipment, can solve problems such as adverse effects of antenna radiation performance, unfavorable antenna expansion, unfavorable expansion, etc., and achieve the effects of high engineering application value, expanding antenna bandwidth, and reducing processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

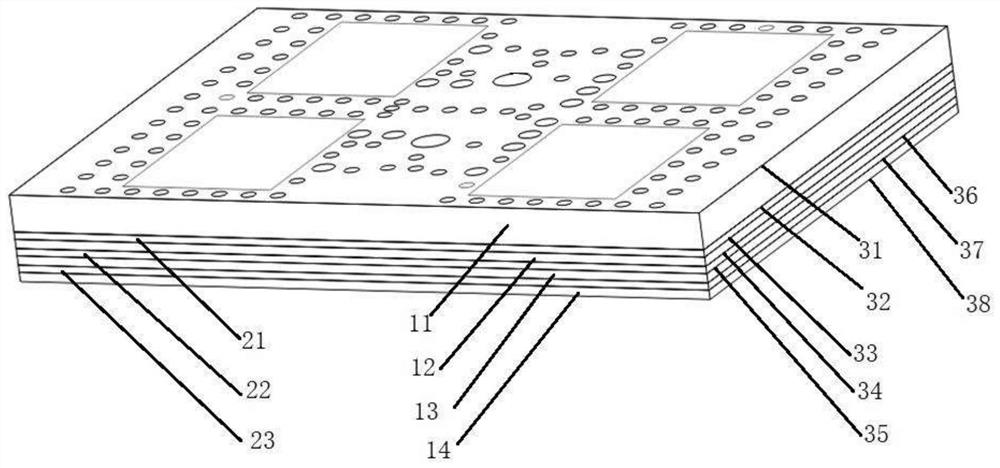

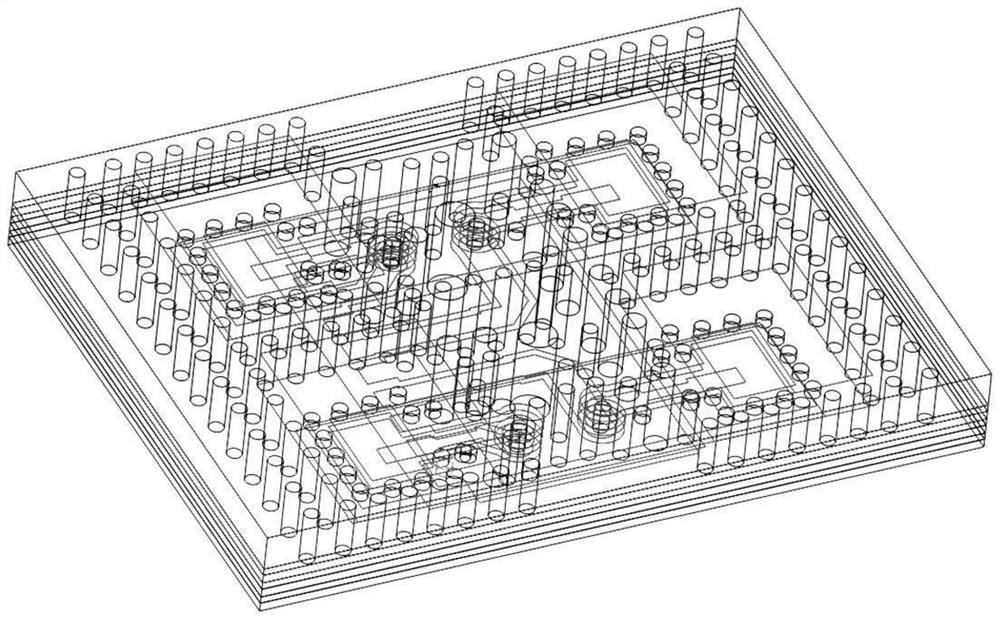

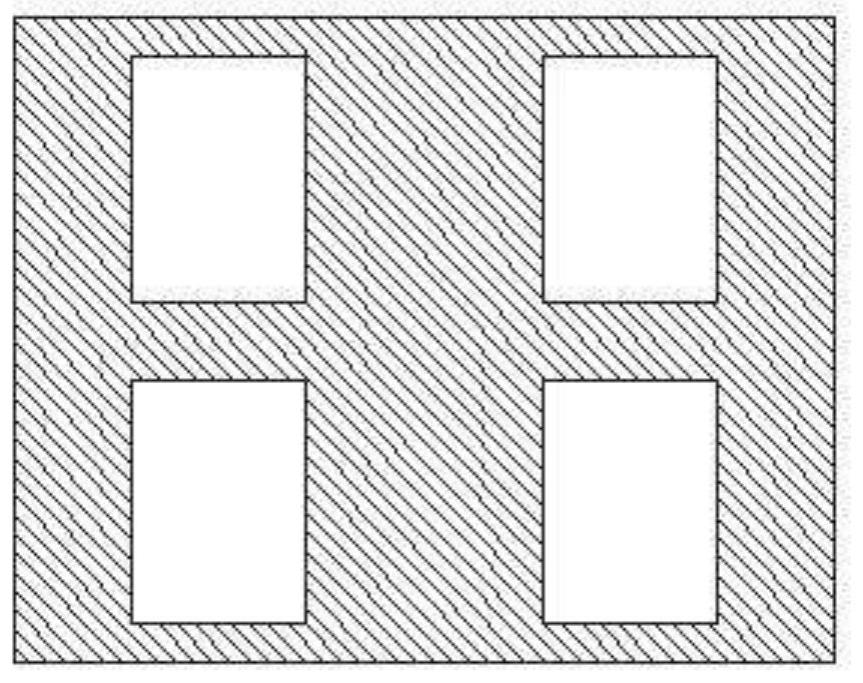

[0062] A millimeter-wave antenna working at 77-81GHz is provided here. It includes 4 layers of Rogers3003 microstrip boards with a thickness of 0.127mm. 0.1mm prepreg is used for bonding. The antenna includes 4 antenna units, the size of the antenna is 10mm in length and 7.6mm in width, and the distance between the centers of the horn cavity of the antenna unit is 5mm on the long side and 3.8mm on the wide side. The 4-layer microstrip board corresponds to 8 copper clad layers. Looking from top to bottom, the pattern of each copper clad layer is as follows: Figure 3 to Figure 9 shown. Correspondingly, in order to shield and isolate the antenna unit and provide continuous grounding between the upper and lower layers, 6 different types of metallized holes are set up. The minimum diameter of the metallized holes is 0.2mm, and the positions of the metallized holes are as follows: Figure 10 ~ Figure 15 shown.

[0063] The first metallized via hole, the second metallized via hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com