Supramolecular fracturing fluid based on modified polyacrylamide and preparation method thereof

A polyacrylamide and acrylamide technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of large amount of surfactant, harsh preparation conditions and high cost, and achieve good resistance to divalent salts, It is easy to popularize and apply, and the effect of on-site preparation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A supramolecular cleaning fracturing fluid based on modified polyacrylamide and anionic surfactant, the specific preparation steps are as follows:

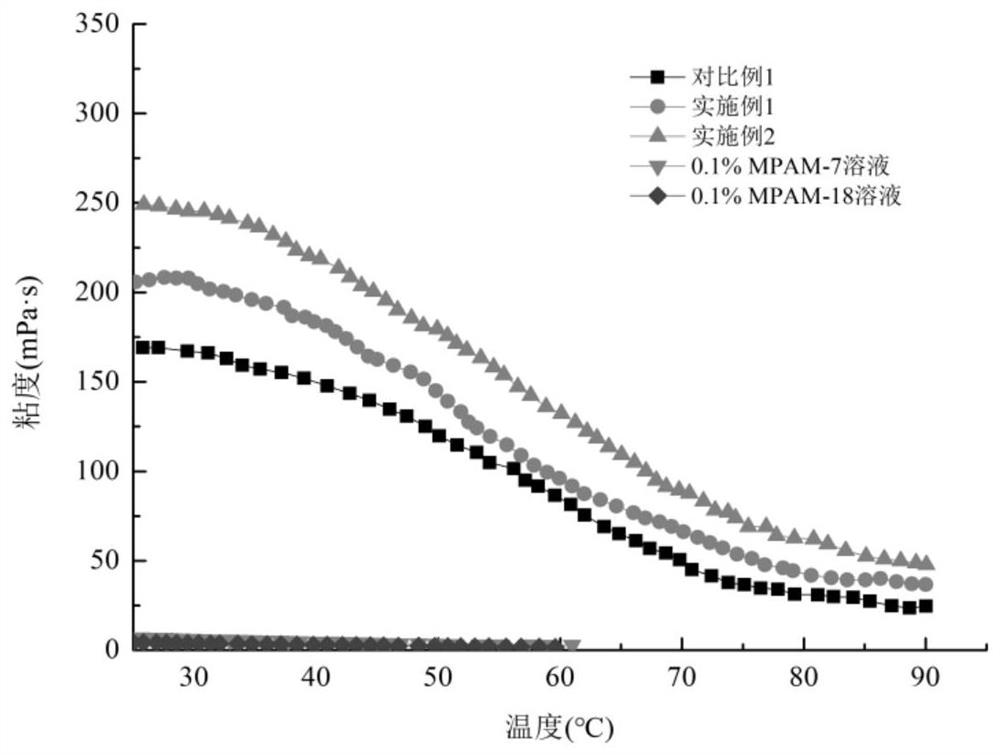

[0051] S1. According to the molar ratio of acrylamide, sodium acrylate, and functional monomer acryloxyethyl benzyl dimethyl ammonium chloride, the molar ratio is 85:15:1, and the modified polyacrylamide MPAM is prepared by aqueous solution polymerization- 7. The molecular weight is 4 to 5 million.

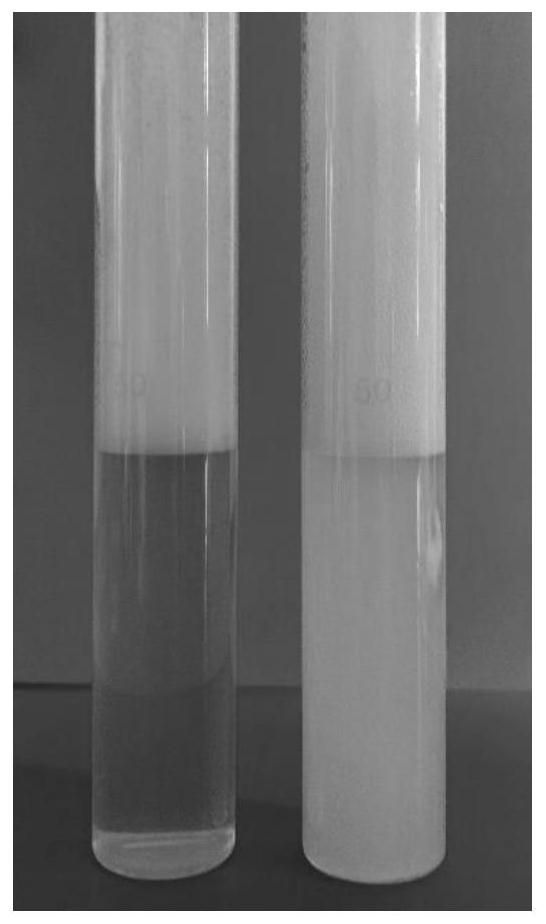

[0052] S2. the purified anionic surfactant sodium oleic acid ethyl sulfonate is dissolved in methanol of equal mass to make a pre-solution of mass fraction 50%; get the modified polyacrylamide MPAM prepared in 0.4g S1- 7 Dissolve in 300g of water, then add 3.2g of benzyltrimethylammonium chloride and 16g of pre-solution in sequence, and dissolve evenly to obtain solution A; dissolve 16g of potassium chloride in 100g of water to obtain solution B, and add solution B to the solution Stir evenly in A to form a viscoelastic supram...

