Modified nano-zinc oxide as well as preparation method and application thereof

A nano-zinc oxide, modified technology, applied in the direction of light-resistant fiber, biochemical fiber treatment, textile and papermaking, etc., can solve the problems of poor toughness, poor protection effect of anti-ultraviolet fabric, etc., and achieve excellent antibacterial and good ultraviolet shielding. Sexual, powerful boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

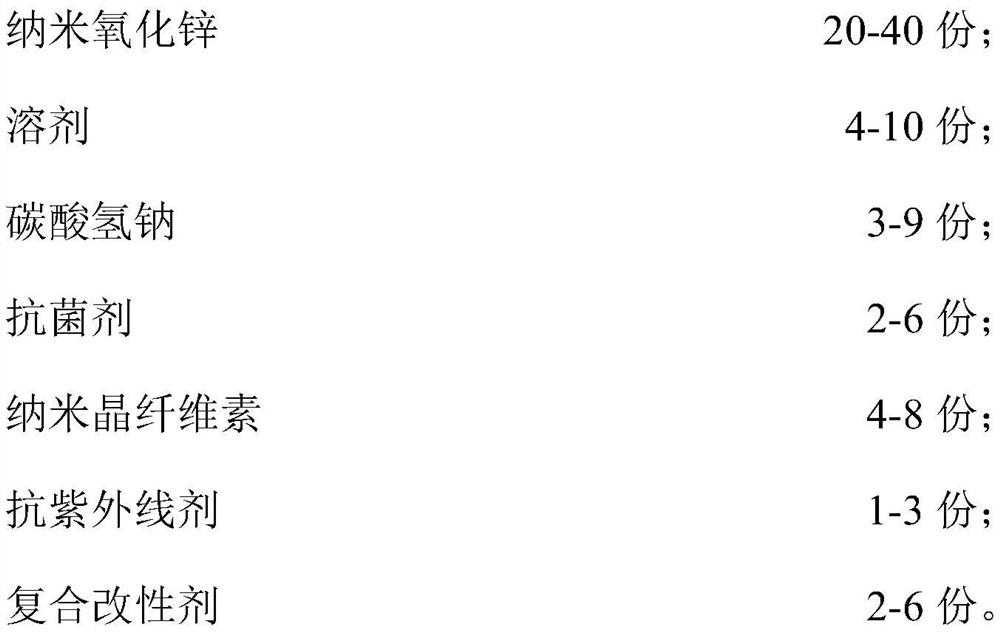

[0049] This embodiment provides a modified nano-zinc oxide, whose raw materials include 20 g of nano-zinc oxide, 4 g of ethanol, 3 g of sodium bicarbonate, 2 g of chitosan, 4 g of nanocrystalline cellulose, 1 g of anti-ultraviolet agent and 2 g of composite modifier.

[0050] Wherein, the anti-ultraviolet agent is composed of 30% by weight of vinyl chloride-vinyl acetate copolymer emulsion, 20% by weight of 2,4-dichlorobenzoic acid, 20% by weight of microporous lignin, and 20% of nanometer titanium dioxide.

[0051] The composite modifier is sodium ricinoleic acid ester sulfate, sodium aluminum sulfate dodecahydrate, graphene oxide-attapulgite, and the mass ratio is 1:1:0.5.

[0052] The specific preparation method is as follows:

[0053] (1) First put nano-zinc oxide, ethanol, and sodium bicarbonate into a stirring tank for heating and dispersing. The dispersion temperature is 45° C., the stirring speed is 600 rpm, and the time is 12 minutes to obtain a nano-zinc oxide disper...

Embodiment 2

[0059] This embodiment provides a modified nano-zinc oxide, whose raw materials include 40g of nano-zinc oxide, 10g of ethanol, 9g of sodium bicarbonate, 6g of chitosan, 8g of nanocrystalline cellulose, 3g of anti-ultraviolet agent and 6g of composite modifier.

[0060] Wherein, the anti-ultraviolet agent is composed of 30% by weight of vinyl chloride-vinyl acetate copolymer emulsion, 20% by weight of 2,4-dichlorobenzoic acid, 20% by weight of microporous lignin, and 20% of nanometer titanium dioxide.

[0061] The composite modifier is sodium ricinoleic acid ester sulfate, sodium aluminum sulfate dodecahydrate, graphene oxide-attapulgite, and the mass ratio is 1:1:0.5.

[0062] The specific preparation method is as follows:

[0063] (1) First put nano-zinc oxide, ethanol, and sodium bicarbonate into a stirring tank for heating and dispersing. The dispersion temperature is 55° C., the stirring speed is 800 rpm, and the time is 22 minutes to obtain a nano-zinc oxide dispersion; ...

Embodiment 3

[0069] This embodiment provides a modified nano-zinc oxide whose raw materials include 25 g of nano-zinc oxide, 5 g of ethanol, 4 g of sodium bicarbonate, 3 g of chitosan, 5 g of nanocrystalline cellulose, 2 g of an anti-ultraviolet agent and 3 g of a composite modifier.

[0070] Wherein, the anti-ultraviolet agent is composed of 30% by weight of vinyl chloride-vinyl acetate copolymer emulsion, 20% by weight of 2,4-dichlorobenzoic acid, 20% by weight of microporous lignin, and 20% of nanometer titanium dioxide.

[0071] The composite modifier is sodium ricinoleic acid ester sulfate, sodium aluminum sulfate dodecahydrate, graphene oxide-attapulgite, and the mass ratio is 1:1:0.5.

[0072] The specific preparation method is as follows:

[0073] (1) First put nano-zinc oxide, ethanol, and sodium bicarbonate into a stirring tank for heating and dispersing. The dispersion temperature is 46° C., the stirring speed is 650 rpm, and the time is 13 minutes to obtain a nano-zinc oxide di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com