Pretreatment method of wet apple residues for pectin extraction and pectin extraction method

A pectin extraction and apple technology, which is applied in the pretreatment of apple wet residue for pectin extraction, in the field of pectin extraction, can solve the problems of pectin yield and quality to be improved, and achieve the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

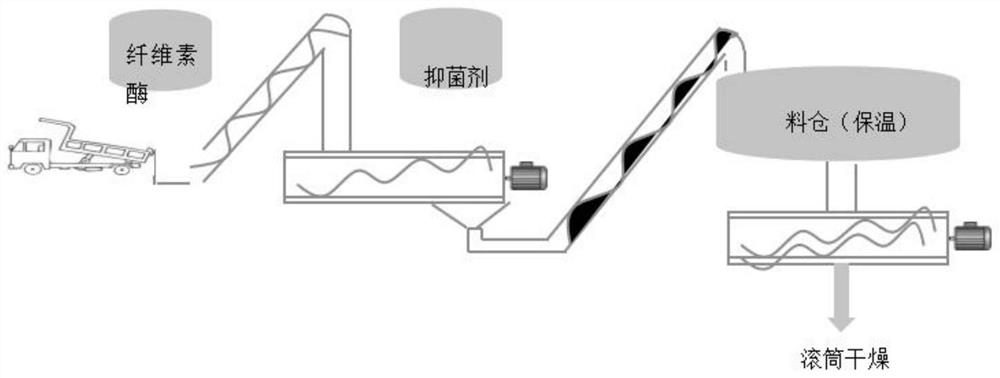

[0059] See flow chart figure 1 .

[0060] 1. After extracting the wet apple pomace with a moisture content of 72%, avoid the accumulation of the pomace and transfer it to the conveying auger in time. During the transportation of the pomace, add 1000ppm of sodium benzoate aqueous solution (0.5% w / w) and 100ppm β-glucanase (1% w / w, enzyme activity unit ≥ 1000u / ml); the pomace is transported to a horizontal coulter mixer with a cooling water jacket, and mixed evenly Finally, ensure that the material outlet temperature is 10°C; the pomace is transported to the silo with rock wool insulation, and kept in the silo for 60mins; The rotation speed is 100rpm. By adjusting the height of the extruder baffle, the moisture content of the pomace is controlled at 61%. The slag is dried, cooled, and sieved by a drum for later use.

[0061] 2. Extraction of pectin: take the dried apple pomace, add it to hot water at 80°C, the ratio of solid to liquid is 1:40, adjust the pH to 2.0 with concen...

Embodiment 2

[0067] 1. After extracting the wet apple pomace with a moisture content of 78%, avoid the accumulation of the pomace and transfer it to the conveying auger in time. During the transportation of the pomace, add 1000ppm of sodium benzoate aqueous solution (0.5% w / w) and 100ppm β-glucanase (1%w / w, enzyme activity unit ≥ 1000u / ml); the pomace is transported to a horizontal coulter mixer with a cooling water jacket, and mixed evenly Finally, ensure that the material outlet temperature is 10°C; the fruit pomace is transported to the silo with rock wool insulation, and kept in the silo for 60mins; the pomace that has undergone antibacterial and enzymatic hydrolysis is transported to the twin-screw extruder to keep The rotation speed is 100rpm. By adjusting the height of the extruder baffle, the moisture content of the pomace is controlled at 65%. The slag is dried, cooled, and sieved by a drum for later use.

[0068] 2. Extraction of pectin: take the dried apple pomace, add it to 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com