Embodiment 2

[0054] A supramolecular cleaning fracturing fluid based on modified polyacrylamide and anionic surfactant, the specific preparation steps are as follows:

[0055] S1. According to the molar ratio of acrylamide, sodium acrylate, and functional monomer acryloxyethyl octadecyldimethylammonium chloride of 85:15:0.5, the modified polyacrylamide is prepared by aqueous solution polymerization MPAM-18, molecular weight 4-5 million.

[0056] S2. the purified anionic surfactant sodium oleic acid ethyl sulfonate is dissolved in methanol of equal mass to make a pre-solution of mass fraction 50%; get the modified polyacrylamide MPAM prepared in 0.4g S1- Dissolve 18 in 300g of water, then add 3.2g of benzyltrimethylammonium chloride and 16g of pre-solution in sequence, and dissolve evenly to obtain solution A; dissolve 16g of potassium chloride in 100g of water to obtain solution B, and add solution B to the solution Stir evenly in A to form a viscoelastic supramolecular cleaning fracturin...

Embodiment 3

[0058] A supramolecular cleaning fracturing fluid based on modified polyacrylamide and anionic surfactant, the specific preparation steps are as follows:

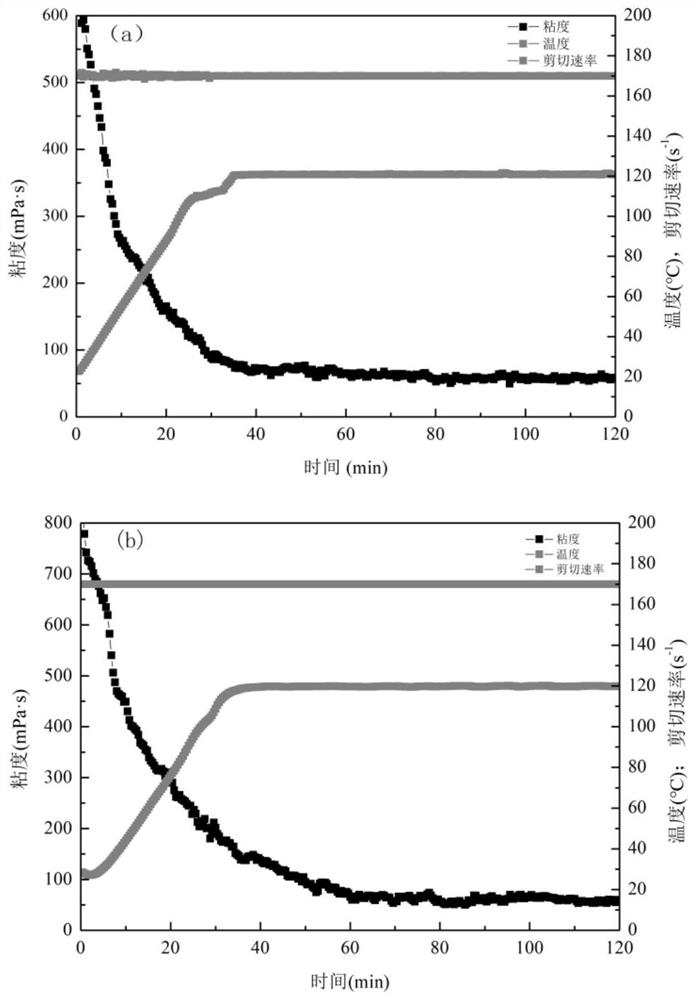

[0059] S1. According to the molar ratio of acrylamide, sodium acrylate, and functional monomer acryloxyethyl octadecyldimethylammonium chloride of 85:15:0.5, the modified polyacrylamide is prepared by aqueous solution polymerization MPAM-18, molecular weight 4-5 million.

[0060] S2. Dissolve the purified anionic surfactant sodium erucamide propyl sulfonate in isopropanol of equal mass to make a pre-solution with a mass fraction of 50%; get the modified polyacrylamide MPAM prepared in 0.8g S1 -18 was dissolved in 250g of water, then sequentially added 8g of benzyl dihydroxyethyl methyl ammonium chloride, 30g of pre-solution, and dissolved uniformly to obtain solution A; 20g of potassium chloride was dissolved in 150g of water to obtain solution B, and the solution Add B into solution A and stir evenly to form a viscoelasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com