In-groove roller bed full-immersion type salt bath heat treatment device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

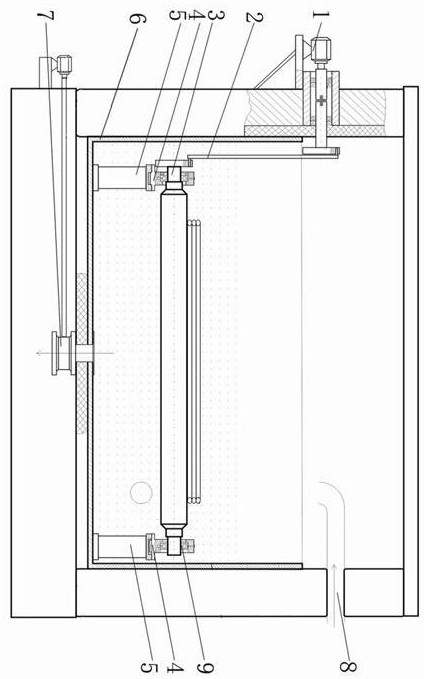

[0044] see Figure 1 to Figure 4 , a fully submerged salt bath heat treatment device with a roller table in a tank, comprising a salt bath tank 6, a motor 1 and a support 5.

[0045] Wherein, the bottom of the salt bath tank 6 is provided with a base, the two sides of the salt bath tank 6 are provided with insulation walls, and the top of the insulation wall is provided with an insulation cover.

[0046] A plurality of conveying rollers 3 are arranged in the salt bath tank 6 , and a continuous conveying roller table is formed by the plurality of conveying rollers 3 .

[0047] Both ends of each conveying roller 3 are installed in the salt bath tank 6 through the support 5 and below the molten salt liquid level. The top of the support 5 is detachably connected to the bearing seat 4, and the bearing seat 4 is equipped with a bearing 9. The bearing 9 The inner ring 14 is connected to the end of the conveying roller 3 .

[0048] The motor 1 is installed outside the salt bath tank...

Embodiment 2

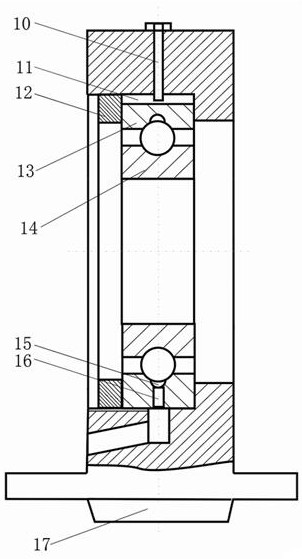

[0054] The main reasons for bearing damage caused by molten salt are: first, the sediment or scale in the molten salt accumulates in the raceway of the outer ring of the bearing, causing wear to the bearing 9; second, when the salt bath stops working, it is necessary to put the salt bath 6 The molten salt in the inner ring is emptied, and the molten salt accumulated in the raceway of the outer ring cannot be discharged. Crystallized salt is produced after the temperature drops, and the bearing 9 is damaged due to ball rolling.

[0055] In order to solve the above problems, this embodiment is further optimized on the basis of embodiment 1, specifically:

[0056] An annular sewage discharge groove 15 is processed on the raceway of the outer ring 13 of the bearing 9, and the bearing housing 4 is correspondingly provided with an interconnected sewage discharge channel 16, and one end of the sewage discharge flow channel 16 communicates with the sewage discharge groove 15 of the bea...

Embodiment 3

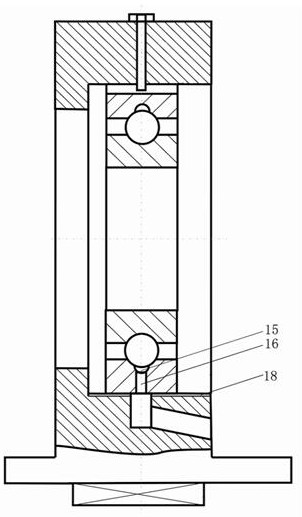

[0063] This embodiment is further optimized on the basis of the foregoing embodiments, specifically:

[0064] A bearing cap 12 for fixing the bearing 9 is installed on the bearing block 4 at the power end of the conveying roller 3 .

[0065] The bearing 9 at the other end is axially slidably installed in the bearing seat 4, and the bearing seat 4 is provided with a groove 18 vertically intersecting and communicating with the sewage flow channel 16. The function of the groove 18 is to prevent the axial displacement of the bearing 9. , keep the sewage flow channel 16 unimpeded.

[0066] Through the design that the bearing 9 on one side of the conveying roller 3 is fixedly installed, and the bearing 9 on the other side is axially slidably installed, there is room for the elongation of the conveying roller 3 due to thermal deformation, and the performance of the conveying roller 3 in high-temperature molten salt is improved. stability.

[0067] In addition, a positioning groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com