A device for detecting the finished size of shaft forgings

A detection device and finished product size technology, applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problems of low detection efficiency, inaccurate detection results, and the clamping center cannot be aligned with the shaft forgings, etc., so as to improve the detection speed , Reduce the difficulty of detection, and the effect of intuitive detection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

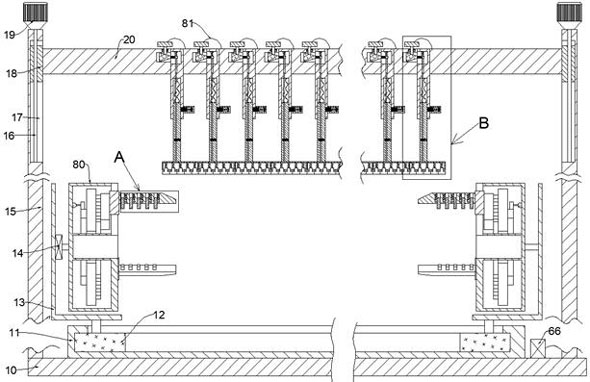

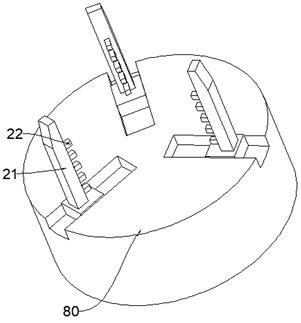

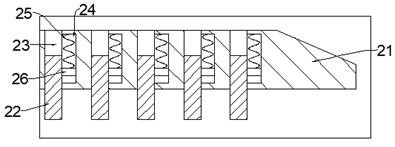

[0023] combined with Figure 1-Figure 7 The device for detecting the finished size of shaft forgings includes a bottom plate 10, on which an electric slide rail 11 is fixed, and two three-jaw chucks 80 are arranged on both sides of the top of the electric slide rail 11, two The two three-jaw chucks 80 are respectively used to clamp the two ends of the shaft forgings. The three-jaw chucks 80 are provided with jaws 21, and each of the jaws 21 of the three-jaw chucks 80 is provided with Both are provided with a receiving groove 23 that runs through the claws 21, and a clamping block 22 is slid in the receiving groove 23, and the three claws 21 of the three-jaw chuck 80 are close to each other to align the shaft forgings. When clamping, it is the clamping blocks 22 on each of the jaws 21 that finally play a clamping effect. Due to the uniform distribution of the clamping blocks 22, the protrusions or depressions on the shaft forging are relatively small for the three-jaw clamps. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com