Light diffusion type organic silicon composite material and preparation method thereof

A composite material and silicone technology, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem that the haze and light transmittance cannot meet the requirements at the same time, and achieve the product Flexible and diverse forms, convenient construction and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Mix 100 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 1500mPa·s, 10 parts of polydimethylsiloxane with a viscosity of 350mPa·s, and 10 parts of fumed silica (brand: Wacker V-15) and 0.03 parts of phthalocyanine blue were added to the reaction vessel, stirred for 30 minutes under negative pressure of -0.085MPa; component A was obtained;

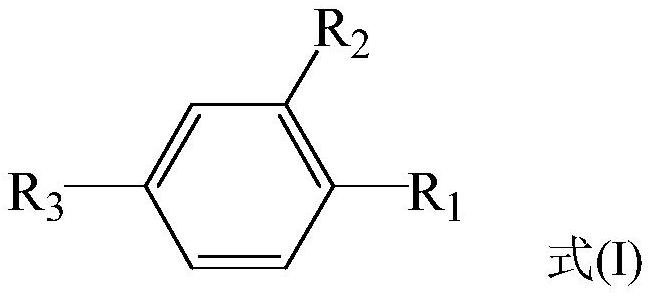

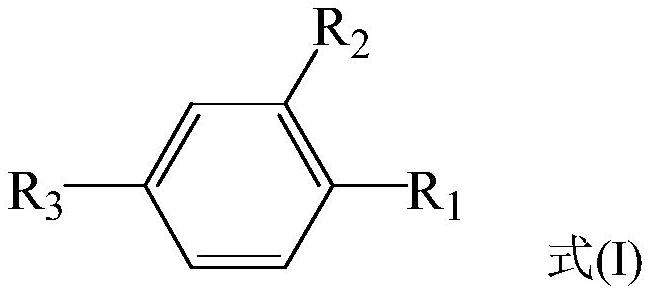

[0040] 2) Add 8 parts of ethyl orthosilicate, 30 parts of dioctyl phthalate (light diffusing agent of formula I structure), and 1 part of dibutyltin dilaurate into the reaction vessel, under the negative pressure of -0.085MPa Stir for 15min to obtain component B;

[0041] 3) Mixing component A obtained in step 1) and component B obtained in step 2) to obtain the light-diffusing silicone composite material.

Embodiment 2

[0043] The rest are the same as in Example 1, except that the amount of light diffusing agent dioctyl phthalate is 20 parts.

Embodiment 3

[0045] The rest are the same as in Example 1, except that the amount of light diffusing agent dioctyl phthalate is 50 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com