Handheld punching device for steel structure

A drilling device and steel structure technology, applied in drilling/drilling equipment, portable drilling rigs, workbenches, etc., can solve the problems of large overall size, unsuitable single-handed operation, and low drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

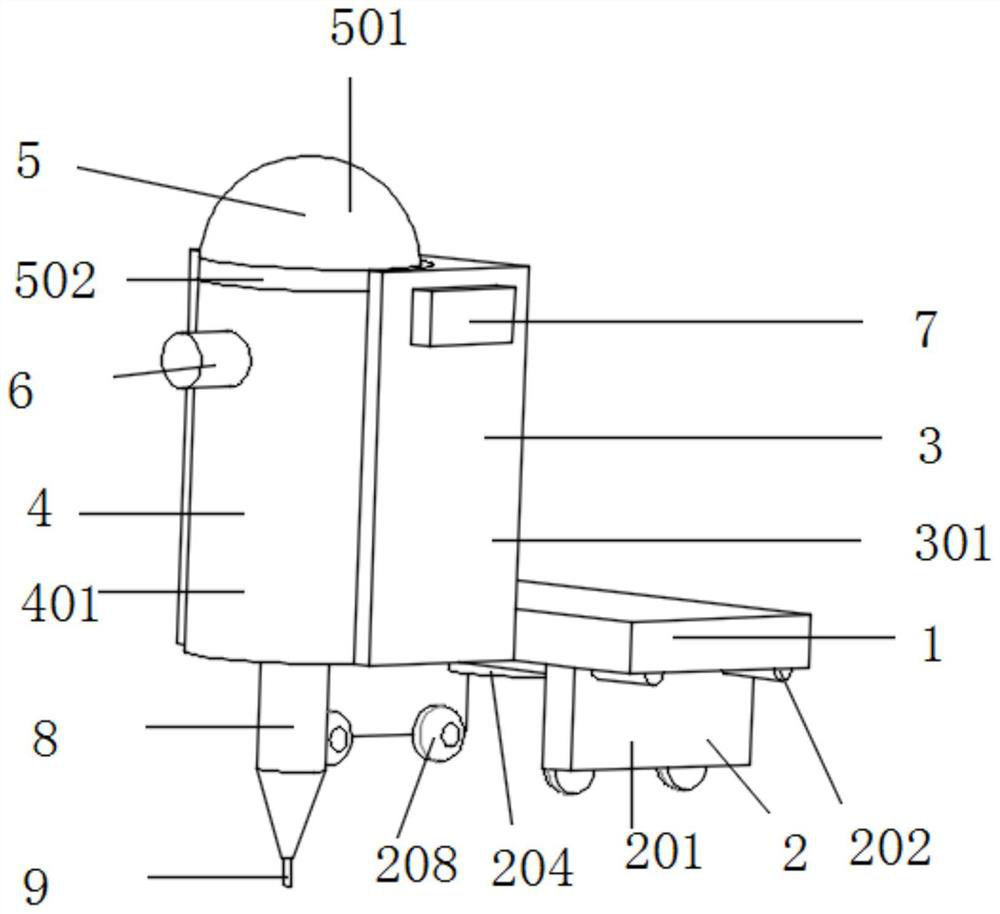

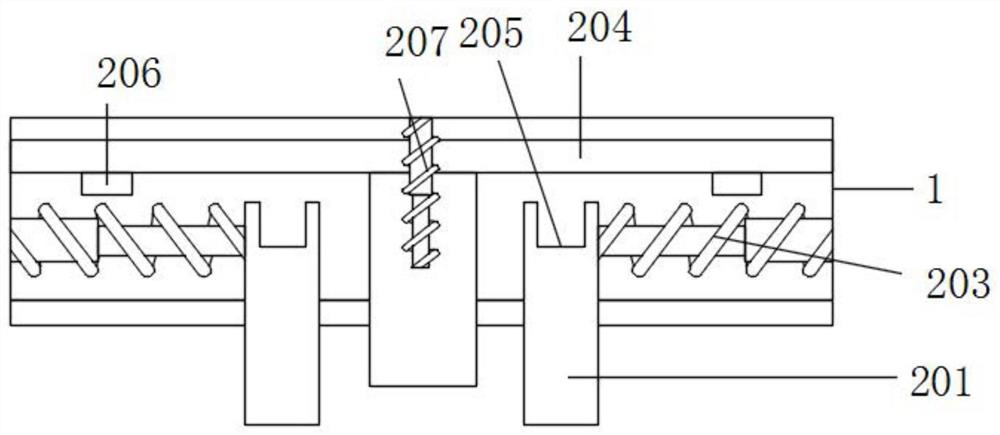

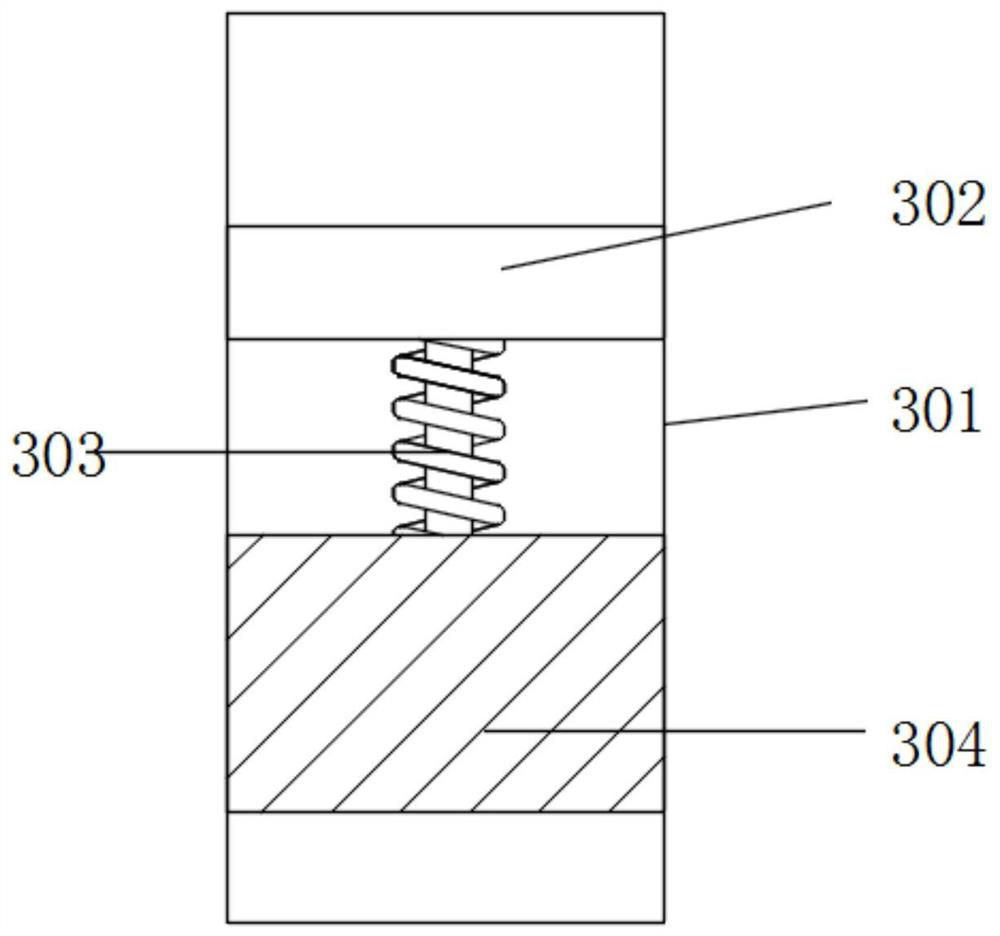

[0026] A hand-held punching device for steel structures, comprising a bottom plate 1, a locking mechanism 3 and a drilling mechanism 4, the locking mechanism 3 is specifically composed of a sliding bin 301, a slider 302, a connecting rod 303 and a strong magnet 304, the The surface of the bottom plate 1 is fixedly connected with a sliding compartment 301, the surface of the sliding compartment 301 is slidably connected with a slider 302, the surface of the slider 302 is welded with a connecting rod 303, and a strong magnet 304 is installed on one side of the connecting rod 303 , the drilling mechanism 4 is specifically composed of a drilling chamber 401, a motor 402, a rotating rod 403, a fan blade 404, a contact gear 405, a large gear 406, a gear 407 and a fixing block and a limit groove 409. The slider 302 The surface is fixedly connected with a drilling chamber 401, the inner wall of the drilling chamber 401 is equipped with a motor 402, the power output end of the motor 402...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com