Ultrasonic flaw detector with storage box

A technology for flaw detectors and storage boxes, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, and instruments. , not easy to break, make full use of the effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

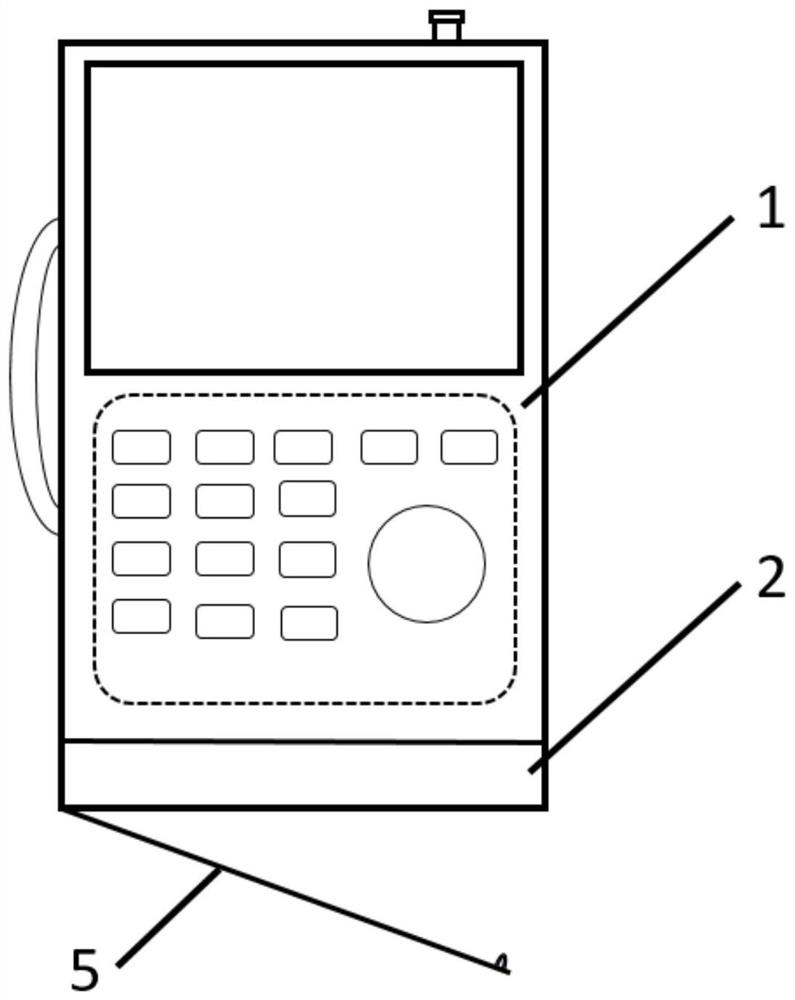

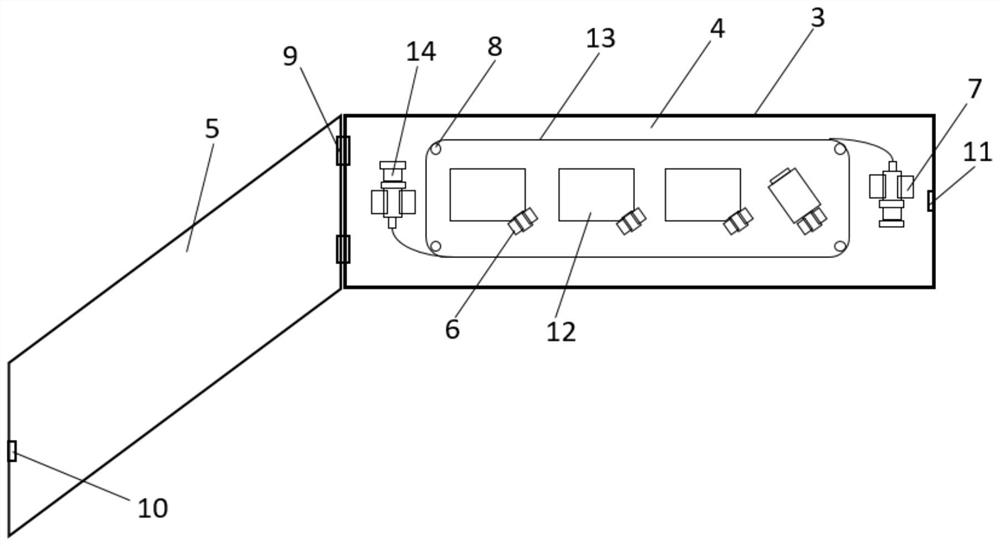

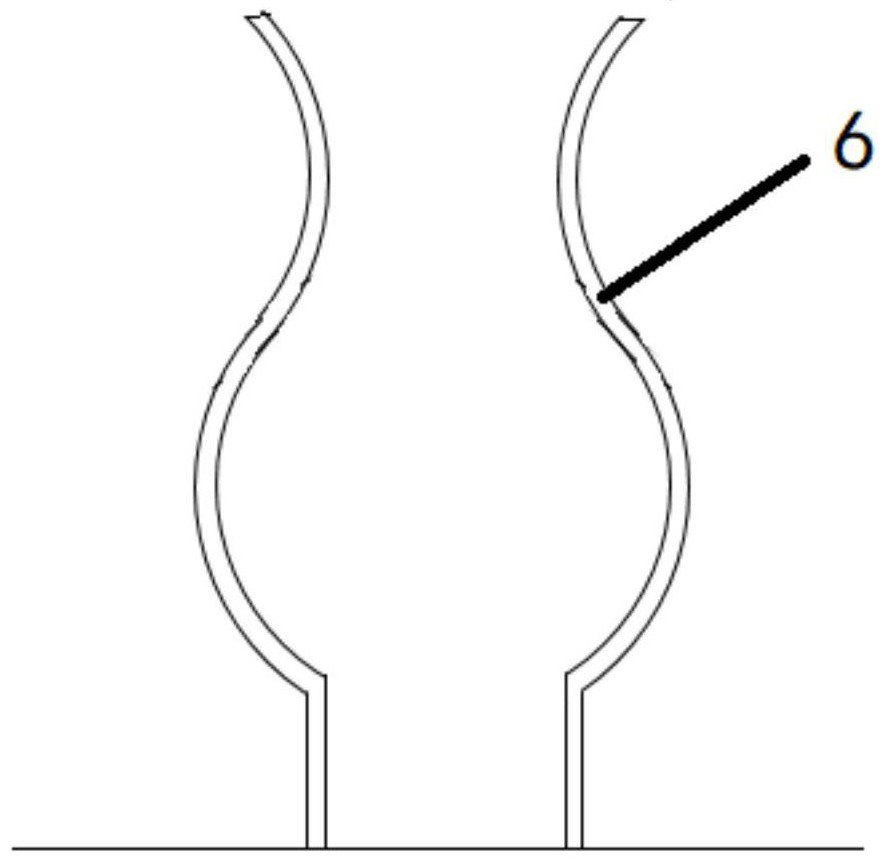

[0033] Such as figure 1 , is the ultrasonic flaw detector with its own storage box of the present invention, comprising a flaw detector body 1 and a storage box 2 arranged at the bottom of the flaw detector body 1; the storage box 2 includes a casing 3 and a cover 5, and the casing 3 and the flaw detector body 1 Connection, the shell 3 and the cover 5 form a closed chamber 4, and the shell 3 and the cover 5 can be opened and closed by a locking mechanism; the chamber 4 is equipped with a number of probe fixing devices 6 and a number of connecting wire joint fixing devices 7 and several winding fixtures 8.

[0034] In a preferred embodiment of the present invention, one end of the housing 3 is hinged to the cover 5 , and the other end is provided with a U-shaped spring buckle 10 , and the corresponding position of the cover 5 is provided with a U-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com