Preparation method of mixed bacterium enzyme liquid for efficiently hydrolyzing waste distiller's grains of white spirit

A technology of mixing bacteria and enzyme liquid, applied in the direction of microorganism-based methods, biochemical equipment and methods, fungi, etc., can solve the problems of poor hydrolysis effect and high cost of enzymatic hydrolysis process, and achieve improved capacity, improved permeability, The effect of increasing adaptive capacity for selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

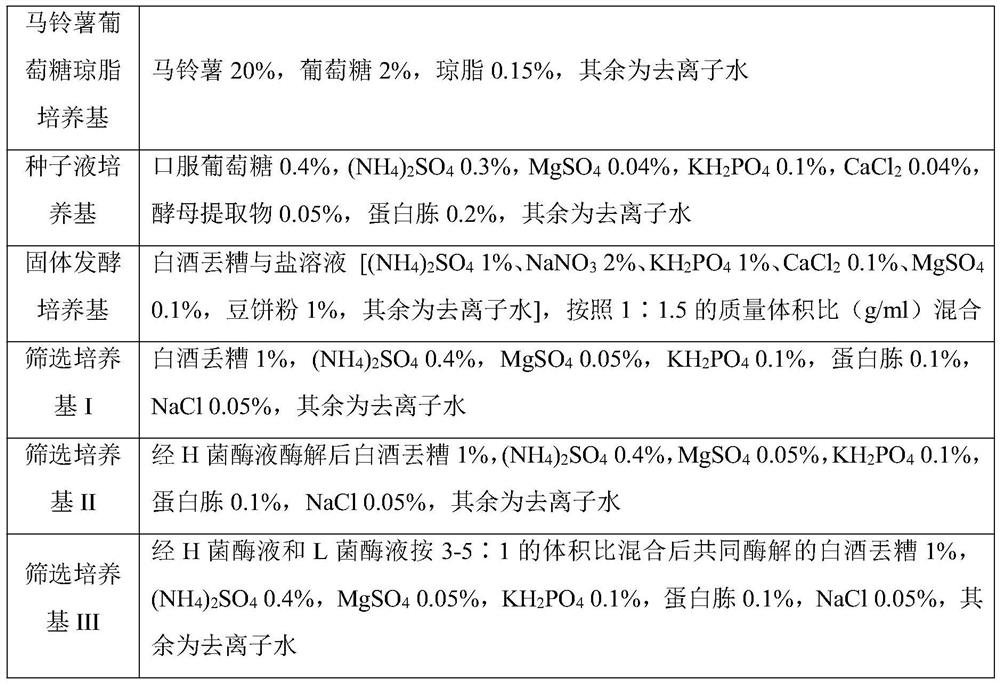

[0028] The preparation method of the mixed bacteria enzyme solution for efficiently hydrolyzing liquor discarded grains comprises the following steps:

[0029] a. Take samples from pit mud, waste grains, and surrounding soil of the winery, use the screening medium with liquor waste grains as the carbon source to screen and enrich, and obtain bacterial samples after separation and purification;

[0030]b. Activate the bacterial sample obtained in step a, carry out fermentation and culture, then extract it, filter it with suction, and centrifuge to obtain bacterial enzyme solution A, use bacterial enzyme solution A to enzymolyze liquor discarded grains, and screen to obtain H bacteria , the H bacteria enzyme liquid is obtained by fermentation, and the enzyme activity of the H bacteria enzyme liquid is 5.0-5.8IU / ml;

[0031] c. Sampling was taken from pit mud, distilled grains, and surrounding environmental soil of the winery, and screened and enriched with the screening medium u...

Embodiment 1

[0057] A. Disposal of grains: Rinse liquor grains with tap water, filter them with suction, and dry them to obtain dry grains;

[0058] B. Enzymolysis of discarded grains: mix the dried discarded grains with the mixed enzyme solution according to the mass volume ratio of 1:10g / ml, shake at 50°C and 140rpm at a constant temperature for 64 hours, and obtain the enzymatic sugar solution after suction filtration;

[0059] C. Inspection: The concentration of reducing sugar in the enzymatic hydrolyzed sugar solution is 50g / L, corresponding to 0.54g of reducing sugar per gram of dry waste.

Embodiment 2

[0061] A. Disposal of grains: Rinse liquor grains with tap water, filter them with suction, and dry them to obtain dry grains;

[0062] B. Enzymatic hydrolysis of discarded grains: mix the dried discarded grains with the mixed enzyme solution according to the mass volume ratio of 1:10g / ml, shake at a constant temperature of 50°C and 140rpm for 72h, and obtain the enzymatic sugar solution after suction filtration;

[0063] C. Inspection: The concentration of reducing sugar in the enzymatic hydrolyzed sugar solution is 47g / L, corresponding to 0.51g of reducing sugar per gram of dry waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com