High-frequency triggered direct-current welding power source

A welding power source and high-frequency technology, applied in the field of high-frequency-triggered DC welding power sources, can solve problems such as affecting the stability of the DC arc welding power source, adversely affecting the heat dissipation of power components, affecting the load duration rate of the DC arc welding power source, etc. The effect of heat dissipation, compactness improvement, and energy recovery improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

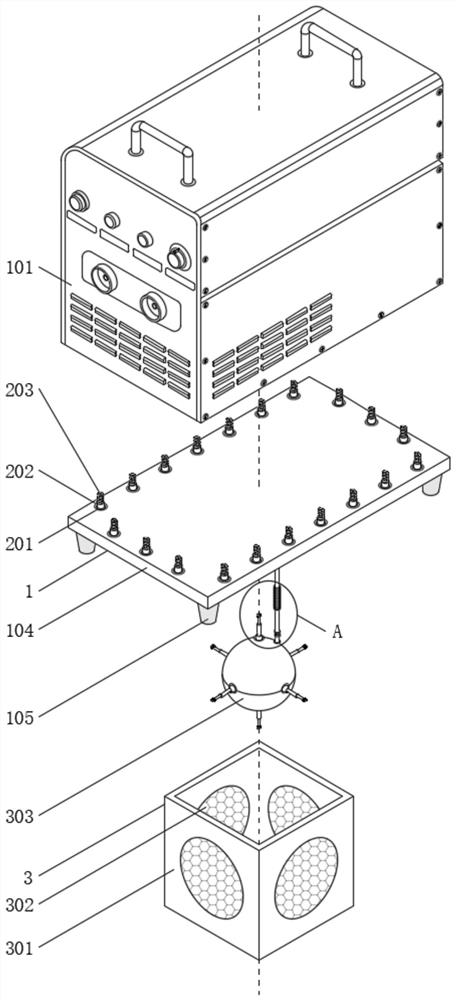

[0042] see Figure 1-8 , the present embodiment discloses a high-frequency triggering DC welding power supply, including an outer protective sound insulation assembly 1, a heat dissipation assembly 2 is arranged inside the outer protection sound insulation assembly 1, and the heat dissipation assembly 2 is used to generate an air vortex, and An air flow filter assembly 3 is also arranged at the position corresponding to the heat dissipation assembly 2 at the bottom of the outer protection sound insulation assembly 1, and an energy conversion assembly 4 is arranged inside the air flow filter assembly 3, and the energy conversion assembly 4 is used to realize the absorption of vibration energy. Digestion and conversion, the energy conversion component 4 communicates with the cooling component 2;

[0043] The heat dissipation assembly 2 includes a first spherical body 209, which is fixedly connected to the surface of the first adapter tube 202, and the surface of the first spheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com