Vacuum vulcanizing setting machine capable of achieving uniform heating of shoes

A technology of uniform heating and setting machine, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of inability to achieve uniform heating, poor sealing performance, and external air entry, so as to reduce adverse interference, improve utilization rate, The effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

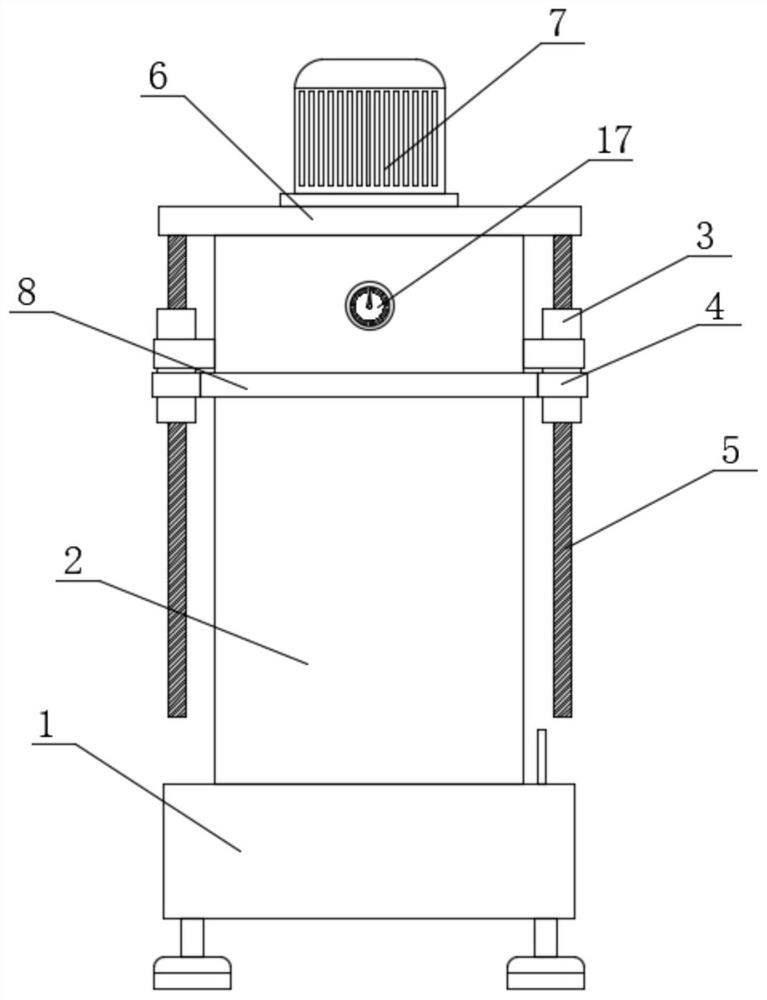

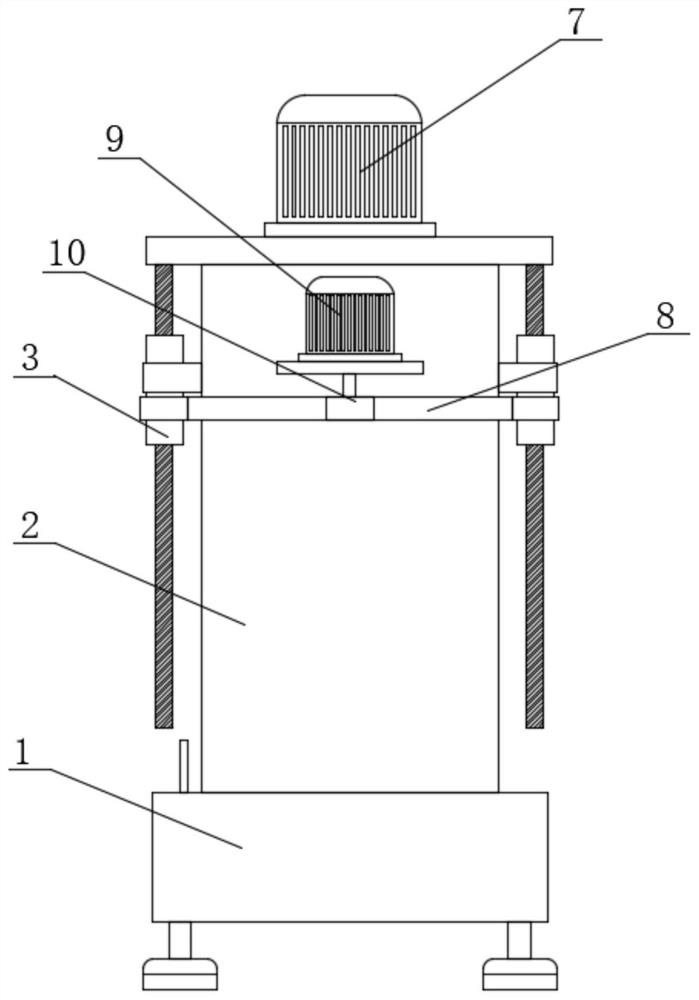

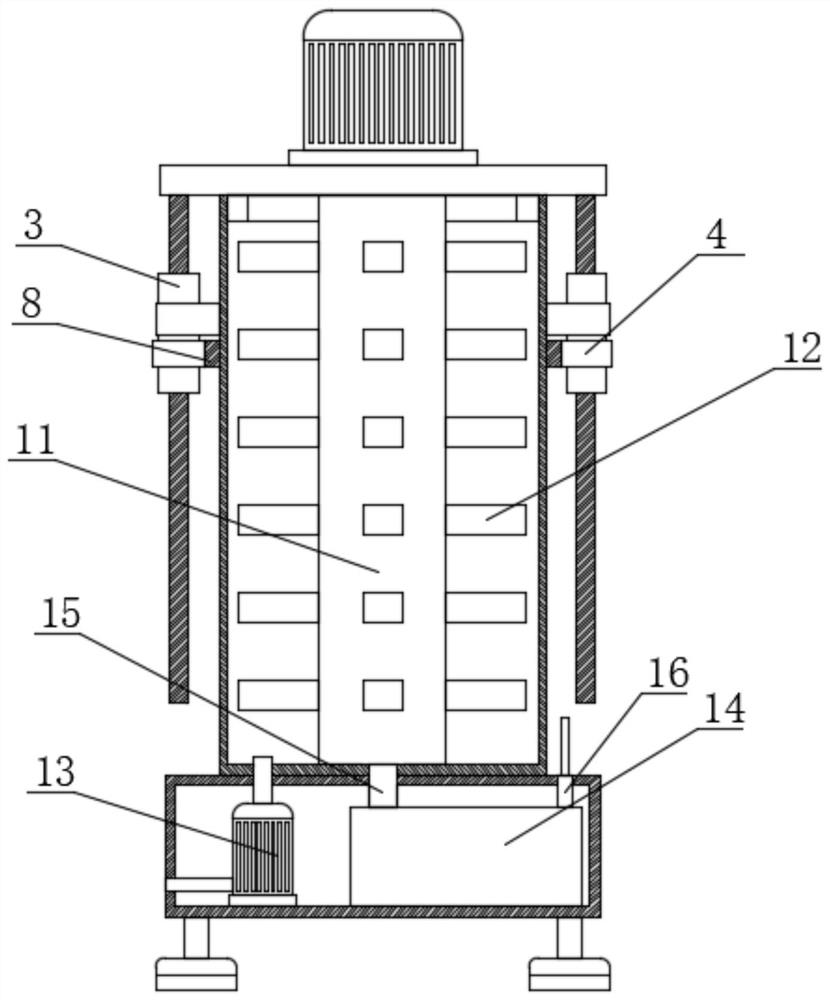

[0034] refer to Figure 1-9, in this embodiment, a vacuum vulcanization and setting machine that can realize uniform heating of shoes is proposed, including an installation box 1, a drying box 2 is fixedly installed on the top of the installation box 1, and the top of the drying box 2 is sealed and clamped There is a cover plate 6, the bottom of the cover plate 6 is equipped with a rubber ring that can be adapted to the inner wall of the drying box 2, so as to avoid the problem of leakage, a transmission assembly is installed on the drying box 2, and the transmission assembly and the cover plate are installed. 6 is connected, the bottom of the cover 6 is fixedly installed with a dispersion box 11, the dispersion box 11 is provided, which can realize the synchronous movement of the shoes, and can facilitate the dispersion and transportation of gas. The bottom of the dispersion box 11 extends into the drying box 2, and the dispersion box 11 A plurality of placement boxes 12 are ...

Embodiment 2

[0039] On the basis of the first implementation, the difference of this embodiment is that the air jet assembly includes a connection box 25, a plurality of shunt pipes 26 and two drying hoods 27, and the connection box 25 is fixedly installed on the bottom inner wall of the placing box 12. The connection box 25 is capable of dispersing the steam. An air inlet pipe 23 is fixedly installed on the right inner wall of the connection box 25. The air inlet pipe 23 can transport the steam into the connection box 25, and the right end of the air inlet pipe 23 extends into the dispersion box 11. The right ends of the plurality of shunt pipes 26 all extend into the connection box 25 and are fixedly connected to the left inner wall of the connection box 25. By setting the shunt pipes 26, the area where the steam can be transported upward at the bottom can be enlarged, so that the bottom of the shoe can be transported upward. For fumigation, the top inner wall of the shunt pipe 26 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com