Ferromagnetic carbon-based composite material, and preparation method and application thereof

A carbon-based composite material and ferromagnetic technology, applied in chemical instruments and methods, alkali metal compounds, and other chemical processes, can solve the problems of magnetic weakening, complicated preparation process, and disappearance, and achieve easy separation, uniform distribution, and magnetic properties. long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

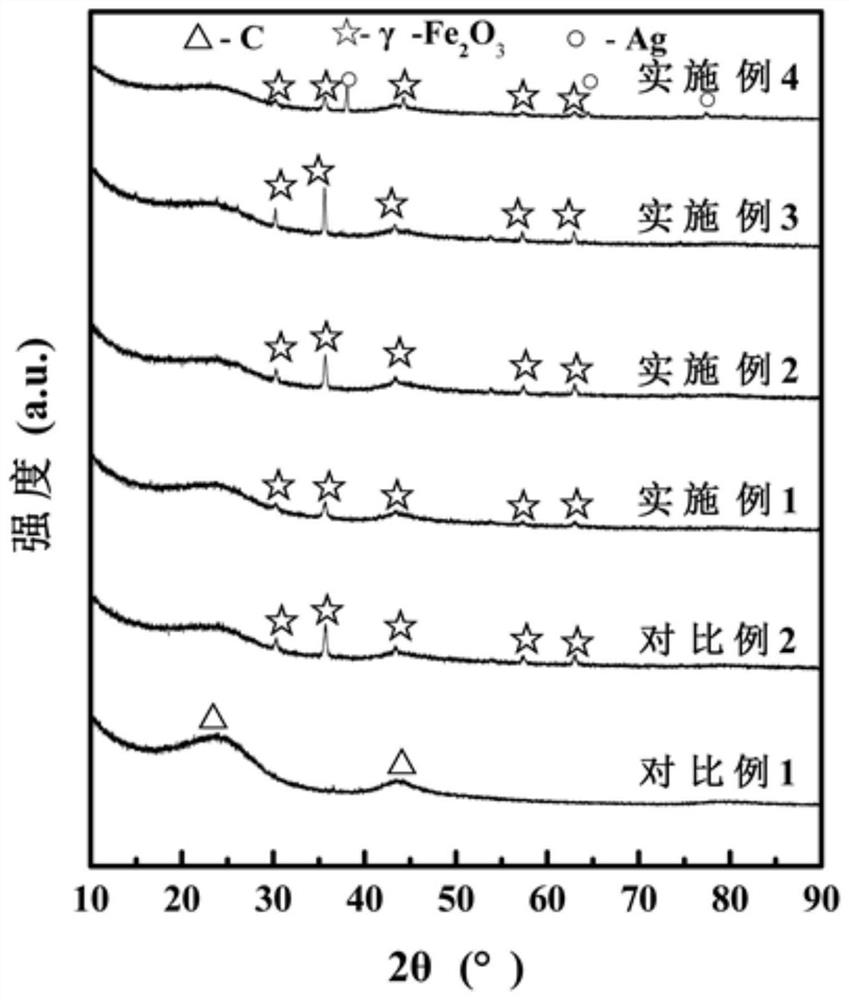

Embodiment 1

[0091] This embodiment provides a method for preparing a ferromagnetic carbon-based composite material, the preparation method comprising the following steps:

[0092] (1) Mix 200 mesh activated carbon with a graphene oxide solution with a mass fraction of 3.5%, the mass ratio of graphene oxide in the activated carbon to graphene oxide solution is 50:1, stir at 60°C for 20min, heat up to 90°C and add The cassava flour linking agent was reacted for 10 minutes, and the suspension after the reaction was left to stand at 25°C, and the solid was obtained by suction filtration after layering, and the solid was dried at 105°C for 20 hours to obtain activated carbon / graphene oxide;

[0093] Wherein, the quality of the linking agent is 20% of the mass of the activated carbon, the linking agent is a linking agent suspension, and the linking agent suspension is ultrasonically treated for 20 min in advance, and the linking agent powder and deionized water in the linking agent suspension ar...

Embodiment 2

[0097] This embodiment provides a method for preparing a ferromagnetic carbon-based composite material, except that FeCl in step (2) 2 The mass of solute in the solution is 1.0% of the activated carbon / graphene oxide mass, and the temperature of the charcoal thermal reaction in step (3) is 800° C., and other conditions are exactly the same as in Example 1.

Embodiment 3

[0099] This embodiment provides a method for preparing a ferromagnetic carbon-based composite material, except that FeCl in step (2) 2 The mass of solute in the solution is 0.5% of the activated carbon / graphene oxide mass, and the temperature of the charcothermal reaction in step (3) is 900° C., and other conditions are exactly the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com